Words and Photos: Shawn Nelson, President at Elite Distribution

With such a large variety of diamond blades in the market, choosing the right diamond blade for a specific job can sometimes seem overwhelming. The consequences of not using the correct diamond blades can range from poor performance to ruined blades. For the mason contractor, making the right selection when purchasing a diamond blade is crucial, but the amount of options can make it seem like an impossible task. Between navigating the wide range of styles, fancy designs and marketing lingo, sorting through all of the sizes and specs and figuring out how much you should spend can be downright exhausting.

Before you decide, keep in mind: There isn’t one best diamond blade that’ll work for everything. It’s important to consider your personal needs when you shop.

What To Consider When Choosing A Diamond Blade

Choosing the correct blade for the application will determine speed of cut and life of the blade. Select a blade based on which type of material you will be cutting. For example, a diamond blade for cutting block shouldn’t be used for cutting brick. Remember, wet blades have to be used with water while dry blades can be run dry or with water.

The type of saw you’re using, the material you are cutting, and the size of the job will all play a role in determining which diamond blade is best suited for your needs. You also want to consider cost, convenience, durability and any job site issues — i.e., whether water is available or noise levels come into play. We’ll break down these topics (and more!) to help you decide.

Price

For smaller jobs or occasional use, a lower-priced blade may be the best choice. Keep in mind, the lowest-priced/quality blades can come with safety concerns. For larger jobs or regular use, it is usually best to get a higher quality diamond blade for a better overall cost per cut. However, like with many things, the most expensive blade is not always the best value.

Diamond Segment Height

Segment height can be misleading when determining a diamond blade’s value. It only comes into play when comparing blades of equal quality. A high quality blade with a short segment is often a better value than a low quality blade with a taller segment. The factors that are most important are the size and quality of the diamonds along with the overall diamond concentration.

Buying Tip: The Diamond Concentration Sales Pitch. Don’t be impressed by claims of high concentration. Too much diamond can make the blade too hard for lower power saws. For example, 35% concentration blades are only for 30 horsepower and larger saws. Masonry saws do no have enough power to run a blade with that high of concentration.

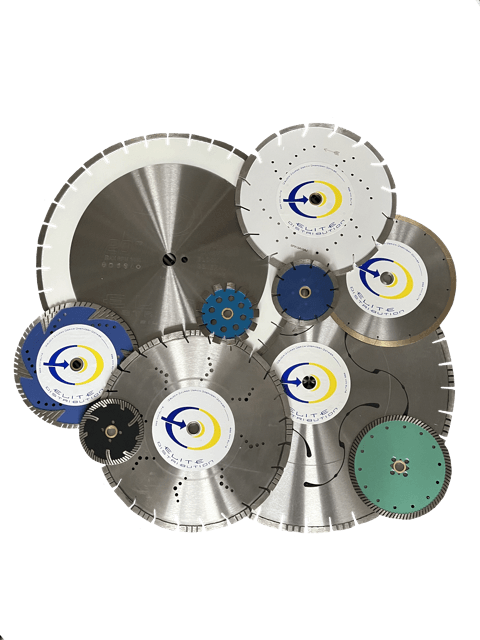

Types of Diamond Blades

Segmented and turbo diamond blades are the most popular types, but additional types have become more common to give contractors a variety. Within each type, you can still find a wide range of quality levels and price points. Here’s how to select your diamond blade type:

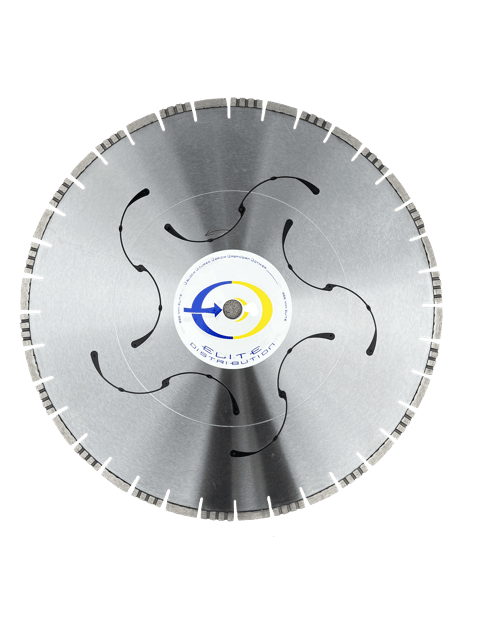

- Segmented – Longer blade life. Chipping may occur. Segmented blades have gullets which are the spaces between the segments. They allow for air flow, cooling and slurry removal.

- Continuous Rim Turbo – Faster cutting, shorter life. Less chipping.

- Segmented Turbo – Faster than segmented, longer life than turbo.

- Continuous Smooth Rim – Little to no chipping.

Cores

- Sandwich Silent Core – (Greatest sound reduction)

- Laser Cut & Laser Cut Epoxy Filled Cuts- (Limited sound reduction)

Where to Buy Diamond Blades

Shopping Local

Some significant benefits of buying local is that you get to see the product and salesperson in person and usually has same-day availability. There certainly is value in dealing with someone face to face and having a product that you can get on short notice. That being said, local shopping can limit your choices, as it’s common for only offer one or two brands.

Shopping Non-Locally

This route can be a great alternative (or addition) to a local supplier. It can be convenient to simply call, text or email in an order and have it delivered to your door or even job location. Note that some non-local suppliers can offer a better price because they don’t have the overhead of a brick-and-mortar store. The more specialized a supplier is in diamond blades, the more knowledgeable they should be. They also usually offer a much wider selection. Shipping charges can be a possible disadvantage when buying non-locally. If there are, ask the supplier if there is a way they can be avoided.

Return Policies and Warranties

It’s difficult to know whether your diamond blade is a good fit without actually using it and the last thing you want is to be stuck with a blade that doesn’t work well. The good news is that most suppliers will stand behind their product. Just check whether there are any hidden return fees and how you go about making the return to avoid a headache later on.

Some suppliers may even offer a free sample diamond blade to try out. A salesman may have the ability to do this on their own, but often need approval from a manager or owner. Having an honest, upfront and respectful conversation with the supplier is the best way to receive a free sample. After all, just as you do not want to work for free, suppliers do not want to give things away for free unless they know it will receive a fair evaluation and a good faith opportunity at future business.

Finding the right diamond blade can be simplified by working with a supplier that fully understands the product as well as your needs. A supplier that puts their customers’ success at the forefront will demonstrate their desire to do what it takes to forge a long lasting partnership.