Words and Photos: Guy Erickson, Trimble Business Manager- Contractor, Structures Division, USA

For Jason Hobbs, the owner of Hobbs Masonry, the path to 3D was a long time in the making. Early in his career, Hobbs taught himself CAD, and looking back, realizes that he was trying to achieve the level of efficiency he gets by using BIM-M (BIM for masonry) today. “In an indirect way, I think I’ve been looking for the right solution for a really long time, and there’ve been lots of different iterations along our journey to 3D,” said Hobbs.

Like many contractors, Hobbs was devoting a lot of resources to coordinating information between trades. “I would receive steel shop drawings for a job, sit on the tailgate and do a bunch of math calculations to verify they would work,” he said. “Then, the next day, I would get a different set of drawings and do it all over again. Over time, it seems like it’s gotten worse. The construction drawings we get are more incomplete than they’ve ever been and, as a result, aren’t well coordinated between trades.”

To save time and money and improve collaboration with other trades, Hobbs decided to take ownership over the drawings. “We’re responsible for it, whether we like it or not,” said Hobbs. “I would rather own the responsibility from day one than try to fight through it while building a project because bad documents impact what we’re able to do on a job and how well we can do it.”

Hobbs began using a CAD software for 2D drafting, design, and documentation but was doing a lot of the line drawings to determine the intent of construction documents. “We started working with a supplier who would model and provide good material counts,” said Hobbs. “We worked with them for a while because their drawings were better than we’d seen anywhere else, but as we started asking for more, such as drawings including rebar, the process slowed down.”

Overcoming Common Misconceptions about BIM

Technology, such as BIM-M that opens the door to business improvement has come a long way but is still met with resistance due to misconceptions based on limited or incomplete information. For example, many think that BIM-M is expensive when, in reality, it’s fairly inexpensive and can quickly deliver a solid return on investment. Those hesitant to explore BIM-M also think that it requires previous CAD or 3D experience. Although previous experience is helpful, anyone with a building background who can read plans and has a desire to learn can take advantage of BIM. In fact, it’s important to note that real world industry experience is just as valuable as any CAD or 3D background. They truly form two sides of the same coin.

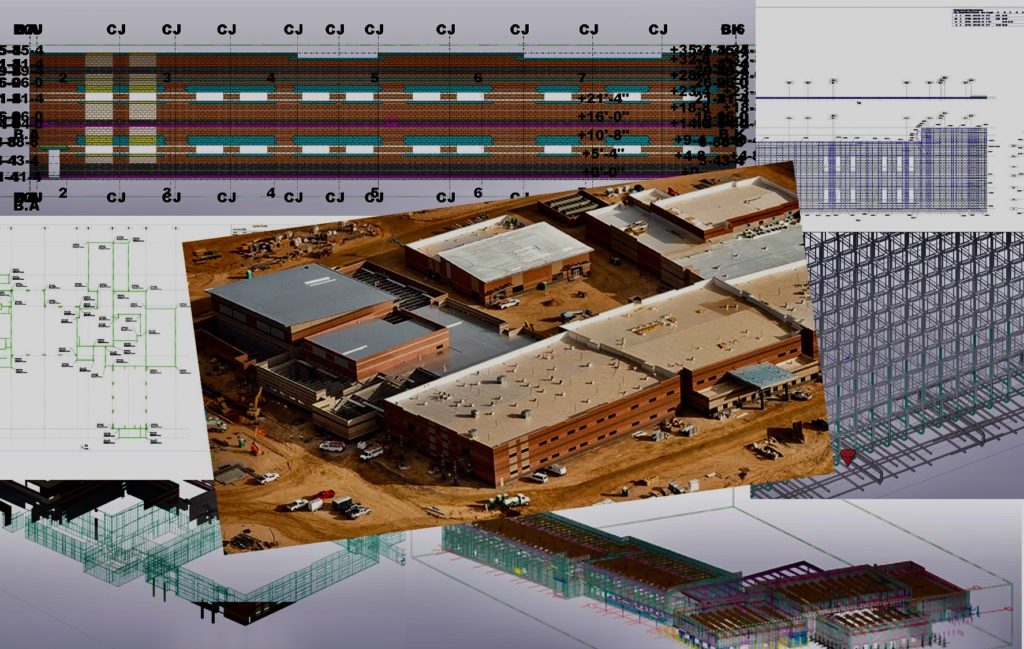

Resistance wasn’t an issue for Hobbs. “I knew that with the right software, we could create 3D models and use them throughout preconstruction and construction,” he said. While attending World of Concrete, Hobbs came across Trimble’s Tekla Structures BIM software. A variety of disciplines in the concrete industry, including mason contractors, self-perform general contractors, rebar detailers and formwork manufacturers, rely on Tekla Structures to work smarter, faster and better together. The software’s value is extended by collaboration platforms, such as Trimble Connect, that make it possible to share 3D models and the data within them across project stakeholders, from the office to the field, throughout the design and construction process.

Working Smarter, Faster and Collaborating with Ease

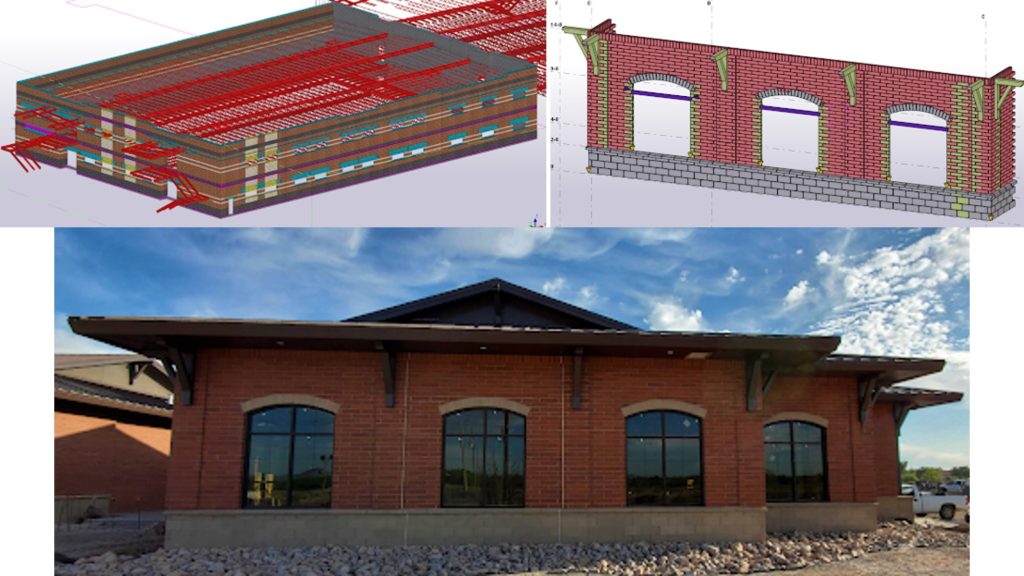

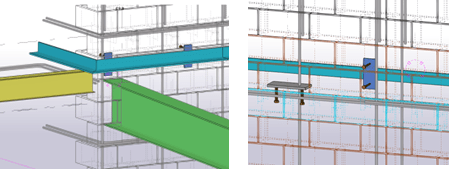

BIM is all about sharing and managing the multitude of information that can be used to enrich models. During the design process, BIM-M can be used to quantify masonry units, required reinforcement and hardware and accurately report on quantities as changes are made. A model’s 3D geometry can expedite the creation of 2D drawings with an intelligent bill of materials and allow us to quickly create sections and details with just a few clicks. The ability to tag each block with generic and unique attributes, such as unit type, finish or color, saves time on deliverables and reporting. More importantly, BIM-M allows stakeholders to understand the spatial relationships of elements within a design and how they interact with the other structures, systems and components on a project. With that ability, it’s possible to design proactively and, with clash detection, resolve conflicts before construction begins.

Using Tekla Structures has brought these benefits to Hobbs Masonry and increased productivity, reduced errors and allowed the company to collaborate within its office and between trades with ease.

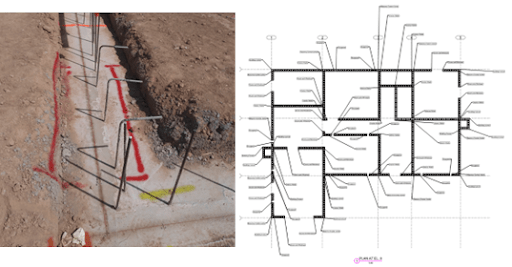

The company’s data-rich Tekla Structures models contain all the information needed for construction. Hobbs Masonry also does all of its rebar drawings in-house. “We issue detailed rebar drawings with elevations as part of our submittal package,” said Hobbs. “A building may have as many as 35 pages of elevations. We never had that level of detail in the past.”

The model also helps ensure everyone involved in the project is in alignment. “We have the owner and architect review the model before we place an order because we’ve come to realize that often, the owner doesn’t completely understand, for example, which finishes the architect has chosen for different areas of the building,” said Hobbs. “With Tekla Structures, we can bring transparency to the process and avoid surprises on the job. When everyone is on the same page, we place our order.”

With the model, it’s easy to avoid costly problems before construction begins. “Every single piece of information that we need to build a job is in the model,” said Hobbs. “We even include detail down to anchor bolts, wood ledgers and PA straps in the model because we want to resolve any issues before workers on the jobsite start to build it. We can identify issues way faster and easier with a Tekla Structures model than we can in the field.”

Often, Hobbs Masonry will send its own surveyor out to the jobsite to verify the points provided by the surveyor of record. “We pull their survey points into our model, and nine times out of 10, we find an issue with layout,” said Hobbs. “It’s much faster to identify problems this way than trying to figure it out with a tape measure.”

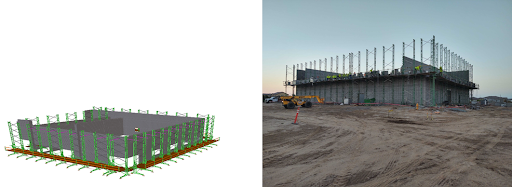

In particular, the Tekla Structures model improves coordination with other trades. Hobbs models concrete footings for every job, even if they’re not executing the work. “We’ve come to realize that if we model the rebar layout and we help the concrete subcontractor with his job, then our work is easier,” he said. “It’s been incredibly beneficial for every job. For example, if the subcontractor misses extra jamb bars or beam bearing locations up above, rework is typically required. The models help us eliminate this rework.”

Models are loaded into Trimble Connect, a collaboration platform that connects the right people to the right information from anywhere and at any time. This ensures that everyone involved in the project can see the big picture, right down to the tiniest detail.

Unexpected Benefits: A Competitive Edge

The move to BIM-M has not only helped Hobbs Masonry work smarter, but it’s also delivered value in unexpected ways. “We worked with a large structural engineering firm a few years ago, and through the process, the engineer received our masonry shop and rebar drawings,” said Hobbs. “The project was successful, and now, that same engineer is working on a new project and knows there will be issues in the job, so she’s asked the contractor for the kind of drawings we provided. In a roundabout way, she’s sending work to us. It’s just another way Tekla Structures and BIM are helping our business succeed and grow.”

The 3D journey is far from over for Hobbs, who is looking forward to diving deeper into BIM. “It wasn’t too long, in the first few months of using Tekla Structures before we realized there’s a huge difference between design models and construction models,” said Hobbs. “I’m convinced that the person building the work needs to build the model. Doing so has already paid dividends for us, and I’m excited about what the future holds.”

About the Author: Guy Erickson is a business manager at Trimble, Structures Division. Trimble is an industrial technology company transforming the way the world works by delivering solutions that enable customers to thrive. Core technologies in positioning, modeling, connectivity and data analytics connect the digital and physical worlds to improve productivity, quality, safety, transparency and sustainability.