Words: Guy Erickson, Trimble Concrete Segment Business Manager N.A.

Photos: Trimble Solutions

The Problem

What is the problem with construction information? Information is lost as it passes from one person to another for drawings, traditional quantity take-offs, schedules and reports to communicate project progress. For example, when we study a set of drawings, it does not enhance your understanding of the project, it only enhances your understanding of the drawings.

Design software today does not address every need for masonry construction and is not completely derived from the model information. The simple reason is the design model does not reflect what is being constructed in the field. Without a constructible model, you are losing the flow of information throughout various stages of the project, limiting model information exchange and coordination between various project stakeholders.

With a model built in Trimble’s Tekla software, project stakeholder’s shared understanding of the project continuously builds over time. Any enhancements to the model improves our collective understanding because we can access information quickly and easily. The model becomes the place where all information is stored at every stage of the project.

Our Solution and How We Got Started with Masonry Tools

Tekla Structures is a purpose-built tool specifically engineered for the construction industry, with an emphasis on constructability. Tekla is used by a wide variety of disciplines in the concrete industry including mason contractors, self-perform GCs, rebar detailers, and formwork manufacturers. The demand for masonry tools comes directly from industry professionals who were struggling with design tools. In most cases the design programs were not meant for construction level detail with issues in the areas of file size limitations, modeling speed, and interoperability.

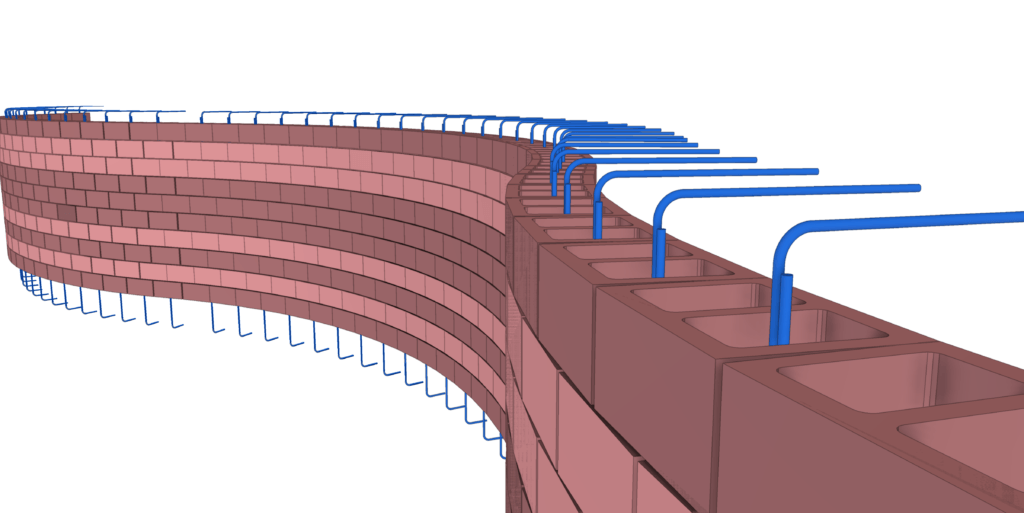

The contractor can have every block, all reinforcement and, connection detail in the Tekla model- we created simple to use tools to produce this high level of detail. Our team worked with mason contractors, organizations, and industry professionals to build tools specific to the masonry trade. Fred Kinnetader, on behalf of BIM form, was instrumental in guiding our development and with introductions to industry pros, like his son Mike of KMI Construction. We also branched out to work with other mason contractors and Self Perform GC’s during the development period.

Mason contractors are using Tekla to develop highly detailed masonry models to extract product information and material counts, run clash-detection, and produce shop drawings directly from the Tekla model. Not all contractors use Tekla alike, as the functionality extends to scheduling, logistics, site layout, rendering capabilities and live-status sharing of information to field tablet devices, and robotic total stations.

Earlier this year, Trimble partnered with MCAA to conduct a webinar where we asked “where would constructible BIM help you most?” Forty percent of those responding answered “field coordination,” in order to avoid construction conflicts. Not having a constructible masonry model will always leave open the possibility for error or conflicts without the correct project planning.

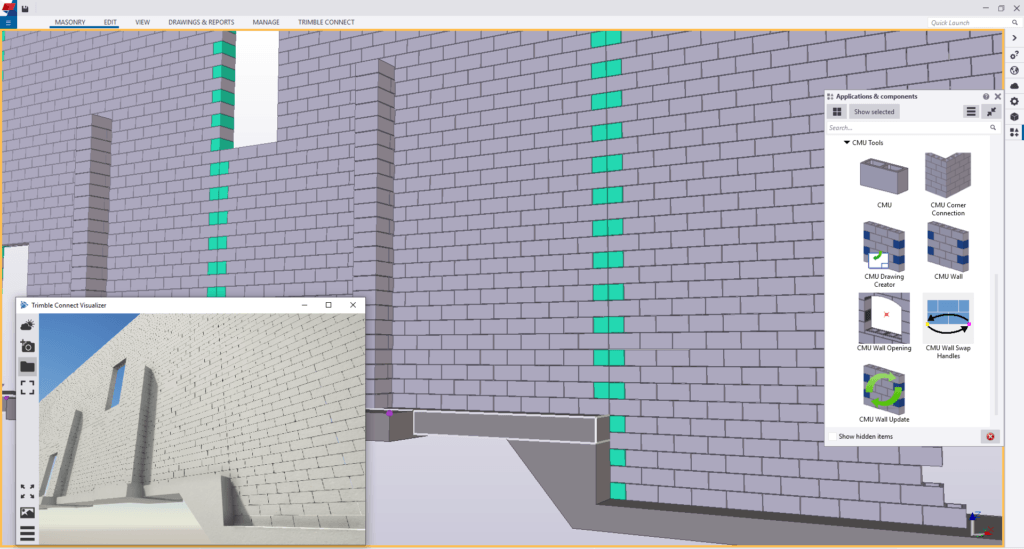

About CMU Tools

In June of 2017, Tekla Structures first released masonry tools which featured: placing walls with a specific block type, specific conditions for corner, and applicable openings. Though there are no limitations of what you can model in Tekla, customer feedback is critical to enhancing our available options. Trimble is on the third version, and now includes adding specific coursing, bond beams, horizontal and vertical reinforcement, and tools to quickly create shop drawings.

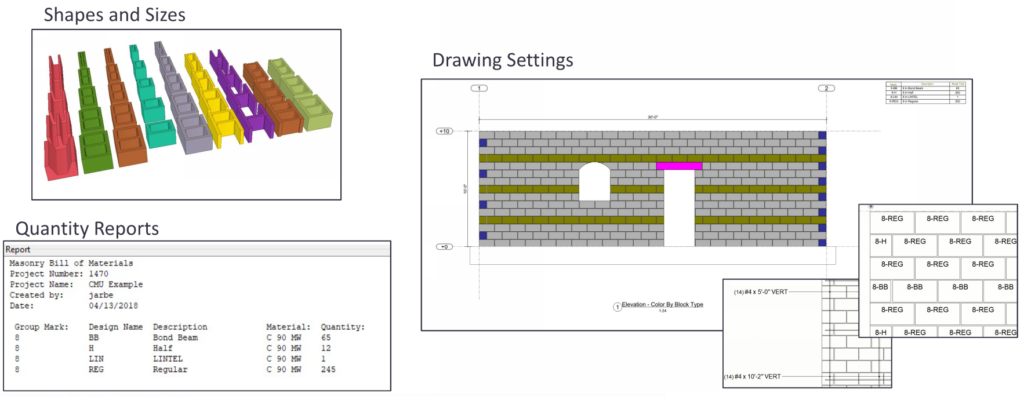

The most frequent request has been calculating grout for reinforced blocks, which is now available. When rebar is placed into the walls the system can automatically mark blocks to be grouted, which can be shown in a drawing or bill of materials. Another popular improvement is the added ability to transfer an architect’s model into individual masonry blocks. Typically when an architect’s model is exported, the model does not include individual unique blocks. The walls appear to be a single element with a width, height and thickness appearing more like a concrete wall. Now with only a couple clicks, this geometry can be converted to individual blocks and reduce the amount of re-work.

Besides quickly building tools to create project specific masonry models, we focus a large effort on localization which specifies our product for the North American market. This will include block sizes (4”, 6”, 8”, 10”, 12”), block shapes (bullnose, open-ended, half, etc.), drawing settings, and reports ready to go out of the box or located on our Tekla Warehouse in the Cloud.

Tekla Warehouse goes far beyond masonry tools to include applications, custom tools, shapes, and settings for Tekla Structures. Tekla Warehouse provides a centralized access to this content that can now be taken into use in a streamlined way, and the content is constantly increasing. Manufacturers can make their products and applications available to users, who can take the exact 3D product models straight into their Tekla models.

Start in Estimation

If you ask any contractor how they are utilizing Tekla, whether it be concrete or mason contractors, the answer will never be the same. Tekla is utilized specifically for how your business operates and what areas you need to benefit from or improve. Tekla has a built-in Quantity Take-Off tool that organizes all the objects in the model. The Tekla organizer is very flexible and completely customizable for our customer’s needs.

A typical workflow would start out the model in estimation. A PDF is brought into the model to snap to the structure points to place masonry blocks. Alternatively, you can import an architect or engineers’ model, which can be transferred into native Tekla parts that can be modified and adjusted.

2D takeoff is greatly improved. The amount of clicks for a model estimate can be comparable to the number of clicks producing a Tekla model, and in many cases faster. In Tekla, you now have a 3D model built with the estimate, and can continue to add project benefits like coordination or layout downstream. The greatest benefits come from the quantities. Let’s look at this word specifically: “estimate.” If we were to take this word literally, other replacement names or phrases would be “roughly calculate”, “approximate” and “guess,” to name a few. Tekla takes the guesswork out of your estimate. You are providing exact quantities based on the PDF document or model you’ve received resulting in competitive bids. Not only will you have a competitive bid, but also a 3D model for sales presentation.

Not every job estimated is awarded, of course, but for the ones that are, you get to carry that information on to the next stage of the project. The information continues to build as you enter the planning and coordination stages. At this point the model can be “tightened up” or adjusted based on design changes, drawings can be produced, and material quantities are automatically updated.

The Tekla masonry tool can place walls with various patterns, shapes, colors along with multiple layers of structural masonry, air barriers, brick veneer, etc.

Tekla has the ability to bring in software-developed components from other programs. This is a common way of inserting individual blocks a company has created prior to using Tekla. Custom tools specific to your needs can also be created inside of Tekla Structures without programming knowledge. These tools are referred to as “Custom Components,” which can create unique conditions such as pilasters, unique corner conditions, and wall penetrations. Custom components are not necessary to use Tekla, but can save time as you go to the next project since they can be saved to be used by every user in the organization and every future model.

Taking Information to the Field

The sharing of information does not stop with the drawings sent to the project site. Tekla Structures can import and export site layout point data to and from the model. The model can be exported to owners or other project stakeholders through Trimble Connect. This is a great way to communicate live project conditions. Trimble Connect can be used in the Cloud, on a desktop computer, or on phones or tablets in the field.

Site Layout points can be added using tools for our Tekla Warehouse or placed manually at specific points useful for the field. The points are placed as a visible object in the model, and will contain the necessary real-world coordinates for total stations. The layout manager is a software holistic tool, allowing you to connect to Trimble Robotic Total Stations or other hardware manufacturers.

We would like to hear from other industry professionals about their experiences with Constructible BIM for Masonry and welcome any Trimble product interests.