March 2015

Saw Blades

By Jim Cook

The thing about blades is that they can always be a little sharper.

That’s a maxim the masonry blade industry has taken to heart as it continues to innovate, making blades more versatile, more durable and less expensive to produce.

The masonry blade industry has done much to hone its products in recent years, finding ways to make a variety of products to appeal to a variety of needs. Whether it’s a tough, durable blade with an extended lifespan or an inexpensive blade for DIY users of masonry saws, the industry has stepped up to meet the demands of its clients.

From the experts

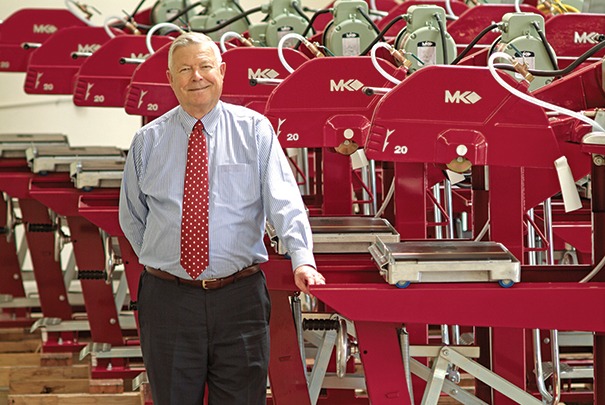

Robert Delahaut, president of MK Diamond, has spent decades in the masonry blade business. Delahaut has seen many improvements in the industry in that time. He says one of the most game-changing innovations of the last 20 years has been the development of laser-welded blades.

Delahaut says this form of production allows for more robust blades with smaller diameters. He adds, “Everyone’s trying to make a finished product that is lighter weight, more portable and safer.”

Doug Closter is a product manager for DeWalt. Closter says a major industry trend has been a narrowing in the quality gap between sintered blades and welded blades. Closter says sintered blades steadily are becoming more durable, bringing them closer to matching the longevity of more expensive, welded blades.

Delahaut says that, in recent years, demand has increased greatly for dry-cutting blades for small, handheld saws. According to Delahaut, demand for wet-cutting blades is decreasing as more reliable and resilient dry-cutting blades are hitting the market.

Closter currently sees a large demand for multi-purpose blades that can cut through a variety of materials such as brick, block, rebar, etc. However, he sees a growing demand for specialized blades as manufacturing techniques improve and manufacturers improve upon their ability to develop blades that can meet clients’ specific cutting needs.

Both Delahaut and Closter agree that automation is helping to reduce costs for masonry blades. Delahaut says modern manufacturing facilities can turn out blades more quickly and with fewer flaws, allowing them to be sold at lower prices.

“One person can make 10 times more blades in eight hours than they could in the ‘50s and ‘60s,” Delahaut says.

Closter concurs, “We’re looking forward to advancements in technology on the manufacturing side that will continue driving down price.”

Also helping to drive down prices is a greater availability of the synthetic diamonds used in masonry blades. Delahaut says globalization has helped to make the sourcing of synthetic diamonds used in masonry blades much more competitive. Because manufacturers now have more potential suppliers of raw materials, they are able to manufacture masonry blades at a lower cost.

A changing market

Although masonry blades and their manufacture continue to evolve, those aren’t the only changes occurring in the industry. E-commerce is having a huge impact on how masonry blades are sold, disrupting traditional channels of distribution. Catalogs, brick-and-mortar stores and direct sales are diminishing, as a larger number of blades are sold online directly from manufacturers or third parties. Online commerce also is opening up the industry to more customers, as home repair enthusiasts are buying more masonry blades. Even Amazon is selling diamond blades, says Delahaut.

Delahaut adds that casual users of masonry blades aren’t the only people going online to buy blades. Big contractors also are increasingly turning to e-commerce to purchase the blades they need. The explosion in e-commerce is causing consolidation in the industry, Delahaut says, adding that customers want to stick with established companies. That leaves little room in the industry for start-ups or smaller competitors.

“If you don’t have a brand identity in this market, it is almost impossible to get market share,” he says. “…there’s not a lot of room for mom-and-pop type operations anymore.”

From the field

Despite all the advancements in technology and marketing, the fundamentals of making and selling masonry blades remain the same: Build a blade that does what is promised and sell it at a reasonable price.

Doug Burton, president of Whitman Masonry in North Carolina, says he has a simple test for the masonry blades his masons use. He sends them out to the field and, unless he hears back from his masons, he sticks with those blades. “If something’s not working, you’ll hear something,” he says.

Burton says he prefers more durable blades, even if they cost a little more. “I don’t often change vendors,” Burton says. “When I find a good blade, I stick with it.”

Jim Cook is a freelance writer based in Dothan, Ala. A veteran of daily newspapers and trade publications, he has experience writing on a variety of topics. He can be reached at jim.cook.is@gmail.com.

Product to WatchDiablo HardieBlade Circular Saw Blade |

The Diablo HardieBlade from Northern Tool is a PolyCrystalline Diamond- tipped (PCD-tipped) fiber cement blade that can generate up to 5 percent less respirable dust, while delivering the longest life in all fiber cement materials. Diablo PCD HardieBlades feature a spark-eroded Triple Chip grind for long life – up to 60 times the life in fiber cement of conventional carbide blades. The blades utilize a laser-cut thin kerf design to give fast and precise cuts, while producing less dust and waste. Diablo PCD HardieBlades are perfect for fulltime use in heavy-duty applications like cutting multiple pieces of fiber cement board.For more information, visit www.northerntool.com. The Diablo HardieBlade from Northern Tool is a PolyCrystalline Diamond- tipped (PCD-tipped) fiber cement blade that can generate up to 5 percent less respirable dust, while delivering the longest life in all fiber cement materials. Diablo PCD HardieBlades feature a spark-eroded Triple Chip grind for long life – up to 60 times the life in fiber cement of conventional carbide blades. The blades utilize a laser-cut thin kerf design to give fast and precise cuts, while producing less dust and waste. Diablo PCD HardieBlades are perfect for fulltime use in heavy-duty applications like cutting multiple pieces of fiber cement board.For more information, visit www.northerntool.com. |