Words: Vanessa Salvia

Photos: FBR

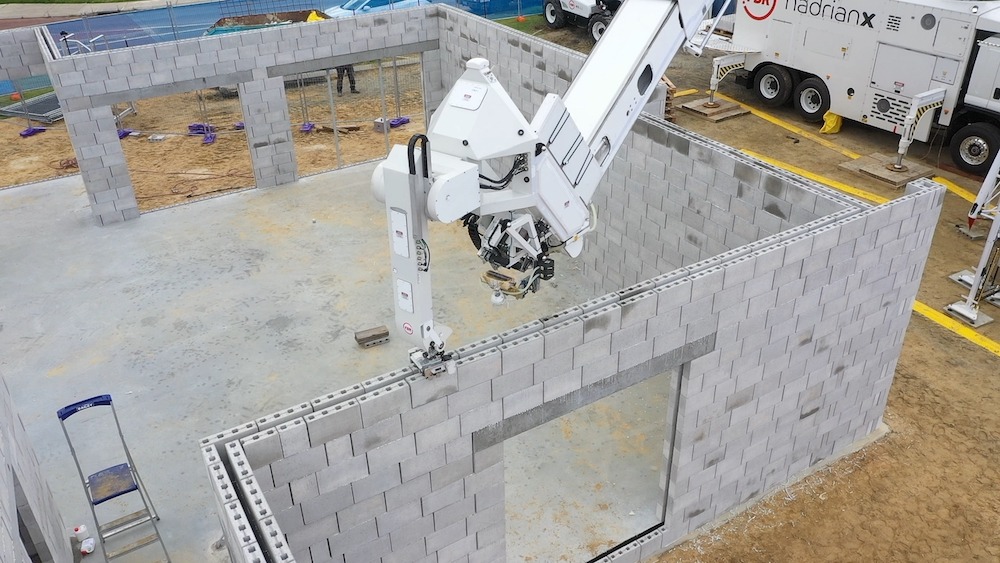

Two years ago, FBR was poised to revolutionize outdoor construction robots with the introduction of its Hadrian X. That time has now come.

When the assembly of the Hadrian X was completed and FBR was beginning testing and commissioning to ensure safe and orderly operation, the global pandemic hit. Fortunately, FBR’s isolated geographic location in Perth, Western Australia, meant that COVID-19 lockdowns didn’t last long, allowing FBR to push ahead with its first build-outs in the community using the Hadrian X. FBR has now built a display home and a commercial community center in the residential suburbs in Western Australia for building clients.

On Saturday, July 11, 2020, the Hadrian X finished building the structural walls of its first display home in Dayton, Western Australia. It took only one and a half days of preparation — building commenced on the morning of July 8, and Hadrian X completed the structure in only three and a half standard shifts using concrete masonry blocks (CMUs). The Hadrian is capable of using both clay and CMUs. On its second build, a low-rise commercial center in Perth, Australia, Hadrian constructed both the internal and external leaf of a double brick 2-inch (50 mm) cavity wall with slab step-down and a render finish.

With most industries, humans do the same or very similar type of work for decades, if not centuries. Masonry is not so different. Eventually, technology advances or changes to the point that it’s no longer feasible or just doesn’t make sense to have humans continue to do the work the same way. Yes, there are always humans who know how to lay bricks to construct a building, but a machine like the Hadrian X can overcome obstacles that humans can’t.

Mexico and Australia have a chronic shortage of safe and affordable housing. Builders are hoping the Hadrian X can build homes faster than humans can, and make a dent in that area. In the United States, our challenges are labor shortages and an aging workforce. FBR believes that commercial adoption of the Hadrian X means humans can avoid the physical toll that some of the hard work takes on their bodies, and get work done faster, more safely, and more affordably. Experts are predicting fewer masons in the years ahead, and machines like the Hadrian will be necessary to close that gap.

The Hadrian X can be imaged as a large Pez dispenser attached to a cab-over-engine truck. The truck is just a transportation method, essentially, so that it can be easily moved from site to site, but the dispenser can also be mounted onto other bases such as tracks, barges, boats, or cranes. Instead of dispensing candy pellets, the Hadrian X takes in pallets of blocks from its back. From there, it’s a beautiful ballet of speed and precision which no human can match. The machine automatically dehacks, cuts, or routs the blocks as needed and transfers them to the boom, where an arm lays them with the utmost precision. The Hadrian X places up to 1,000 standard brick equivalents per hour via a 100-foot (30-meter) boom. Its placement margin of error is less than one millimeter. The Hadrian can also use a range of different size brick or block products.

There have been other inventions that aimed to achieve similar results. What makes Hadrian different from its predecessors, though, is an intelligent control system guiding the machine, along with a feature known as Dynamic Stabilisation Technology. This offers countermeasures to keep the work going despite strong winds, vibration, temperature variations, or other conditions that would impact performance. Prior to these advances, robotics like this had potential only for indoor use.

On the display home build site, the Hadrian took only 90 minutes to get ready to work. The home was built using blocks that were 15.4 inches long (390 mm) and 9.1 inches high (230 mm). The blocks were delivered earlier that day and stacked to one side, instead of being spread out across the slab and build site as is the usual method. Hadrian is capable of laying blocks 19.7 inches long (500 mm) long and 9.8 inches high (250 mm).

“As the Hadrian builds the entire structure course by course from the one position, the structure is measured in courses, not walls,” explains Steve Pierz, Chief Innovation Officer of FBR. “The Hadrian hit a laying speed of nearly 200 blocks per hour, which is the equivalent of about 16 square meters of wall per hour.”

That’s not even a final number. An upgrade currently underway on the machine will see that increase to more than 300 blocks per hour or more than 25 square meters of wall per hour.

Masons weren’t sent home on this project. Hadrian built the internal walls and the internal leaf of the external walls. Masons applied clay face brick to three sides, and then a rendered front with some cosmetic stonework. It took a team of three masons three days to complete the face brickwork, as opposed to two to three weeks under traditional methods, says Pierz.

“The display home used standard off-the-shelf clay face bricks for the cosmetic finish,” says Pierz. “In our proposed markets, there are a multitude of different finishes that architects or builders can use, from face brick, renders, and stone finish to cosmetic panels and brick slips. This is only limited by imagination.”

The display home will be opened to the public and to current and potential suppliers and partners to demonstrate and promote the feasibility of this technology. In addition to the display home, Hadrian also built its first commercial structure, which will be finished with an acrylic render. On that project, the robot and masonry were working at the same time.

“I think this project was a great demonstration of how both the robot and humans can work together and do what they need to do and not have any issues,” Pierz says. “It was a very successful build, over about 22 hours, averaging 180 blocks per hour.”

On September 9, Hadrian completed the structural walls of a commercial and community center in Byford, Western Australia. The project was completed as the third and final stage of FBR’s Building Pilot Program Agreement with Archistruct Builders & Designers. On this build, Hadrian contended with hail, high winds, and heavy rain yet still achieved an average laying speed during the uptime of approximately 174 blocks per hour, or approximately 800 standard brick equivalents per hour, bettering the results achieved at the display home. The completed structure is 15 courses high, including slab step-down, or approximately one and a half stories, with brick ties manually installed. Hadrian used 4,075 for a vertical surface area of 3,885 square feet (361 square meters)

FBR has also been working in a Pilot Program with Mexican company GP Vivienda to develop an affordable housing solution for Mexico. FBR constructed four Mexican-style two-bedroom, one-bathroom house structures using the Hadrian X at FBR’s premises, with each structure taking less than one standard shift on average to complete. FBR also demonstrated the two-story capability of the Hadrian X, building a Mexican style double-story home in testing at its premises. The next steps are to continue improving and establish a North American Wall as a Service operating entity and market entry for the Hadrian X in North America.

“We will be coming to North America soon and we are currently talking with leading residential home builders and gaining commitment to building homes,” says Pierz. “We are happy to talk with and work with any residential/light commercial builder interested in the Hadrian that is willing and meets FBR requirements for the number of structures and square meters of wall.”

There are many global markets that are perfect for the Hadrian. Europe, the UK, the USA, the Middle East, and Asia all use blocks for construction, and all are facing severe skilled labor shortages. The COVID situation has disrupted plans, but at the same time, it has given FBR a great opportunity to improve. They have increased Hadrian’s lay rate significantly and re-engineered different parts of the machine to make it more robust.

“The COVID situation has only seen this problem multiply, and the demand for Hadrian has far exceeded our expectations for this stage of our journey,” says Pierz. “We will continue to trial and test block products from around the world under pilot programs in the months ahead, with global partners and interested companies in preparation for our arrival into these markets as soon as global travel permits.”

In the meantime, Australia’s large masonry construction market is perfect for the Hadrian to hone itself, and there will soon be more than one Hadrian now that its suitability has been proven.

Watch a video of the completion of the display home: https://www.fbr.com.au/view/news-articles/20200713012933

The videos from the first commercial structure build in Byford, Australia, can all be viewed here:

Video of the building of two side-by-side demonstration homes in Australia: