Words: Cassandra Stern

Photos: Quick Headers, SPEC MIX

Merriam-Webster defines efficiency as “achieving maximum productivity with minimum wasted effort or expense,” but how do you define it? Recently MASONRY Magazine sat down with Quick Headers and SPEC MIX for an in-depth look at what efficiency means to them and what it looks like in their respective industry segments. One essential aspect of these discussions focused on the return on investment regarding equipment on the jobsite- a common issue among mason contracting companies with a variety of budgets.

Internet search engines opened up easier access to more efficient operations via price comparison tools, scheduling and accounting software, and other technological innovations. Before this, masonry contracting professionals were restricted to manual price comparison research when making decisions regarding company investments that could significantly impact company profitability down the line. Today, with the click of a few buttons and keys, mason contractor professionals responsible for upgrading or replacing equipment can skip the trade shows and appointments while the information needed to make a purchasing decision lies at their fingertips.

Time is Money

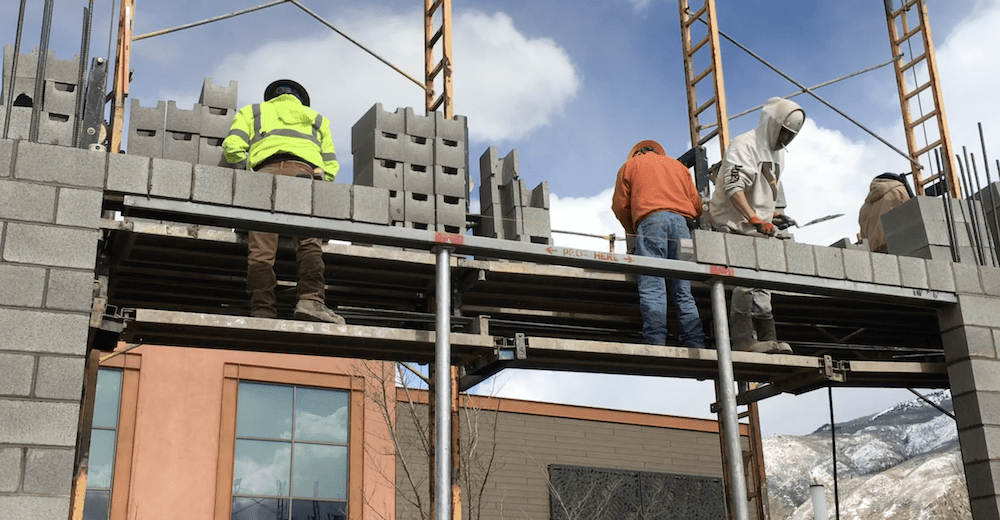

Masonry professionals are in charge of pushing the timeline of the jobsite along during the duration of any project, and inefficiencies can appear throughout the process, like cracks in a wall. One particular aspect that can be closely examined when looking to improve efficiency on the job site is equipment that supports work processes rather than performs them.

Are your masons outperforming the capabilities of your available mortar mixers? Is your scaffolding old, outdated, and takes twice as long as newer models do to set up? Too often, mason contracting company owners and operators are blinded by larger purchases to focus on the smaller ones (which can have a potentially more significant impact.) For example, a telehandler that can go higher than your current one may allow your contracting company to accept bids for more extensive and taller projects, but will your existing mortar mixer meet the increased demand?

Those who choose to invest in their company efficiencies by renting rather than owning these types of equipment have to ask themselves a different set of questions, but with a similar end-goal in mind: improvement. Rental costs tend to be more project-specific, focusing on the short-term investment to complete the project rather than considerations of lifespan and maintenance.

Small Changes Can Make Big Improvements

When renting, masonry professionals focus more on how equipment can improve time spent on specific tasks rather than the cost per individual job. That being said however, further analysis on whether or not to own or rent your own equipment should be factored into the consideration of a subsequent ‘breakeven point’ discussion. “Besides the safety and environmental features of Quick Headers, a primary thinking behind our product has been the return-on-investment aspect,” explains Judy Kelly of Quick Headers, LLC, owner of the temporary, removable beam support system used when setting concrete masonry blocks, CMU, over a window or door openings, eliminating the need for wood bucks. Tools like Quick Headers are an invaluable tool for masons that can help save time and money in a relatively short period. This is crucial when considering potential saved time and improved workflow to determine the return on investment.

The key is to identify situations that can benefit from improved efficiencies and then determine the best way to implement those changes using the solution with the greatest return on investment (ROI). “One easily overlooked and common example is when masons must come off the scaffolding to perform a non-masonry task such as building a wood buck,” Judy explains. “Studies show that considerable losses are incurred when transitioning between tasks, resulting in some of the greatest losses of productivity in the workplace.”

Once the problem is identified, as this one clearly is, it can easily be remedied after researching the appropriate breakeven point and return on investment once the proper tool is identified. “When you’re talking about Quick Headers breakeven points specifically,” Judy explains, “if a contractor or an end-user who owns their own equipment were to compare a 5’4” opening using the true costs of building a 5’4”wood buck vs. using a 5-foot Quick Header, they would find that they would break even after only three uses of the Quick Header.”

In this example, the Quick Headers’ breakeven point is less than two months of consistent use, but this varies greatly between different products and equipment. The breakeven point occurs when the amount invested in a purchase has paid for itself in services performed. For example, the financial breakeven point for a reusable water bottle that costs $20 would be when the purchaser consumed the equivalent amount of single-use bottles. For mason contracting company owners and operations, this extends to improved efficiencies in time saved during routine work processes, like an investment in a mortar mixer or scaffolding equipment that is easier and faster to use.

Once the breakeven point has been determined, the return on investment can be more thoroughly explored. Identifying an issue on the job site with the current wood buck system and investing in a replacement like Quick Headers will quickly demonstrate the value of the investment, which will potentially be reflected not only in the quality of the work produced but also in the timeliness in which it is completed. Using the same five-foot header from the previous example, Judy further explains that “a mason doesn’t have to build a wood buck anymore, therefore his annual return on investment would be over an unheard of 1,000% with consistent use and that really adds to the bottom line over the life of the Quick Header.”

Quick Headers are just one example of the invaluable tools for masons that helps to save time and money in an extremely short time frame. More importantly, this example shows how investing in innovation provides a unique opportunity to prove how impactful a simple change in thinking can be on both the break-even and return-on-investment. This is essential when considering potential saved time and money with improved workflow to determine the return on investment.

Smart Planning Means Smarter Spending

Jesse Steger, Masonry Foreman of C.D. Construction, Inc. in Fond du Lac, Wisconsin, describes another factor that returns on investment can have when implementing improvements in job site efficiency through his experience on a recent project. Says Steger, “we specifically purchased a D2W Workhorse mixer for the Sellery Hall project we’re on at the University of Wisconsin, and it’s already paid for itself.” He explains further that “the fact that it’s an electric, dustless, indoor/outdoor system that we can move from wall to wall on each of the Hall’s 11 floors to mix mortar and grout, without wasting time and material, is a huge advantage.”

Steger explains that he identified the specific need for a particular project, which he then considered when investing in the appropriate equipment before construction. His careful choice of materials and equipment ultimately plays a prominent role in the successful project outcome because of a combination of research, consultation, and planning before execution. When approaching a project like this one, start with a generous estimate of how much work product will be needed per day to complete the project under budget and time constraints.

In this example, the SPEC MIX DW2 Workhorse mixer may not have been the least expensive option for the project, but its output and performance overvalued any other competitor. According to the SPEC MIX website, “the design and performance of the D2W Workhorse is the contractor solution for increased profitability. It allows you the opportunity to mix material within feet of your craftsmen—with minimal setup, labor and zero waste—while continuously producing a high-quality mix.” Mason contracting company owners and operations managers looking to rent or purchase jobsite specific equipment mixers like the DW2 Workhorse would be remiss if they failed to consider the time-saving implications of their return on investment. By investing an appropriate initial amount of both time and resources before purchase, planning can, in turn, pay dividends in returns.

Investing the Efficient Way

The cheapest option may not always be the best option. For example, those inexpensive boots might seem like an attractive option, but the lower quality materials can lead to a faster breakdown, less support, and other unwanted problems. In situations like these, the cost of improving efficiencies (more supportive boots) can lead to a much greater return on investment (improved work performance). On a larger scale, corporate investments into job site equipment can have far-reaching implications that must be carefully considered — and research into the potential return on investment can be of grave importance when making a final decision. Factors such as time, workflow, and production rate are just components that help reveal a purchasing decision to be a success or failure. Consider the many methods of making an informed decision the next time you rent or buy, and you may see the difference in your bottom line.

Thank you to Judy Kelly of Quick Headers and Brian Carney of SPEC MIX for their contributions to this article. To learn more about their products and services, visit http://www.quickheaders.com/ or https://www.specmix.com/, respectively, or contact MASONRY Magazine with questions.