The NCMA Unit Design Competition involves the conceptual design of innovative concrete masonry or hardscape units that can be economically manufactured on a block machine (concrete masonry and segmental retaining wall units) or big board machine (concrete pavers). The competition is incorporated into the architectural program at major universities and in many cases is virtually the only exposure these students would ordinarily receive on utilization of concrete masonry or hardscape units.

The competition was initiated at North Carolina State University as the NCSU Blockfest in 1996 through a joint venture of the Carolinas Concrete Masonry Association (now the Southeastern Concrete Masonry Association), Adams Products Oldcastle and Johnson Concrete Products Company. In 2000, the competition was adopted as a nationwide program under the optional ballot system of the National Concrete Masonry Association (NCMA) where members funded the program by voluntary contributions over and above their assessed membership dues. In 2010, the national competition was incorporated into the NCMA Education and Research Foundation as one of its funded programs. The local competitions however continued to be funded locally by producers and/or the local or state association.

From its inception, the long-time champion of the competition is Frank Werner, now Director of Business Development for Oldcastle, who throughout has served as Chairman of the NCMA Unit Design Task Group. “This project has been a grand success,” says Werner. “I remember fondly the first year we held the event, seeing the enthusiasm, genuine interest and excitement in those students’ eyes. After the event I thought to myself, ‘Can it get any better than this?’ I have found out, after 20 years, every year is better than the first. The chance to work with students keeps us industry veterans young and excited about our industry.”

While few, if any, of these student conceptual unit designs have been incorporated into actual production, the benefits are long-term as today’s architectural students are tomorrow’s designers. Veronica (Muth) Slavik, in charge of Corporate Development at ORCO Block & Hardscape in Stanton, California sponsor of the competition at the University of Southern California, is quick to say, “However, we have communicated to the students that should they or an architect that they are working with have a project where one of the units was called into design, we would be happy to participate.”

The exposure the students receive to concrete masonry and hardscape technology creates an indelible impression on these students that extends into their professional career. The local block or hardscape plant tours plus consultations with local producers on efficient unit design and manufacturing capabilities give the students an in-depth insight into these products. Additionally, comments received on their unit designs from the jury – composed of a practicing architect, a landscape architect, a masonry contractor and an industry manufacturing expert – provides these students with an understanding of the design and construction process that will benefit them throughout their professional lives. Relationships are formed that will last a lifetime. “We have exposed over 2,000 students to masonry and hardscape products through our local and national competitions,” says Werner. “Countless times during the year I work with professionals who I originally met at the NC State Blockfest.”

Further, the interaction with professors and design and construction professionals during these competitions also leads to lasting benefits as well. Slavik adds, “It brings our ORCO team together to give back to the industry by doing something fun. Essentially we are hoping that we are inspiring the youth of the architectural world to keep our industry in mind when they are designing, especially since they are at an impressionable stage of their learning. We’ve also enjoyed the judging process. It’s given us the opportunity to reach out to customers and connect with them outside of business. Customers also appreciate the opportunity to give back, support the youth, promote their business, get back on campus of their alma mater (if that’s the case), or even check out recent site work they’ve completed at the school. I hope we can continue to build on the program and extend to many more schools!”

The Foundation also arranges for the top three national finalist teams and their organizing professor to the NCMA Midyear meeting to present their designs – all expenses paid. Cash prizes as well as certificates of achievement are awarded. Very favorable impressions with students, professors and industry reps alike are created. It is one of the most well attended activities at the NCMA Midyear meetings.

Local competitions to date have been established at the following universities with most submitting their winning teams to participate in the national competition:

- Alfred University

- Ball State University

- California Polytechnic State University

- East Carolina University

- Georgia Institute of Technology

- Iowa State University

- North Carolina State University

- University of Nebraska – Lincoln

- University of Southern California

Discussions are ongoing with several other universities about establishing competitions at their school as well. It is envisioned that this list of participating universities will grow substantially in the coming years.

Following is a summary of the winning projects from 2011 through 2014:

2014 – “Y-Block” – North Carolina State University sponsored by the Carolinas Concrete Masonry Association, Adams Products Oldcastle and Johnson Concrete Company

2014 – “Y-Block” – North Carolina State University sponsored by the Carolinas Concrete Masonry Association, Adams Products Oldcastle and Johnson Concrete Company

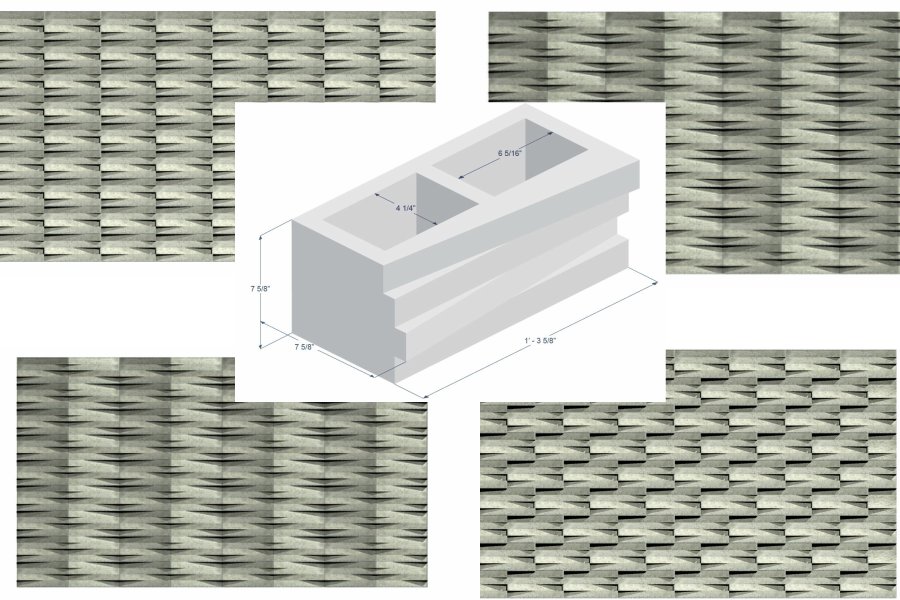

“Y-Block” is a hardscape unit that can be used for a multitude of paver applications and are dimensioned so they can be used in conjunction with other hardscape media such as Holland pavers and bricks or just leaving spaces for grass or gravel to facilitate drainage. Corresponding “C-shaped” units provide a straight edge when needed for sidewalks and parking lots, etc. Standard thickness is 2-1/4 inches. When manufactured to a 3-5/8 inch thickness the units could be used for stairs and supporting walls for elevated planters.

From left: Frank Werner, Chairman, NCMA Unit Design Competition Task Group; Byard Stevens, Carolinas Concrete Masonry Association; Robert Pinon, AIA, MHTN Architects (Juror), Prof. Dana K. Gulling; Olta Kapinova; Andrew Michael Nance; Robert Thomas, NCMA President; Keith Haas, Chairman, NCMA Foundation. (Not pictured: Rhian Lord and Sahar Golabi)

2013: “Medley Block” – University of Southern California sponsored by ORCO

2013: “Medley Block” – University of Southern California sponsored by ORCO

Block & Hardscape

“The design has taken into consideration the new ASTM C90 requirements for web configuration which will result in a higher R-Value. Units all fit together, both in the mold and in the field, in a very successful modular layout,” commented one of the jurors. The protruding portions on the face can be ground for a burnished texture. The webs can also be produced with reduced web area per the new ASTM C-90 requirements for increased energy efficiency and reduced weight and material.

From left: Rick Muth, ORCO; David Nicholson; Prof. Eric Nuhlman; Morenike Somoye; Stephanie (Muth) Watts, ORCO

2012: “LiveBlock” – North Carolina State University sponsored by the Carolinas Concrete Masonry Association, Adams an Oldcastle Company and Johnson Concrete Company

2012: “LiveBlock” – North Carolina State University sponsored by the Carolinas Concrete Masonry Association, Adams an Oldcastle Company and Johnson Concrete Company

“LiveBlock” is a masonry unit that essentially is produced with a veneer already attached to the block. The webs attaching the veneer are much smaller than those of the backup providing a sizeable cavity space for drainage and insulation. The insulation cavity can be up to 6-inches resulting in very high R-Values and very sustainable wall sections. Additionally, if the webs attaching the veneer meet the ASTM C-90 minimum web requirements and the veneer itself meets the minimum face shell requirements, the full thickness of the entire unit can be considered effective for structural purposes including reinforced masonry design.

From left: William Holden, Chairman, NCMA Education and Research Foundation; Prof. Dana K. Gulling; Stacy Goodman; Elizabeth Gutiérrez; K. Matt Teti, L. Katy Liang; Frank Werner, Chairman, NCMA Unit Design Competition Task Group

2011: “Pivot Block” – Georgia Institute of Technology sponsored by Block USA

2011: “Pivot Block” – Georgia Institute of Technology sponsored by Block USA

“Pivot Block” consists of a block split into four horizontal segments pivoted around an axis in the center of the block as shown in the attached figure. Through various block rotations and bond variations, a host of architectural effects can be obtained such as stack bond, mirrored stack bond, running bond, and mirrored running bond.

From left: Victor Cochoff; Joyce Gemarino; Kristen Kellogg; Devaqnuyah Reuven. (Not pictured: Joshua T. Word and Prof. T. Russell Gentry)

Full final reports of the above competitions including the presentations of the second and third finalists for are posted on the NCMA Foundation web site for the following years: [2014], [2013], [2012], and [2011]. (Go to https://ncma.org/foundation and click on “Foundation-Sponsored Programs“ in the menu on the right, then on “Funded by: Research Grants” and then “Final report” for the following projects: 2013.057, 2012.013, 2011.030, and 2010.020 respectively).

Further information on the Unit Design Competition itself can be found on the NCMA web site at https://ncma.org/foundation, then click on “Unit Design Competitions” in the right menu. Included on this page is a link to guidance on “How to set up Unit Design Competition at Your University.” Alternatively you can contact Jason Thompson (jthompson@ncma.org) or Frank Werner (Frank.Werner@oldcastle.com) directly.

Note: The NCMA Foundation Unit Design Competition is oftentimes confused with the two other student design competitions also funded by the Foundation – the Architectural Student Design Competition and Engineering Student Design Competition. Information on the latter two can be found on the same web site https://ncma.org/foundation and clicking on “Student Design Competitions Guidelines” in the right menu.