Words: Guy Erickson, Business Manager and Sales Manager at Trimble, Structures Division

Photos: Trimble

One of the greatest challenges facing the concrete construction industry is a lack of quality, coordinated, and timely information. Today, Building Information Modeling for Masonry (BIM-M) software can help contractors who plan and place concrete overcome this challenge.

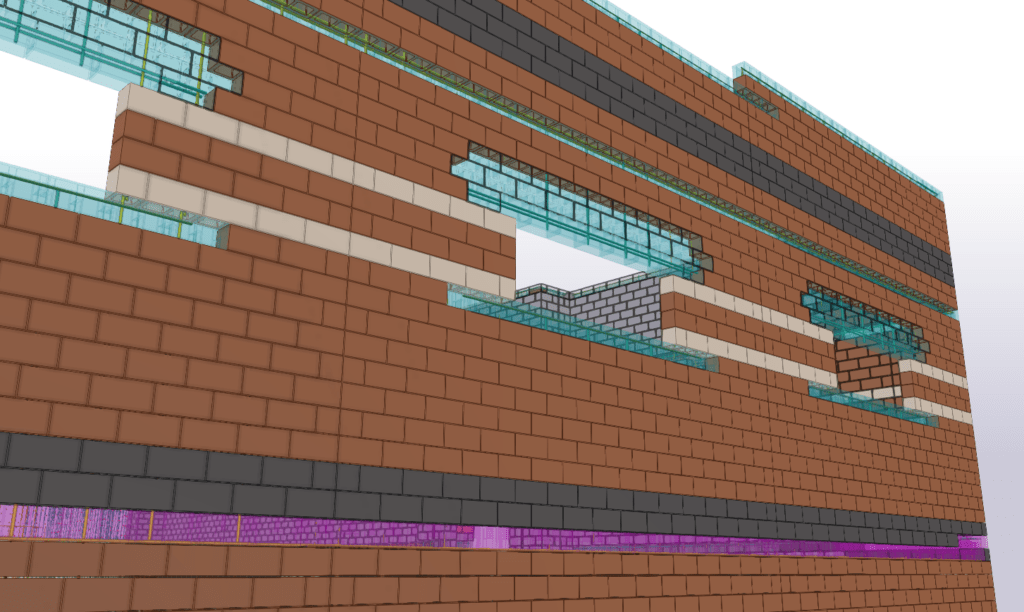

With the right BIM-M software, it’s possible to create data-rich constructible models that can be leveraged throughout the preconstruction and construction project phases. Tekla Structures, for example, is a purpose-built tool, specifically engineered for the construction industry, with an emphasis on constructability. A variety of disciplines in the concrete industry including mason contractors, self-perform general contractors, rebar detailers, and formwork manufacturers, rely on Tekla Structures. Collaboration platforms, such as Trimble Connect, make it possible to share 3D models and leverage the data within them throughout the design and construction process across project stakeholders, from the office to the field.

Common Uses of BIM-M

With BIM-M, 3D visualization, accurate quantification, and reporting can all be accomplished with little effort outside of creating and orienting the objects. Contractors using BIM-M have the option to import an Industry Foundation Class (IFC) reference file into the software or build the model from an imported 2D PDF or DWG file. Most contractors using BIM-M prefer the latter, and build the constructible model from scratch using an imported 2D file. This gives the contractor the opportunity to create a constructible BIM-M model that is so accurate it can be constructed in the field. This approach offers the contractor better planning for delivering projects on time and on budget. It also helps identify potential delays such as project changes, staging logistics, scheduling, cost, and trade coordination.

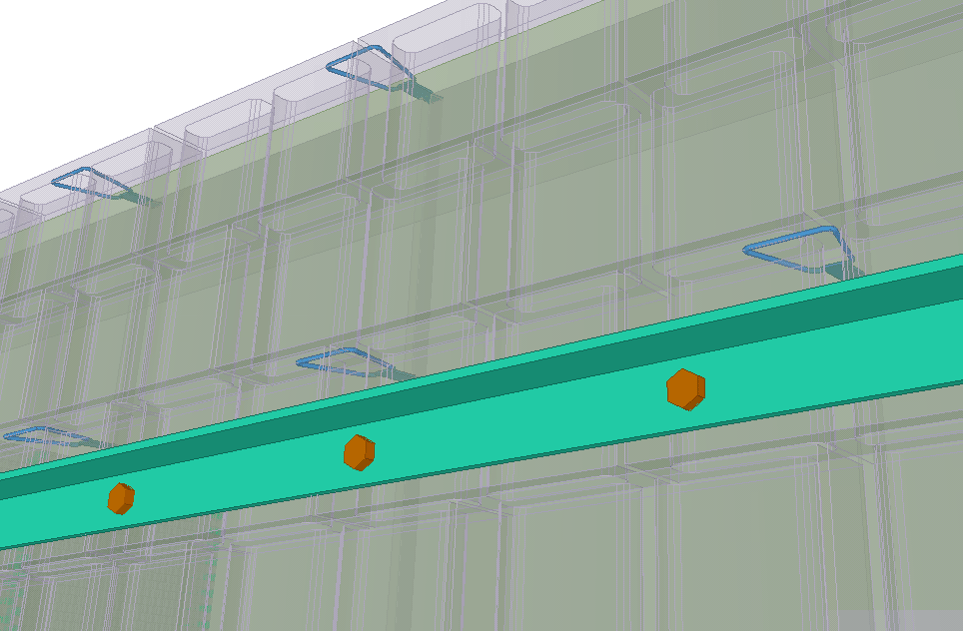

BIM-M can help increase production in a variety of ways, including project layout and survey, planning and management of work, as well as determining site logistics. When it comes to project layout, data point creation is expedited using filters to apply points on model geometry quickly and accurately. Robotic Total Stations (RTS) allow workers to import data points created in the model to a hand-held tablet device in the field.

That data is then relayed to the RTS that provides accurate setting out from the information model using its laser measuring system to a tolerance of 2mm. This technology corrects for points on uneven surfaces and locates wall penetrations. Any variations to the model data due to changing conditions onsite can be logged and fed-back as as-built data to the project team. Even just from an efficiency point of view, this enables one person to set out five times as many points as a two-person team using manual methods.

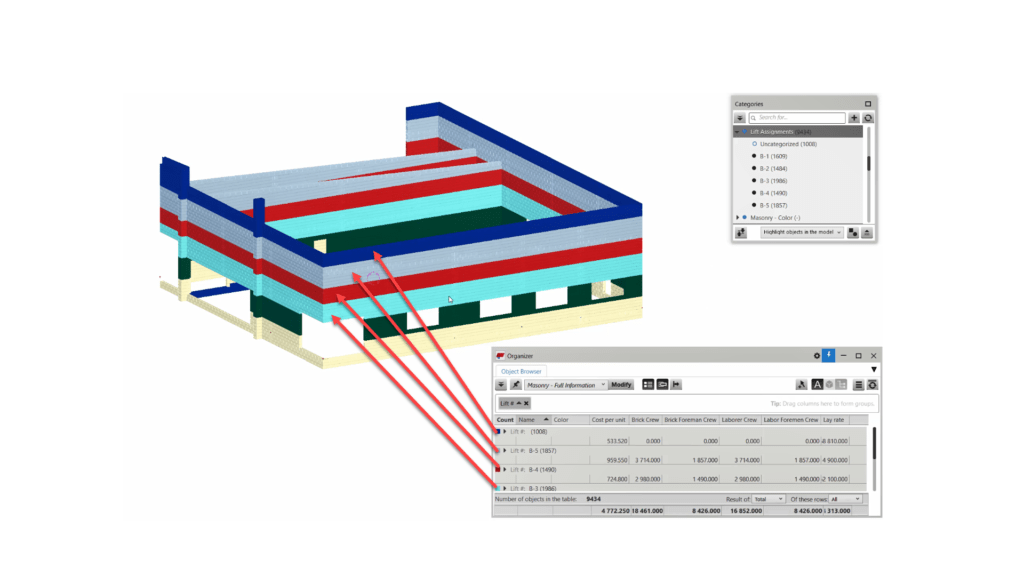

Planning and management of the work to be completed is the main benefit of BIM-M. Project status and reporting become more accurate and decisions can be made faster and based on reliable data. For example:

- Course and seam locations can be identified and communicated to field crews.

- Creating, modifying, and identifying potential configuration oversights in rebar design becomes easier.

- Quantification and reporting changes are tracked and updated in real-time.

- Shop and field drawings are adjusted and created without long delays.

- BIM-M includes the latest revisions so a contractor can feel confident they are building from the most recent and up-to-date version.

BIM-M also provides opportunities to improve site logistics. For example, scaffolding systems can be modeled and planned in advance. This enables a better understanding of quantity and inventory requirements. Models can also be used for coordination of laydown areas for more efficient material storage in relation to work sequence. And, speaking of sequencing, work tasks can be assigned to model objects to better plan and visualize labor needs, such as work crew assignment and staggering of installation. Models can also be used to quickly create bills of materials with reporting and field use installation documentation with drawings.

Innovative Uses for BIM-M

BIM-M not only has the potential to capitalize on the common uses of BIM but also forge its own unique applications, all of which leverage constructible data within the model to propel the construction process forward. With BIM-M, information can be shared in real-time, provide clear and effective communication on job requirements and configurations, and deliver up-to-the-minute status updates from the field to the office. Constructible BIM-M can also be used for real-time tracking of projects and help identify issues in a controlled environment before construction begins. Clash detection and conflict resolution between material and trades can be identified from models for quick planning of resolutions and delivery of documentation to the field. This saves time and allows the user to plan for project changes.

BIM-M can be shared with all project stakeholders, increasing productivity, collaboration and efficiency between other disciplines, project management and field crews. With this level of coordination, which is only available using BIM-M, quantities can be checked, productivity measured and live project status shared. As a result, interaction between trades and vendors are streamlined with the model. Potential project changes and requests for information can be identified and easily communicated with BIM-M.

Integration with Other Software

BIM-M ‘s integration with other software systems allows for interoperability and coordination. These systems and tools are essential for sharing information with internal programs and project stakeholders throughout the project lifecycle. IFC, for example, is a common file type for sharing BIM-M models.

Integration happens in many areas, such as quantity take-off, estimating, scheduling, site planning, project layout, QA/QC, erection, and project turnover, to name a few. Software integrations are very common among today’s larger software providers and many file formats are used, including IFC, PDF, DWG, text, xml, cnx, dgn, and tfl.

In addition, some software providers have collaboration platforms that make it possible to access, share, review and comment on cloud-enabled, model-based projects and easily share models, drawings and documents with other project participants from anywhere, at any time, regardless of which solution you use.

Misconceptions of BIM-M

Perceptions of emerging technologies and new workflows often misrepresent reality. When opportunities for business improvement, such as BIM-M, come along it is easy to form misconceptions based on limited or incomplete information. For example, “BIM-M is expensive.” In reality, BIM-M is fairly inexpensive and quickly delivers a return on investment (ROI). Another misconception is that previous CAD or 3D experience is needed to utilize BIM-M. Previous experience is helpful, but not required. Anyone with a building background, who can read plans and has desire to learn, can take advantage of BIM-M. In fact it’s important to note that real world industry experience is just as valuable as any CAD or 3D background for BIM-M. They truly form two sides of the same coin.

In addition to these points, people often think that all the features of BIM-M software need to be used right away. In fact, the opposite is true. It’s better to identify an information workflow for your company and reach pre-defined milestones. From there you can continually incorporate additional features and grow organically as time goes on.

Remember that there is no “easy button.” BIM-M won’t automate everything with a push of a button. In reality, BIM-M will automate tedious tasks within a designer’s workflow but input from users greatly increases efficiency and output from the model.

Specialized Training

If you’re new to BIM-M, take an iterative approach to training and implementation. Start with no more than three short-term goals. As your workflows progress, introduce longer-term goals. Work with your software provider to identify immediate pain points in your business model. These will be the low hanging fruit for increasing productivity.

Most software vendors offer training. As with any new software, there is always a learning curve. Training and implementation programs should be accompanied by a specific plan that meets your company’s goals, timeframe and bandwidth. In many cases, industry knowledge, experience and best practices will help you adapt to BIM-M software.

A BIM-M solution that is purpose built for masonry will be easier to learn. You’ll spend less time trying to customize the software to meet your needs. In addition, seek a BIM-M solution that offers online content. Manufacturer information and specifications enhance model detail, ultimately accelerating model authoring for productivity benefits.

When it comes to training, classroom settings offer faster learning experiences in less time. However, in the wake of the COVID-19 pandemic, the opportunities in person training are limited. Therefore, eLearning is essential but also presents challenges. eLearning requires candidates to shut down their daily work duties and phone calls to focus on the training. Regardless of how you learn the software, make sure your BIM-M provider focuses their efforts and time on ensuring a smooth implementation.

The Cost of BIM-M

The construction industry has evolved and BIM-M now has a low cost investment point. ROI is achieved fairly quickly through the increase in production and reduction in project errors that reputable BIM-M software and constructible models can deliver with proper planning and implementation.

With the increase in BIM adoption, we’ve seen a shift from traditional BIM users. The early BIM adoptions were engineers, architects and designers. Many companies today have BIM managers, Virtual Design and Construction departments and other BIM-related roles. With these changes, labor costs and availability can be a concern.

There are companies that specialize in providing modeling services, BIM execution plans, schedule optimization and other BIM services. It’s important to understand cost, goals, project requirements, contract liability and deliverables when considering a consultant. Trimble also offers these services during software implementation or as a standalone service.

Conclusion

It’s easy to see the positive impact of integrating BIM-M into your business. The time and cost savings you’ll achieve in planning, management and logistics alone are worth the investment. If those are not your pain points, BIM-M still has plenty to offer in drawing creation, instant reporting, field and project stakeholder coordination and resolving construction issues before they reach the field.

The bottom line is that BIM-M reduces redundant work and increases collaboration by making it possible to visualize, manage, edit and share constructible 3D visual representations of a project throughout its lifecycle. The question is, where does that leave you?