Hardscaping >>> Case Study

Caring for Hardscapes in Cold Climates

The Effects Deicing Salt Can Have On Pavers

Every year in the northern United States, homeowners, business owners and public employees spread deicing salts on roads and walkways to melt snow and ice. While these salts can effectively eliminate slippery conditions, they also may adversely affect landscaping and hardscaping pavers by causing visual and structural damage. However, properly manufactured pavers can resist the degradation caused by the salts.

Withstanding cold climate conditions

Interlocking concrete pavers typically perform better in colder climates than rigid asphalt and solid concrete surfaces. “The high compression, low absorption rates of pavers make them more resistant to deicing agents,” says Len Browning, technical advisor for Belgard Hardscapes by Oldcastle.

Resistance to salts is related directly to a low absorption rate and a high compressive strength, and pavers generally outperform solid concrete and asphalt in both areas.

“The quality of aggregate materials used to manufacture pavers is an important component in the performance of pavers and their resistance to deicing salts,” says Browning. “Belgard sources aggregate materials that are high strength with low absorption rates, and no deleterious material that may contaminate the finished product.”

This produces a high-quality, salt-resistant surface that withstands extreme weather better than other surfaces.

This produces a high-quality, salt-resistant surface that withstands extreme weather better than other surfaces.

Additionally, pavers withstand expansive soils and freeze-thaw movement better than rigid asphalt and solid concrete, which often crack under this type of shifting. Water can enter these cracks, and subsequent freeze-thaw cycles that cause the trapped to water to freeze and expand can cause additional damage to paved surfaces. By contrast, pavers shift with the movement of the ground, avoiding cracking and consequential damage. Properly constructed pavers create a flexible, load-bearing surface that can accommodate ground movements without sustaining damage.

According to the Herndon, Va.-based Interlocking Concrete Pavement Institute (ICPI) Technical Committee, concrete pavers have these advantages over ready-mixed concrete:

- Stronger aggregate bonding from higher cement content than typically used in pavement quality concrete

- Smaller aggregates for more surface area for the cement to bond

- Lower water-to-cement ratio, and vibration and compaction during the manufacturing process to increase aggregate-cement contact and eliminate overwatering

- Produced in a highly controlled manufacturing plant, leading to lower variation in material properties and eliminating surface over-finishing

- Can be successfully installed in cold weather, since they are cured before leaving the manufacturing plant.

Understanding the industry standard

Lou Mangiaracina, VP of sales in the Northeast for Belgard, has witnessed the effects that excessive use of deicing salts can have on pavers. “I’ve seen salt damage pavers in as little as three years,” says Mangiaracina. “After a while, salt buildup can disintegrate pavers, if they are not properly manufactured and maintained.”

Contrary to some consumer misperceptions of industry advertising claims, no paver is truly deicing salt proof, although most are deicing salt resistant. Fortunately, ways to extend the lifespan and appearance of pavers, even where salts are used, do exist.

The American Society for Testing Materials (ASTM) C936/C936M – 09 defines the industry manufacturing standard for solid concrete interlocking pavers. This Standard Specification requires, in part:

- An average absorption no greater than 5 percent

- An average compressive strength of 8,000 pounds psi

- No greater mass loss than 200 g/m2 when subject to 25 freeze-thaw cycles

- No greater mass loss than 500 g/m2 when subject to 50 freeze-thaw cycles.

In areas where pavers are exposed to freezing and deicing materials during their service, ASTM C936/C936M – 09 requires testing the pavers in 3 percent saline solution to replicate the effects of deicing salts. When companies meet ASTM requirements, their pavers are considered resistant to deicing salts. Pavers from Belgard, for example, exceed this standard and are deicing salt resistant, but that does not make them deicing salt proof. In fact, no company’s pavers are deicing salt proof.

One challenge the paver industry faces is potentially confusing advertising that can cause contractors, hardscapers and homeowners to believe that some branded pavers are guaranteed to be unaffected by deicing salts. Product statements such as “deicing salt resistant,” while technically true, also can be misunderstood.

“Customers sometimes take ‘deicing salt resistant’ to mean ‘deicing salt proof,’” says Daniel Moreland, a Belgard architectural representative for Anchor Concrete Products in Easton, Pa. “But there is a big difference between deicing salt resistant and proof.”

Another claim sometimes misread by hardscape professionals and homeowners is a warranty that covers against the abnormal deterioration of a surface due to sodium chloride (NaCl), such as deicing salt. Such warranties cover only abnormal deterioration, which is damage that would exceed the allowances made in ASTM C936/C936M – 09.

To eliminate confusion, manufacturers should explain carefully their guarantees to customers. For example, if pavers do sustain deicing damage, warranties typically don’t cover items such as labor costs to replace them, shipping costs for the replacement pavers, and color matching. Professionals and homeowners who believe their pavers are protected against any and all damage caused from deicing salts could be unpleasantly surprised.

Safeguard against damage

One of the best ways to protect pavers is to minimize their exposure to deicing salts. Although people tend to believe that more salt equates to better melting abilities or less frequent applications, excessive salting can harm the pavers. If salt ends up in piles or clumps, then it has been applied too heavily.

According to the ICPI, “The key to successfully using deicing materials is to use only as much [salt] as is needed to do the job. This will maximize paver benefits, while minimizing any damage to the concrete pavers and surrounding environment.”

The ICPI Technical Committee recommends these guidelines to limit the exposure to deicing:

- Mix the salt with sand, which is visible and the traction can be felt underfoot

- Follow the recommended application and don’t over-apply the salt

- Use deicing salt for melting ice, not for snow removal

- Remove the ice once it’s loose to avoid salt buildup

- Wash off the pavers in the spring, since the salt can continue to cause degradation even after the ice or snow has melted.

Routine maintenance can minimize the effects of deicing salts. As Moreland points out, “The bottom line is that every exterior surface needs some maintenance. Whether you live in the North and use deicing salts, the extremities of acid rain, pollution and vehicular traffic cause wear and tear on exterior surfaces.”

To maximize the life-cycle benefits of an interlocking concrete paver system, Moreland recommends using sealers. In addition to creating certain preferred looks, sealers may provide some protection against deicing salts, acid rain and lawn chemicals.

“Quality pavers are designed and manufactured to look attractive and perform for years and even decades, but professionals and homeowners can help extend the life of their hardscapes by cleaning and then sealing them regularly,” Moreland says.

With proper salting applications and routine maintenance, pavers will look attractive, resist degradation and provide a durable surface for decades.

| Questions Contractors Should Ask |

Before buying pavers, landscaping and hardscaping contractors should ask these questions to manufacturers:

|

| Questions Homeowners Should Ask |

The end consumers should be aware of the type of pavers they’re buying, how the pavers are affected by deicing salts and natural elements, and maintenance requirements. Homeowners and business owners should ask their contractors:

|

Hardscaping >>> Case Study

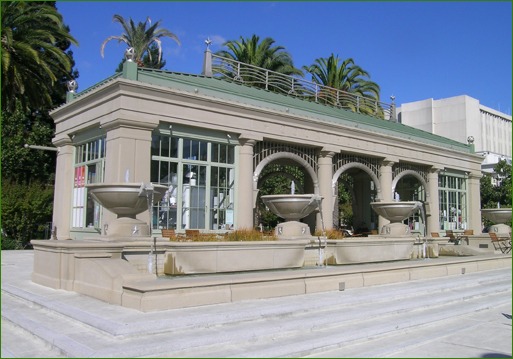

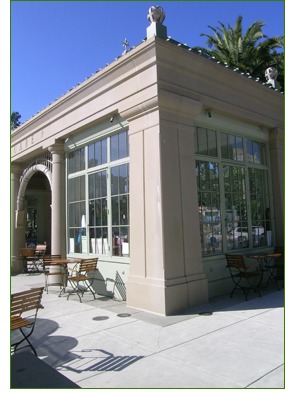

California’s Redwood City Courthouse Square

Redwood City Courthouse Square in California is the perfect union of historic and contemporary design, creating a beautifully open space for the public and community events. Courthouse Square was created on a parcel of land that was formerly occupied by the courthouse annex, which blocked the restored historic 1800s courthouse entry. Removing the courthouse annex created a unique opportunity to design a new entry space to the courthouse as well as a public plaza.

Redwood City Courthouse Square in California is the perfect union of historic and contemporary design, creating a beautifully open space for the public and community events. Courthouse Square was created on a parcel of land that was formerly occupied by the courthouse annex, which blocked the restored historic 1800s courthouse entry. Removing the courthouse annex created a unique opportunity to design a new entry space to the courthouse as well as a public plaza.

The team

The Carlile•Macy design team of Santa Rosa California created a historic-based design reflecting the architectural character of the restored courthouse. The contractor was DPR Construction Inc., which directed, constructed and facilitated the vision. Architectural Facades Unlimited provided the architectural precast. Sullivan/Thompson Masonry & Restoration were the masonry installers of the precast and glass fiber reinforced cement (GFRC).

The challenge

Architectural Facades Unlimited created the precast elements (see images) of the plaza, which features one of the two semi-enclosed cafe pavilions, along with decorative fountains. The process involved creating from a two-dimensional drawing, a three-dimensional object, which is always challenging, provoking and rewarding.

Architectural Facades Unlimited created the GFRC wall panels, columns, signage, lintels, stair tread, precast fountains and fountain bowls from the Carlile • Macy design specifications.

The result

All of the hard work and creativity resulted in a stunning, historic-contemporary urban environment for the full enjoyment of all who visit.

Accolades

The project won the Congress for New Urbanism 2007 Charter Award for Block, Street & Building Design. More can be seen on this project by visiting www.carlilemacy.com/portfolio_detail.aspx?gid=6&giid=72.

Hardscaping >>> Case Study

Seating Repair at University of Wisconsin-River Falls

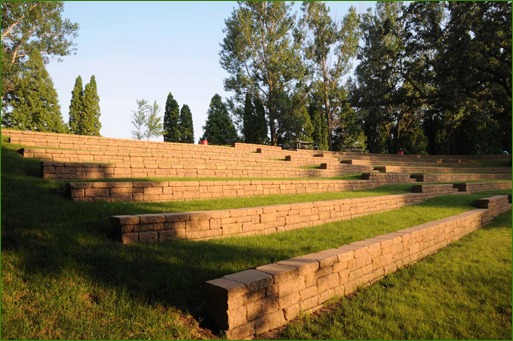

A popular outdoor amphitheatre on the campus of the University of Wisconsin-River Falls (UWRF) got a new lease on life last year, when crumbling limestone seating tiers were replaced with Versa-Lok seat walls and integrated stairs.

Nothing beats sitting outside on a beautiful summer’s eve listening to music or enjoying a play. That’s what Dr. Melvin Wall envisioned for the campus of UWRF in the 1960s, after he and his wife toured Northern Italy and fell in love with an amphitheatre built in the Greco-Roman style. Wall, chairman of the university’s Plant and Earth Science Department and head of the Campus Planning Committee, took the idea to the administration and garnered the support of the president.

Wall proposed that an outdoor amphitheatre be built on the south end of the campus near South Fork, or “Pete’s Creek.” He enlisted the help of students, the administration and alumni, and a former student ponied up a $20,000 matching grant. Hundreds of students, faculty and friends of the university worked in mud to level the area and haul in large limestone blocks to create the seating tiers.

But the elements took their toll on the amphitheatre, according to Joe McIntosh, UWRF grounds supervisor.

“Over time, the limestone had kind of deteriorated, so we put in a proposal to have it redone,” McIntosh explains. “We looked at a couple of different types of natural stone and also the Versa-Lok product. The natural stone was out of our budget range, so we went with the Versa-Lok.”

The project began in Spring 2009 and was completed later that summer. The removal of the limestone blocks and installation of the new seat walls presented some challenges. Two massive oak trees shade the center of the facility and had to be preserved.

“We took some protective measures and tried to keep the contractors away from them as much as we could,” says McIntosh. “Then we gave them some product to enhance their root system. So far, they look pretty good.”

The seat walls were built using Versa-Lok’s Weathered Mosaic segmental retaining wall system, which employs three shapes of blocks in a four-unit panel to create a random-pattern appearance. The product’s weathered texture more closely resembles the natural limestone it replaced.

The long, arcing seat walls are more than 1,400 feet long and about 1.5 feet tall. Stairs are integrated into the seating tiers at several points. More than 3,000 square feet of Versa-Lok were used on the project.

The old limestone was put back into service after it was removed from the amphitheatre’s seating, says McIntosh.

“We saved most of it and have it stored,” he says. “We’ve been using it fairly steadily the past couple of years on some small landscaping projects around campus.” Some of it was even returned to the amphitheatre and used in the stair landings.

The Melvin Wall Amphitheatre rehabilitation project was completed in Fall 2009 and landscaping was finished the following year. Total project cost was around $150,000. It remains the only outdoor amphitheatre on any Wisconsin college campus and one of the few in the country located on a campus.

Design on this project was done by Cedar Corporation, the contractor was Pember Excavating, and the manufacturer was Willow Creek Concrete Products.

Karl Bremer is editor for VERSA-LOK Retaining Wall Systems, www.versa-lok.com.