Words: Dan Kamys, MASONRY Editorial Director

Photos: Interstate Brick

Editor’s Note: This article is the second part of our October 2019 cover story. In that feature, we gave an outline of structural brick and explained the newer question of resiliency as it pertained to ballistics. Additionally, the piece provided detailed information on how Interstate went about developing a strict set of testing protocols based on other standards from Underwriter’s Laboratories, the National Institute of Justice, State Department, and ASTM. If you haven’t had the opportunity to read the first part of our series, please go to masonrymagazine.com and search for the term ballistics.

If you read the first part of our series, you’ll recall that the protocol involved gradually increasing the caliber of ammunition used to test masonry. However, the structural brick was performing well— so well, in fact, that the testing had to be paused for safety reasons.

“The higher [energy] ballistics… were deflecting off the wall and ricocheting back into the field of play,” Don Sackett, General Sales Manager at Interstate Brick explained. In the interest of safety, “we terminated testing at that point so that we could build a stronger armored barrier to protect the shooter and also remove spectators from the field.”

The Testing, Continued

Steven Judd, Technical Director at Interstate Brick and sister company H.C. Muddox, sat down with the MASONRY team to outline the second set of tests.

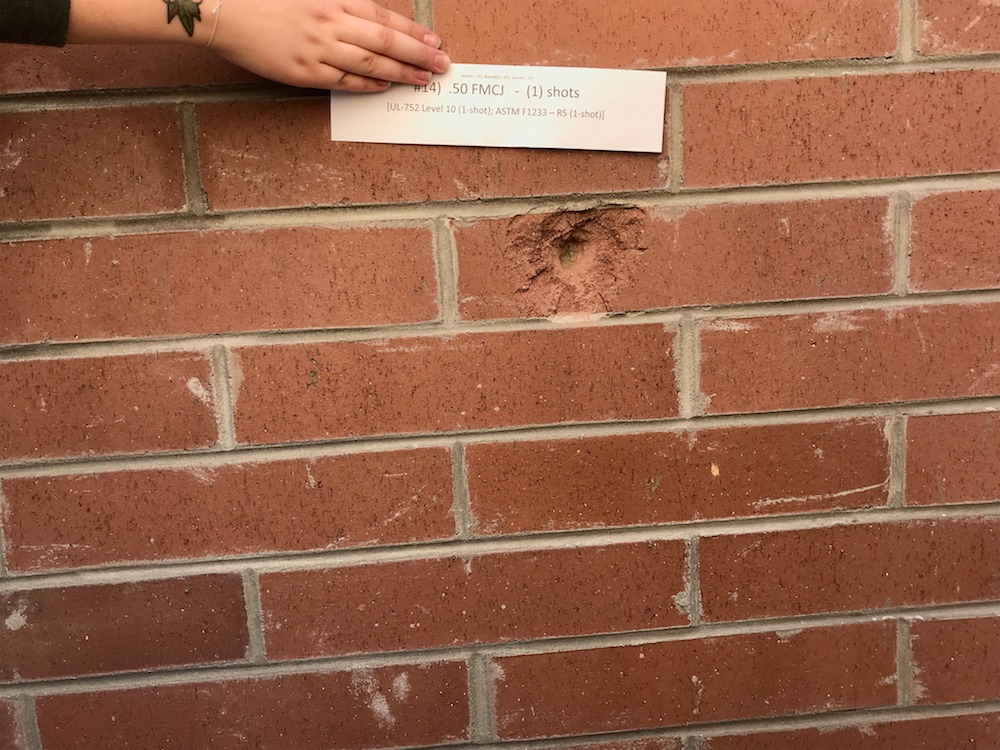

“We tested high-energy ballistics, which included the .38 Super and .44 Magnum handguns and higher-caliber rifles: .308 Winchester, .30-06 that included armor-piercing rounds, .223, which is an AK-47 type rifle, and a .50 caliber sniper rifles. All of our test protocols passed [for the structural brick walls] except for the .50 caliber, which did pass completely through the brick veneer wall assemblies we had. It was a very successful test.”

All of the test protocols passed for the reinforced and grouted structural ballistic brick walls passed the test protocols, even the .50 caliber at 15 feet muzzle to face of wall. “It was a very successful test,” Judd said.

“I thought the veneer walls would have failed more of the ballistics tests than they did, [but] they only failed the .50 caliber. I’m not particularly surprised by the reinforced and grouted structural masonry walls because of the indications we received from our preliminary testing, which was also very positive.”

In terms of what was done differently to protect those participating better and observing the test, Steven explained that the protection devices were made thicker, and a steel barrier was added. Additionally, a remote gun mount and remote trigger mechanism were used, so the individuals shooting the rifles were actually protected behind a plate steel barrier. It was an extra precautionary measure to make sure we were as safe as possible.”

As for what comes next, Steven explains that there’s no further testing planned, but that could change depending on the needs of the design community.

“Let’s say [a customer] wants to build an embassy somewhere, and they want to have some additional testing done. That would be a good reason for us to then engage in additional testing. What we’ve done should satisfy, to a large degree, anybody’s need for information about the ballistics resistance of the walls. We combined and blended four standard national protocols to try and cover all the weaponry that is used.”

The brick veneer walls, which were tested separately from the grouted and reinforced structural brick wall assemblies, also outperformed Judd’s expectations. “I thought the veneer walls would have failed more of the ballistics tests than they did, [but] they only failed the .50 caliber, which did pass completely through the brick veneer wall assembly.

It should be noted that the results of the testing are not necessarily transferable to other brick manufacturer’s products because the properties of the clay from which the brick are produced are unique to Interstate Brick. Weaker brick, which is still in compliance with ASTM C216 and C256 strength requirements may not perform the same for ballistic resistance.

What’s Next?

The next steps for Interstate involve getting this information into the hands of as many as possible.

“What we plan to do next is to put together some sort of a coordinated marketing effort or make this information available to designers and owners and builders for situations where the ballistics resistance or resilience is a critical part of the design.” Ryan Riley, Marketing Manager of Basalite Building Products, LLC, parent company of Interstate Brick, elaborates.

“We want, as best we can, to let the design community and architectural community [know] the resiliency [of the structural walls] and ballistics. To our knowledge, we’re the only brick manufacturer that has both a UL fire rating, a projectile or storm shelter storm certification rating and now a ballistics rating. We have gone the extra mile to make sure that our quality and the ability to depend on our product to withstand certain elements are going to be there and that we’ve tested and made sure of that.

During our team’s conversation with Steven, he brought some interesting points regarding what resiliency means and how there may be opportunities to expand the use of structural masonry.

“The reason why we blended the four different testing protocols was to try and cover as many potential use cases as we could. The National Institute of Justice deals with courtrooms, where people sometimes express themselves very poorly when the verdict comes down from the bench. I don’t know if you’re aware of this, but most judicial benches have a steel plate reinforcement in front of them so the judge can duck down behind those if something happens. They have their own safe means of egress. That’s why they always come through a different door than everybody else. Over and above that, [we’re considering] protection of anybody in adjacent rooms, spaces and corridors as one of the potential uses for this brick.”

“At a typical bank, drive-up teller window’s glazing is ballistic rated, but what’s the wall below the window? Well, if you don’t add some other level of protection, that’s the weak point for any ballistic entry. So if you use the reinforced structural brick for that, then you have a consistent level of resistance without having to do anything special.”

The Department of Defense protocol was followed for the potential of building embassies out of the product. The DOD additionally builds American schools in foreign military installations, which could be another use.

“ASTM and UL have their own [protocols] as well, and those can be applied to many different kinds of private and commercial buildings. So, we were trying to cover as many bases as possible. If the need arose and somebody said, ‘we’re thinking of building a police station, what level of ballistics protection do your walls provide,’ we have answers now. Previously, we just had sort of no hard data. Now we do.”

Final Thoughts

It should be noted that the structural ballistic brick that was used in this test is a special run brick. The units were modified in a proprietary manner to enhance the resiliency of them. The reason this was done is because of Interstate’s commitment to safety. Previous tests involving fire resistance and FEMA’s tornado projectile tests helped lead up to the need for a new unit.

“We want people to be able to build secure environments using our products safely to increase the resiliency of individuals, families, and communities. If you build a grocery store that gets wiped out in a tornado, where is that community supposed to go and get their food? If the grocery store is built to FEMA standards, then it’s still there, and it increases your ability to bounce back after a natural disaster because you can go get supplies, and those facilities remain intact.”

Whether it be weather, seismic, or ballistics-related resiliency, it’s clear that the choice should be masonry. It’s also worth noting that Interstate Brick has chosen to take on the expense and workload of developing this testing effort as a result of the request from the design community. While they could have continued to say, “it will hold up,” they developed a rigorous testing protocol for their product.

We at the MCAA look forward to continuing to collaborate with Interstate Brick on the future of their commitment to safety and resiliency.

INTERSTATE ACKNOWLEDGEMENTS

AK Masonry (Masons and equipment)

Child Masonry (Masons and equipment)

IMS Masonry (Masons and equipment)

Quikcrete (Mortar and Grout)

Clydeco Building Products (Rebar)

FRITZ-PAK (Admixtures)

Sika Corporation (Admixtures)

CTS Cement Manufacturing (Cement additive)

Salt Lake City Police Mutual Aid Association (Gun range)

Unified Police Department (Planning, Advice, and Weapons)

Steve Bigelow (Rifle)

Stuart Wallin (Handgun)

Interstate Brick employees