Making Blocks From Wine

Canadian company makes concrete with recycled wine bottles

?? |

|

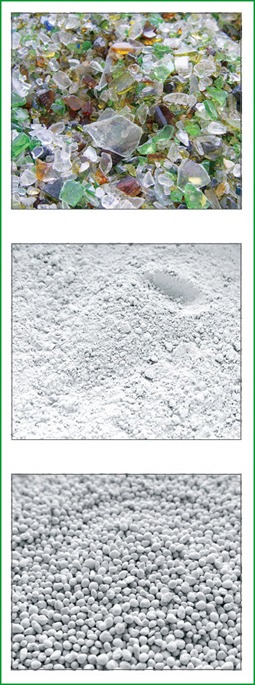

| The Poraver facility takes glass shards (top), grinds them into glass flour (middle), and creates small glass pellets (bottom) that are used in place of sand as an aggregate in concrete manufacturing at Atlas Block. |

Atlas Block, a family-operated company based in Midland, Ontario, is producing concrete construction and landscaping products using post-consumer recycled content.

Contrary to what many diligent users of residential recycling programs might think, colored glass is harder to recycle in basic municipal facilities, and, therefore, often ends up in landfills. Operating with a corporate philosophy of being responsible producers, the company is firmly “on the sustainability page,” says Atlas Block CEO Don Gordon.?? Through intensive research and development, Atlas Block has developed a recipe that includes up to 36 percent post-consumer recycled glass in their concrete products.?? The products are LEED certified.

The team at Atlas Block experimented with more than 100 mix designs over four years before finding success. One of the main challenges is preventing the alkali silica reaction that occurs when glass and concrete are combined.?? An alkali silica reaction can cause the concrete mixture to expand significantly and crack, resulting in serious structural damage.

To solve this problem, Atlas Block partnered with Poraver, a neighboring local company that uses a special process to coat tiny beads of recycled glass, thus preventing the glass from reacting with the concrete. The Poraver facility in Innisfil, Ontario, has the capacity to convert 26,000 tons of product per year, which is about equal to keeping 40 million wine bottles out of landfills. At the Poraver facility, recycled glass is placed into a mill where it is crushed into glass flour and combined with binding agents, expanding agents, and water. The material is mixed in an industrial mixer, and poured into a palletizing dish that forms it into tiny beads. Atlas Block then uses tiny glass beads as an equal replacement for the sand component in traditional concrete manufacturing.?? This means that an eight-inch concrete block by Atlas Block is actually about four pounds lighter than an average eight-inch concrete block.

The company is actively researching even better ways to improve its concrete products. A new state-of-the-art plant in Hillsdale has allowed Atlas Block to manufacture a wider range of products with a greater degree of accuracy, using laser precision and touch-screen control technologies. They can now manufacture concrete that looks like pebble stones and granite slabs for landscaping. Gordon also is aiming to soon be able to manufacture a concrete block made with up to 80 percent post-consumer recycled content.

“Over the years, there have been very few radical changes in concrete,” Gordon says. “Our goal is to transform the industry.”

|

|

|

|