Words: Bill Kennedy, Service & Repair Manager at iQ Power Tools

Photos: iQ Power Tools

For more than a decade, iQ Power Tools has taught America’s contractors how to save time and money by eliminating water and silica dust from the jobsite. Bill Kennedy, Service & Repair Manager at iQ, now tells you how to take care of these tools… and how to know them even better.

What is the difference between cleaning a tool and maintaining a tool?

Cleaning a tool is part of tool maintenance, and it should be performed after each use. Cleaning removes any build-up collected from the jobsite allowing for a better visual inspection of the tool itself. It’s advisable to inspect for any damage that may lead to catastrophic failure of a tool. Examples of these may be cracks in the support arm, pinches, and breaks in the power cord.

What are the top five benefits in proper maintenance?

These are, and not necessarily in this order: safety, uptime, efficiency, lifespan of tool and overall dependability!

Proper maintenance ensures the tool’s dependability and safety. Regular checking of the brushes and making sure the blade is dressed or conditioned adds to the dependable performance of the tool. Additionally, performing the “tub drop” test will demonstrate the efficiency of the vacuum and could indicate when the filter requires replacement. To perform the drop test, check to ensure the tub is not overly full, run the vacuum by plugging it directly into an extension cord or turning the saw on, and release the tub as to remove it. The tub should stay up. If it drops, the filter may need replacement or the tub seal may be compromised.

Routine maintenance will always positively impact any power tool’s safety, dependability, lifespan, and value.

Aside from just the main tool itself, talk about the accessories (blades, filters, etc.)

For all iQ Power Tools masonry and tile saws, the blade, filters, and louvres are all integral parts of the cutting system… and thus, are ALL equally important.

The blade is the component that physically engages the tile or paver and performs the cutting. It is important that the blade be matched with the material and be dressed or conditioned. If the blade is not correct or conditioned for the material, it will have difficulty performing the cut and could lose its tension – where the blade will wobble, resulting in a crooked cut.

The filter protects the vacuum motor from damage. It ensures the vacuum motor does not become clogged with particulates in order to maintain proper vacuum power that collects the dust.

The louvres direct the flow of the large particulates into the correct chamber. The centrifugal direction of the blade’s rotation channels the particulates into the louvres and to the correct chamber.

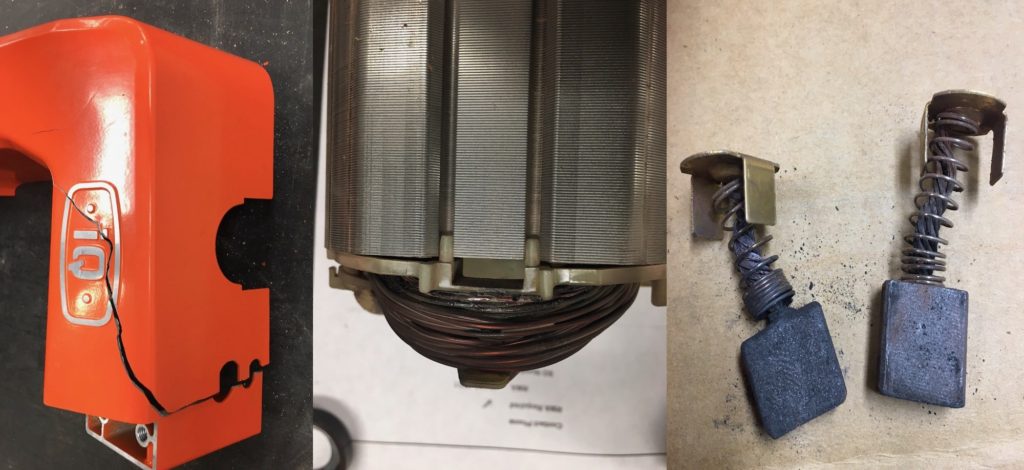

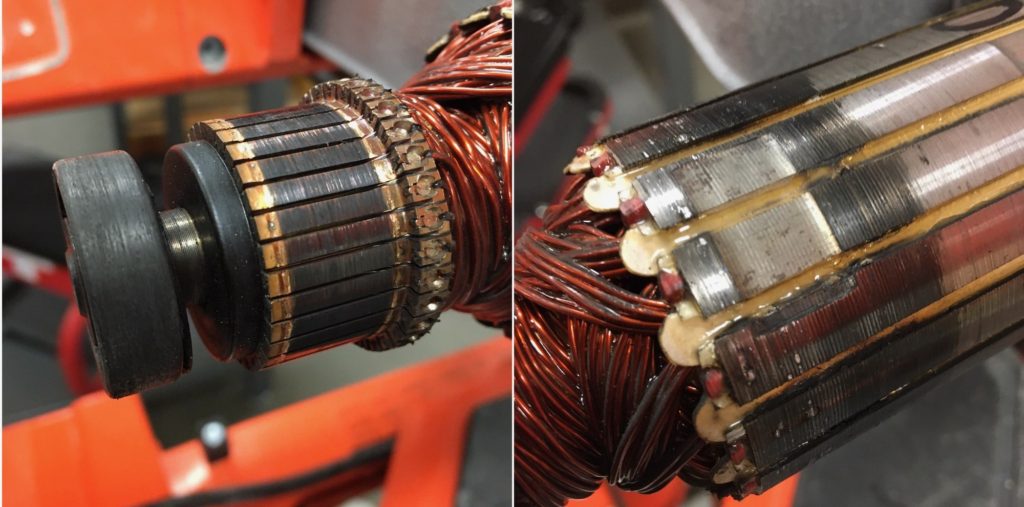

Maintaining motor brushes is one of the most important and simplest maintenance procedures. Regardless of the tool, motor brushes should be inspected at least once a year. As the machine gets used, carbon on the brushes gets worn down. When the carbon is worn completely, the motor cannot work properly because it no longer makes contact with the commutator. Replacing the brushes is a 5-minute/$10 process that can save you hundreds of dollars in future motor repair to ensure the dependability of your saw.

Why is proper storage such an important step?

Proper storing of your tools should be the first and last step of proper maintenance. After using the tool at the end of the day, it should be thoroughly cleaned and inspected. Therefore, at the beginning of the next workday, that tool is ready to go. Storing tools in dry areas is key to preventing any electrical issues. No electric tool should be left outside to risk the chance of moisture damage.

Even with proper care and maintenance, are there other issues that we may want to watch out for?

The best maintenance program cannot always keep our equipment running at their best. Occasionally, other issues do come up with daily use of masonry saws. Normal wear and tear does occur, and you may begin experiencing insufficient cutting power or defective cutting. Then it’s time to check the blade. Are you using the right blade for the material you are cutting? Is the blade dull, blunt, damaged or worn down? If the blade is correct and in perfectly good condition, check to be sure the saw itself is not out of alignment. Perhaps the motor itself needs to be repaired by a technician.

Talk a bit about inspecting iQ tools. What to look for?

There are two types of inspection. Firstly, there is daily inspection prior to use. This level of inspection checks to make sure the tool is ready for use. (Tub is empty, the power cord has no pinches or cracks, rolling table rolls smoothly…etc) And secondly, maintenance inspection should be performed routinely, normally between jobs. A routine maintenance inspection checks the quality of the tool to identify any component needing repair.

Maintain your tools, and your tools will take care of you.