December 2015

All Images Provided by General Shale

With winter weather arriving, masonry chimneys face months of prolonged exposure to wind-driven rains and melting snow. Continuous subjection to inclement weather can result in chimney deterioration, which, in turn, can present a potential safety hazard for the building’s occupants.

With winter weather arriving, masonry chimneys face months of prolonged exposure to wind-driven rains and melting snow. Continuous subjection to inclement weather can result in chimney deterioration, which, in turn, can present a potential safety hazard for the building’s occupants.

That’s why it is important to follow this checklist when constructing a masonry chimney in order to avoid as much water penetration as possible. Proper design, along with quality construction and materials, is essential for preventing prolonged contact with water – and for avoiding any resulting damage.

Chimney cap

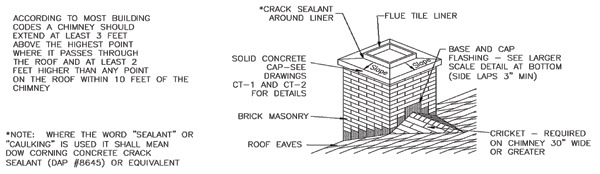

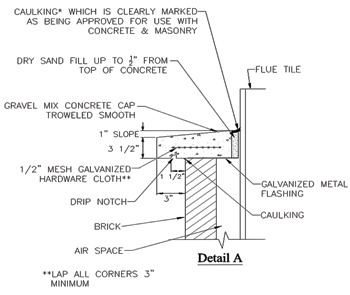

For maximum weather resistance, a chimney cap should extend beyond the chimney walls and incorporate a drip feature at its edge. This prevents water (from melting ice or snow and straight-down rain showers) from streaming down over the chimney walls for long periods.

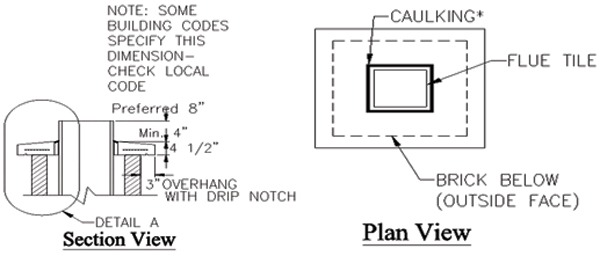

The flue tile should project at least four inches above the top surface of the cap. (This requirement may be greater in some code jurisdictions.)

In most cases, the cap material should not be bonded or mechanically anchored to the flue tile, as vertical movement of the flue tile due to thermal expansion will be transferred to the cap material and crack the cap or lift it from its bedding material This opens it to water penetration. Instead, there should be a clear opening between the cap material and the flue tile that is wide enough (3/8 to inch) to receive a resilient caulking material and the flue tile.

The cap should have a positive slope away from the center (or flue tile) toward the edges, so that water will drain away from, rather than toward, the flue tile.

Many chimney caps consist merely of a trowel-applied, parge coat of mortar, often finished to a feather-edge at the perimeter. These types of “caps” usually crack due to shrinkage of the mortar soon after construction and provide ready channels for water penetration. Often, the thin mortar becomes de-bonded from the brick courses below, forming a horizontal crack, which serves as another avenue for water penetration.

Metal caps and hoods can also be constructed to provide weather resistance to chimney tops. If concrete is used as the cap, it should be thick enough to permit the installation of metal reinforcement. To be durable, such reinforcement should be galvanized.

Metal caps and hoods can also be constructed to provide weather resistance to chimney tops. If concrete is used as the cap, it should be thick enough to permit the installation of metal reinforcement. To be durable, such reinforcement should be galvanized.

All concrete or masonry caps should be underlain by flashing. With flashing under the cap, any water entering the cap materials will be mostly confined to the cap, and will be largely prevented from trickling down into the brickwork below.

Chimney walls

Any obvious cracks or openings in the chimney walls should be regarded as suspect points for water penetration. These include separating cracks between brick units and mortar joints, cracks that extend through brick units and adjoining mortar joints, “bug holes” in mortar joints (where mortar doesn’t completely fill the joint), badly cracked or spalled brick, and other openings, such as those that may have been created by fasteners used to attach wires or antennas.

Any obvious cracks or openings in the chimney walls should be regarded as suspect points for water penetration. These include separating cracks between brick units and mortar joints, cracks that extend through brick units and adjoining mortar joints, “bug holes” in mortar joints (where mortar doesn’t completely fill the joint), badly cracked or spalled brick, and other openings, such as those that may have been created by fasteners used to attach wires or antennas.

Sloped or projecting surfaces, such as those created by corbelling or “racking,” impede the flow of water and increase the amount of contact time water has with the masonry. Often, such features also are the site of separation cracks and exposed core-holes of brick units. They can, therefore, be major contributors to water permeance in the masonry.

Mortar joints play an important role in the water resistance of brick masonry. For chimney construction, only the concave, vee or compacted grapevine joint should be used. These joints provide two features essential to the shedding of water: a sloping profile and densified outer surface.

Raked joints are to be avoided for chimney constructions (as well as all other weather-exposed masonry), since they provide ledges for the accumulation of water and an outer surface that is usually coarse and non-densified. Head joints should also be avoided because they are often not filled completely to the full-bed depth of the brick. They are the most common source of leakage in brick masonry.

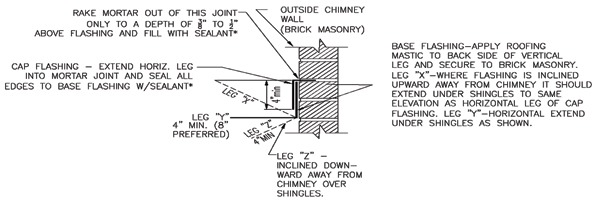

Roof-to-chimney flashing

Flashing from the roof to the chimney is necessary to prevent water from leaking into the roof area where the chimney penetrates the roof. The “flashing” is normally inserted in two parts – step flashing, which is inserted under the roof shingles (or other roofing materials), and stepped counterflashing, which comes out of the chimney walls and turns down over the step flashing. The vertical legs of the flashing and counterflashing should be caulked with a construction sealant to prevent wind-driven rains from blowing into these areas.

Flashing from the roof to the chimney is necessary to prevent water from leaking into the roof area where the chimney penetrates the roof. The “flashing” is normally inserted in two parts – step flashing, which is inserted under the roof shingles (or other roofing materials), and stepped counterflashing, which comes out of the chimney walls and turns down over the step flashing. The vertical legs of the flashing and counterflashing should be caulked with a construction sealant to prevent wind-driven rains from blowing into these areas.

When the dimension of the chimney parallel with the roofline (usually regarded as the chimney width) exceeds 30 inches, a cricket is usually required. Use of a cricket for chimneys is effective in aiding roof drainage from behind wide chimneys, again minimizing contact time of the water with the chimney, and preventing ponding of water.

Flashing materials should be metal – preferably copper, galvanized steel or stainless steel. Some plastics may be suitable, but are less durable.

Omission of flashing and counterflashing at the roof/chimney intersection, and the substitution of construction sealants (caulks) for these materials, is considered inferior workmanship. The weather-resistance of the structure is unreliable in the absence of these materials.

Caulking materials

Suitable caulking materials for use with products which contain Portland cement – such as mortar and concrete – must not contain acids. For this reason, silicone caulks must be carefully selected, as many of these have acid curatives, which prevent proper bonding to mortar and concrete. Such caulking used for joints may look watertight, but in fact may leak due to improper or incomplete bonding.

Caulking materials should be able to accommodate whatever movement takes place at a joint without tearing the joint material or pulling it loose from the adjacent materials.

The arrival of Old Man Winter doesn’t necessarily pose a threat to masonry chimneys. Careful attention to these important installation steps will ensure that your masonry chimney is constructed to withstand the elements for many years, no matter what the weather brings.

Masonry NewsSpider Offers Access for Chimney Stack Maintenance |

Spider, a division of SafeWorks, recently offered a custom, suspended scaffolding solution for tuck-pointing and brick repair work on the 125-foot-tall chimney stack at Lane Tech High School in Chicago. Spider, a division of SafeWorks, recently offered a custom, suspended scaffolding solution for tuck-pointing and brick repair work on the 125-foot-tall chimney stack at Lane Tech High School in Chicago.

IWG Inc. was familiar with Spider’s specialization in suspended applications. The company turned to Spider for a custom solution. Spider designed, built and installed a rigging star equipped with three swing stages and two Beta Max Gemini material hoists. The rigging star was lifted into place by a crane and then counterweighted, eliminating the need for anchoring into the structure. Additionally, Spider offered all rigging services as well as on-site user training to ensure the safe operation of the equipment. “We were genuinely impressed with Spider’s capabilities through every phase of this project, from the initial design to the on-site supervision,” says Al Arreguin, owner and operator with IWG Inc. “Their Chicago team did a fantastic job meeting our challenges while keeping us safe, on schedule, and within our budget.” For more information, contact Heidi Krueger at Heidi.Krueger@SafeWorks.com. |

In the NewsHistoric Chimney Saved in Baku |

Cintec International is ensuring that a historic industrial chimney will be at the heart of The Twin Towers Port of Baku scheme.A demolition-threatened, historic chimney in the Azerbaijan capital of Baku now will be the center point of a multi-million dollar shopping complex. Cintec International has been commissioned to carry out complex structural preservation work on the chimney later this year.Built in the 1900s the chimney is the focal point of a regeneration project to establish Baku as an up-and-coming center of commerce and technology.Original designs for the development, which will be called The Twin Towers of Port Baku, planned to have the chimney pulled down to make way for the modern shopping complex. However, when the president of Azerbaijan saw the plans, he requested that the historical chimney be restored instead and become a central feature of the development. The result is a design that is representative of the futuristic vision for Azerbaijan, while retaining important elements of its industrial history. Cintec will be using its patented anchor to secure the chimney by drilling into the structure from the top and feeding 24 meters of anchors in to the walls of the chimney to secure it for generations to come. The chimney is one of the most delicate structures that Cintec has ever worked with. It has required the company to design thinner connecting anchors, especially for the project. The circular structure of the building also means that Cintec will have to use laser keyhole technology to achieve the precision necessary to successfully position the anchors. The work is expected to take 12 weeks to complete. “This is another exciting contract for us at Cintec, and we’re delighted to be involved in helping to maintain this historic chimney as part of Baku’s redevelopment,” says Peter James, managing director. “We’re passionate about maintaining and restoring historical buildings for future generations, so we were very pleased to hear that the chimney was going to be saved and honored to be asked to carry out the work.” The chimney is just one of Cintec’s ongoing structural preservation projects. The company has worked in Egypt restoring its historical buildings for 18 years and has undertaken restoration work on mosques, temples and both the Red and Step Pyramids. Cintec anchors also have been used to restore other historically significant buildings across the globe, including Windsor Castle, the parliament building in Canada and even the White House. |

This article was contributed by General Shale, www.generalshale.com.