My wall has a crack – should I be concerned?

Well, it depends on its nature because not all cracks are created equal. Cracking is visually alarming, but often there is very little effect on structural stability. Before we discuss the most common causes of cracking in masonry, we need to understand why cracks are so important. A crack is the most common evidence of masonry performance failure and an indication that the building could potentially have structural issues. Cracks and open joints are considered a primary source of water infiltration in masonry walls above grade, and their presence may lead to moisture penetration issues, such as corrosion, stains, efflorescence, etc. If you notice a crack in your wall, don’t ignore it: talk to your engineer and ask for an evaluation. Remember, all cracks must be examined.

More often than not, the primary cause of cracking in masonry buildings falls into one of the following three categories: movements, overloading, and material failure. It is not a secret that cracks are often caused, in different ways, by movements. In this case, the presence of cracks is an indication that the building has, at some time, been subjected to an imposed movement from the external environment, such as ground movement or thermal movement. Ground movements are often caused by changes in moisture content of the soil around the perimeter of the foundation, poorly compacted fill, adjacent excavations, tree roots, etc.

Thermal movements are caused by the response of a given material to thermal fluctuations over time. When masonry is exposed to increasing temperatures – think about a south-facing wall getting warmer during the day – it expands. On the other hand, exposure to decreasing temperatures will result in contraction. When exterior masonry is exposed to hot-cold temperature cycles over time, it expands and contracts. Construction materials can also move on their own due to their physical properties. Shrinkage, which in simple words is the contraction over time of cement-based products, affects concrete masonry blocks, mortar, and grout. On the other hand, clay brick expands irreversibly over time.

Cracking may also result from differential movement at the interface between dissimilar materials, such as at a band of clay brick in a concrete masonry façade. Since thermal movements and shrinkage cannot be fully prevented from happening in masonry buildings, designers try to accommodate movements and control cracking by using control joints, expansion joints, and joint reinforcement.

When structural elements are subjected to more load than they can handle, they will crack due to overloading. These cracks should be taken very seriously as they can result in structural instability and collapse if the overloading issue is not addressed. Have an engineer evaluate your masonry crack to determine if it is caused by structural overload.

Figure 2. Cracks in masonry parapet due to differential movement between clay brick, which expands over time, and concrete, which experiences shrinkage over time.

Corrosion of embedded metal in masonry, such as wall ties, joint reinforcement, structural steel, lintels, etc., can also cause cracks in surrounding masonry. As the metal is exposed to moisture, the oxidation process is activated, forcing the material to expand. When severe corrosion occurs, the oxidized metal can expand up to 7 to 10 times its original volume and produce intense bursting forces in the surrounding masonry, which will eventually crack and spall.

It is very difficult to tell the cause of a crack just by looking at it. Given the complexity of the problem and the lack of standardized guidelines, crack diagnostics may be a challenging task. At the very least, the investigation should consist of two phases: documentation and interpretation. A good rule of thumb is to gather as much information as you can to help identify the cause. At a minimum, crack location, pattern (horizontal, vertical, diagonal, etc.), and dimensions (length, width, and depth) should be recorded using photographs and sketches. Although difficult in most cases, an attempt should be made to estimate the age of a crack.

In general, it is easier to identify older cracks, and common signs to look for are: cracks coated with paint; presence of dirt and/or biological growth in the crack; old repairs. On the other hand, clean edges are an indication a more recent crack. If you are lucky, a building owner has paid enough attention over the years to tell you about the some of the crack history. And if you are really lucky, he also recorded on the wall the exact date the crack appeared.

Most importantly, the investigation should determine whether a crack is active or dormant. Why is this important? An active crack is an indication that the underlying cause of masonry performance failure is still at work; this cause needs to be treated before the crack can be repaired.

Figure 3. What a lucky day: it does not happen very often to find dates recorded adjacent to an existing crack. In this case, the vertical crack grew only one course from September 1959 to February 1961 before stopping: this crack is certainly dormant!

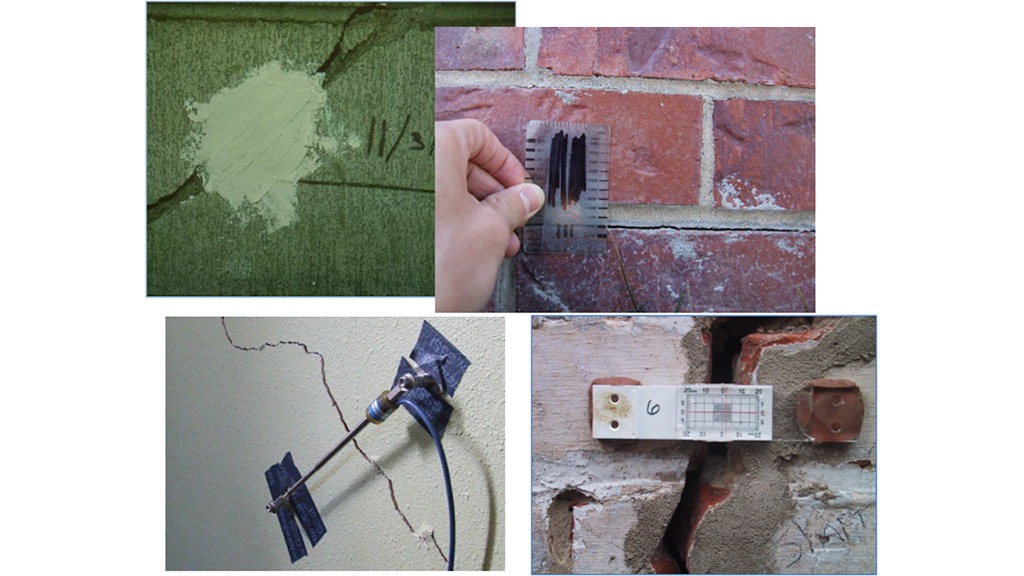

There are several methods that can be used to tell if a crack is active or dormant. The simplest one is to patch a small area across the crack with non-shrink plaster or mortar and inspect the patch at regular intervals to see if it has cracked. Another relatively inexpensive approach is to monitor crack movements by measuring the crack width using a hand-held crack comparator. By comparing measurements taken over time, this method also provides useful information about the basic direction of the crack movement, i.e. opening or closing.

Cracks can also be monitored by installing a two-piece crack monitor, which features a red cross over a calibrated grid system: the horizontal and vertical crack movements become clear as the red cross slides over the grid system. For a more advanced monitoring, electronic crack gauges connected to a data logger provide continuous recordings of cracks movement. The system can also be coupled with a weather station to record environmental variables, such as temperature and wind speed. While this approach is more complex and expensive than other methods, it provides more accurate results and can potentially link the crack movement to thermal or wind loads.

Figure 4. Monitoring cracks. Clockwise from top-left: plaster patch; hand-held crack comparator; two-piece crack monitor; electronic gage.

The second step in the diagnostics of cracks is the interpretation of the data collected through visual observations, measurements, and monitoring. At this point, we should have collected enough useful data to identify the likely cause of our cracks, and be able to select an appropriate repair method. As you can imagine, selecting a repair method is not trivial and depends, largely, on the nature of the crack. Fixing dormant cracks can range from simple repointing to replacement of units and localized reconstruction, depending on the extent of masonry damage. Before fixing active cracks, the underlying issue needs to be resolve – for instance, required actions may include foundation stabilization to address ground movement; design and construction of new movement joints to allow the masonry to expand and contract without cracking. Structural cracks may also require installation of steel reinforcement and/or grout injection to restore the original structural capacity. As you can see, the spectrum is wide: don’t ignore a crack and talk to your engineer.

Words & Photos Courtesy of MCAA