Words: Don Foster and Mike Walker

Photos: Masonry Cosmetics, Inc.

How often do you think about how strong a brick is? Better said, what is the compressive strength of a typical brick? Tests can be run to tell us that information, with meeting or exceeding ASTM minimum requirements as a goal.

What if I were to tell you that brick far exceeds the ASTM minimum requirements? Better yet, let’s hear from an expert in the field on that subject.

Allow me to introduce to you Mike Walker, Research Associate and the ASTM Service Testing Manager for the National Brick Research Center (NBRC) at Clemson University. NBRC advances the technology of clay brick materials and products, as well as augment the education of ceramic and materials engineering students, and will serve individuals in the brick industry with a resultant increase and improved use of structural clay building products.

I personally have had the pleasure and opportunity to tour their facility and see all the different types of testing they do there, it is very impressive. Mike is lab certified and is extremely knowledgeable in so many areas. Here is what Mike has to share on the subject.

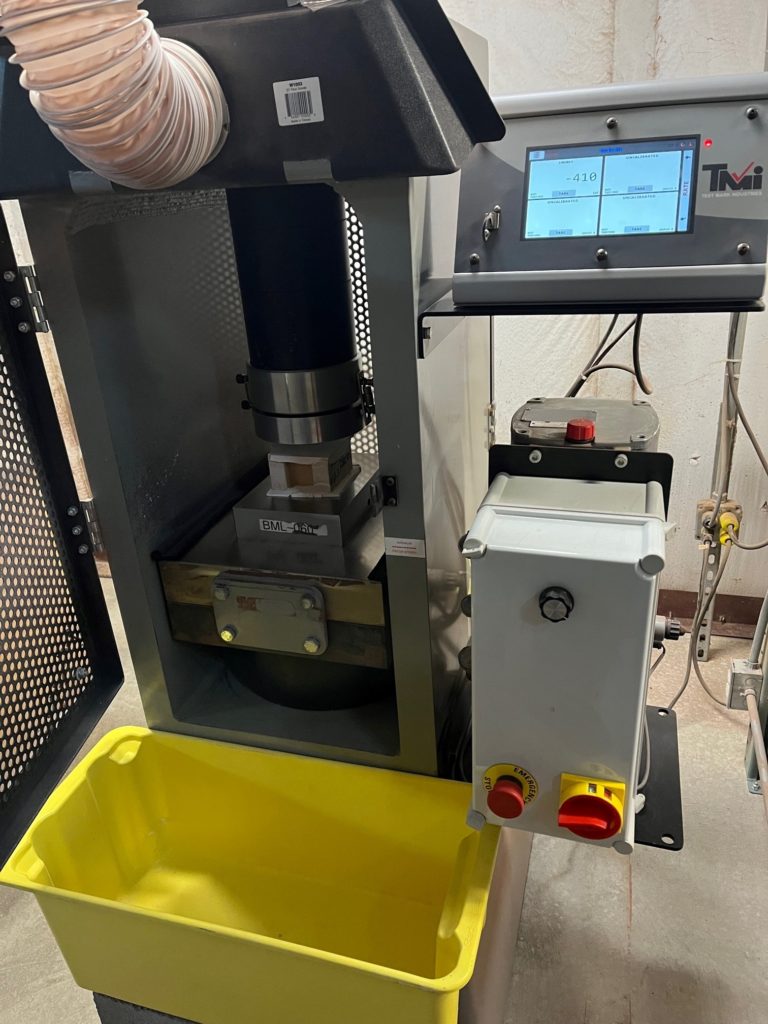

Fired ceramics have been historically noted for their durability and compressive strength. At the National Brick Research Center (NBRC), we receive requests to test facing brick for compliance with the minimum requirements in ASTM C216 Standard Specification for Facing Brick (Solid Masonry Units Made from Clay or Shale). One of the most important properties that are tested to help predict how facing brick will hold up over time is the compressive strength of the brick. One of the requirements for durability is that each brick must be able to carry a compressive load of at least 2500 pounds per square inch (PSI). This means you should be able to put a load of at least 69,000 pounds on a normal modular size brick without it crushing.

What we find is that most of the bricks we test are well beyond what ASTM requires for compressive strength. To meet the other requirements of the ASTM standard for absorption and saturation coefficient, many of the manufacturers must fire to higher temperatures or keep the brick at high temperatures for longer to reduce the porosity of the product and thereby lower the absorption properties. This also tends to increase the density and create stronger bonds between particles in brick, which increases the compressive strength of the brick.

As mentioned earlier, the fired brick strength must be at least 2,500 PSI per the ASTM standard. The average compression strength for fired-facing brick tested by NBRC is around 14,500 PSI. This means that the average load capacity of a modular size brick is approximately 400,000 lbs. Manufactures have quality controls in place to produce a consistent, quality product and they send the brick to NBRC for confirmation that the brick meets ASTM requirements.

And guess what? Fired brick pavers are typically even stronger! But that is a discussion for another day.

This is just one example showing the important role the NBRC plays in the Masonry Industry. I am reminded of a story that has been shared a few times with me over the years. It was a story of only using half a brick when running the compressive strength test in the machine. This was because of the strength of brick, if they used the whole brick, it would damage or break the machine.

Compressive Strength is just one of many tests performed on brick but it is good to know that the brick you are using today far exceeds ASTM requirements.