Words and Photos: Steven Judd, Technical Director at Interstate Brick/H.C. Muddox

Historically, building codes were written so that code-compliant building designs, when properly constructed, would preserve life in the aftermath of a given defined “design event,” which translated to a condition of collapse prevention – design and construct the building, so it doesn’t fall down and injure anyone. This was a good place to start, as one has to start somewhere, but there are other important criteria besides collapse prevention. If a building is damaged to the point where it cannot be safely occupied, even if it is still standing, it no longer maintains its intended purpose or functionality. It may be slated to be demolished if repairs are too costly. Then one gets to start over with a new building.

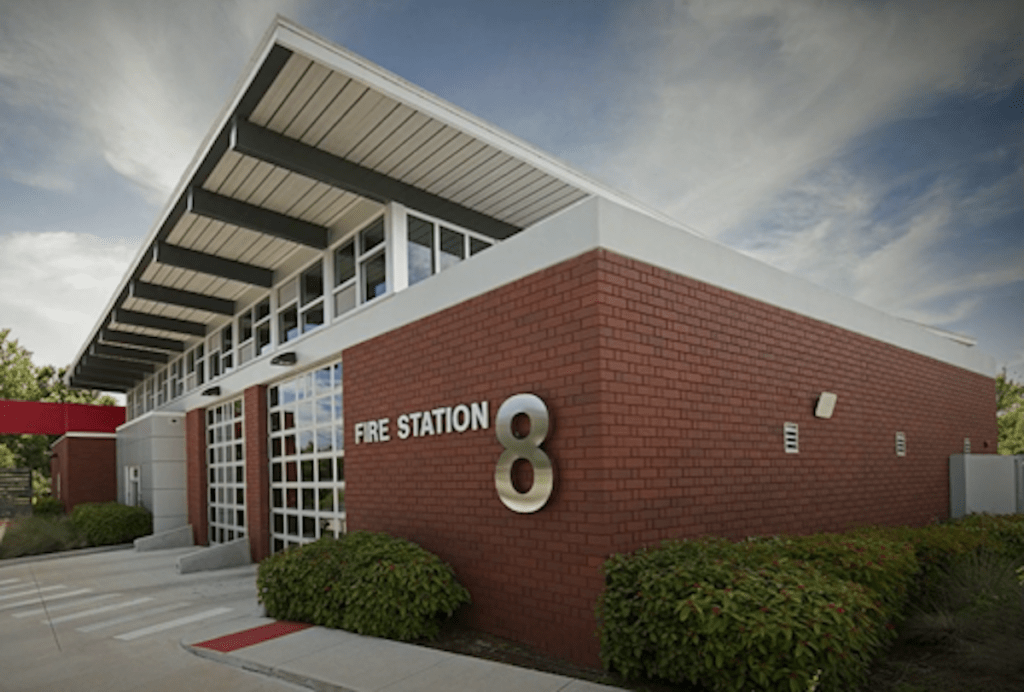

There is a whole group of buildings that need a higher level of performance than just collapse prevention. Some buildings need to be serviceable, or functionally adequate and occupiable, after whatever the controlling “design event” occurs, whether that be tornadoes, hurricanes, wildfires, tsunamis, earthquakes, floods, avalanches, other natural disasters, and even acts of terrorism. This group of buildings is generally called “essential facilities” due to the nature of the procedures, processes, or occupants that use the facility. Among such buildings are communications centers, power grid buildings, hospitals, emergency response centers (like police stations and fire stations), defense critical military installations, fuel and electrical transfer structures, to name a few.

Schools, either portions of or the entirety, may be deemed essential facilities by the local jurisdiction having authority and may be part of a community’s emergency response plan; a facility to house and care for a portion of a community, in an emergency, for a limited amount of time. As an example, the Astrodome sports arena in New Orleans was used to house upwards of 25,000 people in the aftermath of Hurricane Katrina, which caused the collapse of the levees that protected the city. Mass flooding ensued, driven by the storm surge associated with the hurricane.

Essential facilities have some special design requirements – requirements that help them perform better than other facilities during and after a design event; “better,” meaning incurring less damage. This is made possible by implementing several approaches, which include: increasing design forces, increasing the number of structural elements that resist the applied loads (providing redundancy) and designing connecting elements for capacities that exceed the elements to which they are connected – so the connections do not fail. These types of buildings, these essential facilities, are durable and robust by design, and these types of buildings enhance resiliency for individuals, neighborhoods, and communities. Many designers choose structural clay masonry for use on essential facilities due to its high strength, and exceptional performance in seismic areas.

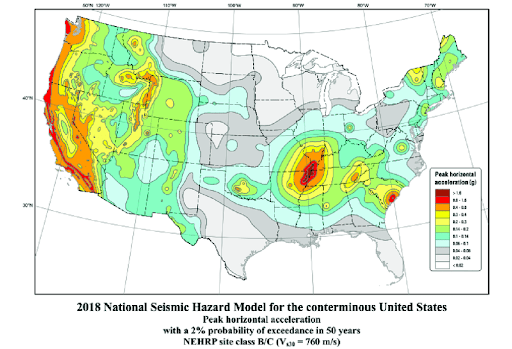

Of particular destructive effect is earthquakes. Unlike hurricanes, which are generally well-tracked in advance and have probabilistic paths defined, and tornados which often have some precursor events or warning systems, earthquakes generally occur at random times and random places with no warning. Earthquakes generally occur along or near some established geologic feature, like a fault line or where the earth’s tectonic plates collide, rub together, or pass over/under one another. Some such features are well known and well established (San Andreas Fault [CA]; Wasatch Fault [UT]; New Madrid Fault [TN, AR, MO]; Woodstock and Ashley River Fault [SC]), and others are unknown until an earthquake occurs. Consider the August 23, 2011 earthquake near Washington D.C., which surprised pretty much the whole population in that area.

As one can see from this FEMA map, most areas of the conterminous US have seismicity, to some extent or another, with some specific areas having extreme seismicity. Designers must consider the extreme forces from seismic events when designing structural systems and selecting building materials.

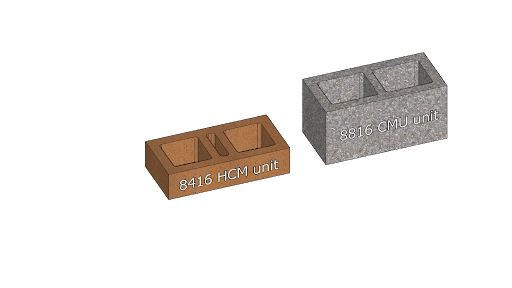

How can structural masonry be used to solve the puzzle of durable and robust buildings? First, let’s refresh our understanding of the types of units: There are two broad categories of structural masonry units: there are Hollow Clay Masonry (HCM) units and Concrete Masonry Units (CMU). Both types of units are specifically designed to receive reinforcing steel (vertical and horizontal) and to be either fully or partially filled with cementitious grout, which bonds the rebar to the masonry units, making a monolithic element similar to reinforced concrete elements/systems.

Figure No. 3: Structural Masonry Units

Next: structural masonry is a very rigid material when used in an appropriate fashion. Structural masonry typically produces a very stiff building. Stiff buildings do not sway or drift back and forth in a seismic event as much as some other building types, and as such, the various materials and systems housed in the building do not have to be designed to accommodate large story drifts from floor-to-floor. Structural masonry buildings generally have a fraction of the story drift of steel or concrete moment frame buildings. Because the building is more rigid, interior furnishings, when they are properly braced, tend to experience less damage.

Reinforced HCM has capacities very similar to reinforced concrete facilities but with the organic look and the aesthetics of clay masonry. It is not uncommon to have HCM design strengths (f’m) anywhere from 3,500 psi to 4,000 psi, and sometimes higher, as compared to typical poured-in-place or tilt-up concrete design strengths (f’c) of 3,000 psi to 5,000 psi for most of the single- to four-story structures. In some respects, reinforced HCM is much like reinforced concrete utilizing left-in-place forming – the “forming” being the HCM units. CMU is also used for reinforced structural masonry buildings but typically has design strengths around 2,000 psi or 2,500 psi. Some structural designers still use f’m = 1,500 psi design strengths for CMU based on older editions of the prevailing manufacturer’s ASTM specifications.

The higher strength capacity of the HCM has some efficiencies that can get overlooked, such as reduced wall widths (increasing usable interior space), reduced reinforcing (less material; grout and rebar), the fired surface of the HCM units have a more durable finish; it doesn’t damage as easily as CMU. It never needs to be painted.

In some cases, the delivery time for structural masonry can reduce construction time as compared to some steel-framed facilities when considering production, supply chain, and fabrication time impacts for structural steel. The bearing/shear walls can be installed while structural steel roof framing elements are being fabricated. One state masonry association was recently able to swap reinforced structural masonry for the gravity and lateral load resisting system on several buildings that were designed and bid using structural steel framing for a reduction in construction time and for a reduced cost.

One added benefit that enhances the resiliency of structural masonry buildings is the fact that they are non-combustible; they don’t burn. The non-combustible structural masonry walls help reduce the spread of fire. When combined with non-combustible floor and roof construction, incidental fires are well contained and do not spread. The structural masonry walls are effective 100% of the time. The well-known San Francisco earthquake of 1906 caused a lot of damage due to the ground shaking, but by far, the most damage occurred during the ensuing fires. The historic Palace Hotel, constructed in 1875 of multi-wythe fired clay brick masonry walls, which were strategically strapped with steel reinforcing bands, survived the ground shaking caused by the earthquake, but the interior was consumed by the resulting uncontrolled fires in the city. The masonry walls remained intact.

One last benefit that enhances resiliency is that of ballistic-rated HCM, which is available from one brick manufacturer. This material has all the same benefits as previously discussed, in addition to being rated for munition impact resistance up to .50-caliber. This can be used for secure facilities, hardened entrances, and facilities for the protection of high-value assets – things or people.

Overall, the higher-strength HCM materials have the capacity to provide durable, robust, resiliency-enhancing facilities, including code-required essential facilities, that can withstand seismic events and many other naturally occurring and human-caused disasters. These facilities provide a level of security and peace of mind not found with other building materials while providing beautiful structures for any community.