Words: Amy Lamb Woods, P.E., Director of Technical Education, International Masonry Institute, and Casey Weisdock, Director of Technical Education, International Masonry Institute

Introduction

Historic masonry buildings have common issues that architects, engineers, conservators, contractors, and owners are often challenged with evaluating and addressing. Historic generally refers to buildings 50 years of age or greater with significance architecturally or culturally. For this older building stock to continue being relevant in the modern era, modifications and upgrades are needed. This may change how the historic masonry enclosure functions. Thoughtfully and appropriately designed restoration projects can preserve the integrity of the masonry building and continue its life for future decades. With greater knowledge of historic masonry material properties, wall systems, condition assessments, and best practices for repair and restoration, design and construction professionals can successfully develop and implement

Historic Masonry Materials

Historic masonry materials primarily refer to brick, terra cotta, stone, concrete block, cast stone, and secondarily, mortar. In a typical masonry wall assembly, mortar might comprise 20 to 25 percent of the masonry wall system. Masonry materials are good in compression, and generally poor in tension unless reinforced. Their strength and porosity vary for each type of material as well as within each type. It is important to understandthe common characteristics specific to eachmasonry material such as strength, porosity/ density, water absorption, composition, type and gradation of aggregates, and cementitious material used, when developing treatments.

Masonry Wall Systems

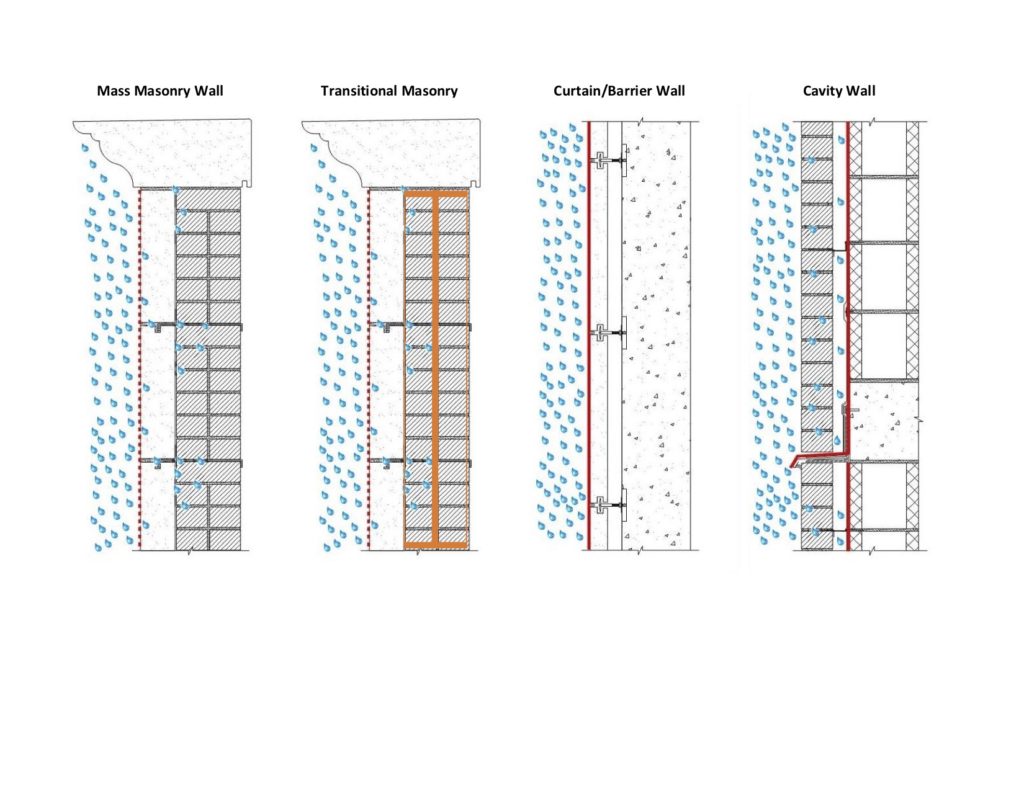

Exterior masonry wall systems have evolved through centuries of experimentation and more recently by way of a rapidly changing construction industry. Historic systems primarily fall within the following categories: mass, transitional, curtain/ barrier, and cavity. Additional elements that are integrated with these masonry wall systems include, but are not limited to, metal ties, iron and steel anchors, steel lintels, steel structural elements, flashings, and sealants. Each wall system has different elements that contribute to how the wall moves, manages water, and holistically functions with the various types of masonry materials. Descriptions are included below for the primary historic masonry wall systems and how they manage water illustrated.

Exterior masonry wall systems have evolved through centuries of experimentation and more recently by way of a rapidly changing construction industry. Historic systems primarily fall within the following categories: mass, transitional, curtain/barrier, and cavity. Additional elements that are integrated with these masonry wall systems include, but are not limited to, metal ties, iron and steel anchors, steel lintels, steel structural elements, flashings, and sealants. Each wall system has different elements that contribute to how the wall moves, manages water, and holistically functions with the various types of masonry materials (Figure 3). Descriptions are included below for the primary historic masonry wall systems.

Mass

Mass masonry wall systems are the oldest typology, are based on empirical design, and have a track record of lasting thousands of years. Masonry materials used in these systems are typically stone and brick but can also include ornamental terra cotta or cast stone. Mass walls are load bearing and act as the main structure of the building. Floors, roofs, and interior columns can be wood timber, steel, or stone and brick masonry.

There are many examples in the world dating back thousands of years up through the 20th Century that

Mass masonry exterior walls tend to move as

Transitional

Transitional masonry wall assemblies represent a period of construction between the 1890s and World War II, in which the building industry was “transitioning” from mass walls to steel skeleton frame construction. As the desire to construct taller buildings increased, and the use of elevators were introduced, mass walls became an ineffective building strategy. The thickness of the mass wall necessary to carry load reduced the space allowable for window openings and therefore, light and ventilation. These walls also reduced sizeable usable interior space, especially at the base of buildings. To provide adequatestructure as well as increase floor plan spaceand window openings, steel became the popular solution. Transitional masonry wall systems are a hybrid of masonry and steel but are not considered curtain or barrier wall systems.

Integrating steel within mass masonry buildings started by using elements of

Mass masonry and transitional masonry wall

Curtain/Barrier

Curtain wall systems, also referred to as barrier wall systems, utilize masonry as an exterior cladding system only. The main building structure is often steel or concrete. Masonry cladding is tied to the structure and uses shelf angles and ties for the gravity and lateral loads of the masonry units. This is a common type of construction for buildings that are clad with terra cotta and dimensional (thin) stone veneers.

Similar to transitional masonry wall systems, curtain/barrier walls also typically had little to no accommodation for movement of different materials and did not include movement joints or isolation materials between masonry and steel. Additionally, there was no internal system for managing water. The design of these systems often wrongly assumed that the exterior facade acts as a barrier, preventing water from penetrating the wall system. In reality, if waterinfiltrates the exterior surface, there is no way toweep it out of the wall system.

Cavity

Masonry cavity walls evolved from the understanding that some residual water will likely penetrate the masonry cladding system. This typology is designed to manage water between the exterior masonry cladding and the main structure. The main structure can be steel, concrete, or concrete masonry unit (CMU) withan infill backup material such as concrete orCMU. Lateral ties and shelf angles are used to support the exterior cladding system.

Water is managed by including an air space between the exterior masonry cladding and main

Condition Assessment

Conducting a complete building condition assessment is critical for determining the cause of problems and the extent of damage. This approach also helps in understanding the original design/function of the building versus how it might be used in the future based on new programming needs. Assessments include background research, investigation, testing, and developing treatment options.

Background

Background information such as construction, repair, and maintenance history of a building provides

Investigation

The investigation of a building allows for a holistic approach in diagnosing any issues, which begins with a walk around the building and roof areas. Elevation drawings should be used or developed to document visual observations throughout the facades and roofs. The most vulnerable locations on a building are horizontal surfaces such as parapets and window sills, projections such as cornices and belt courses, and any other skyward facing surfaces. If damage or breaches are found on horizontal surfaces, it is certain that water hasor will directly infiltrate into the wall system.Corners are also susceptible areas of a building due to the lack of movement joints and higher stress concentrations.

It is imperative to look close-up at the horizontal surfaces and identify locations on each representative area of the facades. Close-up observations should be conducted in combination with sounding of the surface for any hidden defects or delaminations. The tool used for sounding will depend on the masonry material (e.g. rubber mallet for terra cotta or metal hammer for hard stone). Additional poking and prodding tools may also be needed to evaluate the materials.

An investigation should also include exploratory openings to limit unwanted surprises during the restoration work. Openings are typically done with a qualified masonry restoration contractor where removal of the exterior materials is done carefully. Openings allow the engineer or architect conducting the assessment to document the construction and material details and compare them to any drawings or previous assumptions.

Testing

Both field and laboratory testing may be neededto fully understand the root cause of deteriorationor water infiltration of the facades. Field testingmay be non-destructive or destructive. Non-de- structive evaluation (NDE) using various types of equipment is often helpful in determining location and size of anchors or reinforcing. Invasive in situtesting can include flat-jack testing of brick, watertesting, or adhesion testing.

Where additional information about the masonry materials is needed, samples should be removed in discrete but representative locations. Laboratory testing may include compression, tension, flexural, absorption, porosity/density, bond,

Treatment Options

Information collected and documented during the background research, field investigation, and testing

Common Deterioration

Masonry materials are typically strong in compression, however can be susceptible to tensile stresses, therefore the damage that is commonly observed is cracking, spalling (a hand- sized chunk of material missing), or scaling (thin outer surface missing). Some common deterioration tendencies are listed herein.

Water infiltration is the most common source of deterioration especially in the case of mass, transitional, and curtain/barrier wall systems that were not designed with water management systems or

Other causes of deterioration can include previous inappropriate treatments that cause cracking and spalling or entrapment of moisture in the materials. A spall repair, replacement material, or pointing mortar that is denser and stronger than the original can damage the adjacent original materials by both trapping moisture and not allowing vapor transmission and differential movement. Similarly, applying a coating or sealer can also change the breathability of the masonry materials and more importantly, the mortar, leading to moisture entrapment and damage to the masonry system.

Because water is more likely to infiltrate on horizontal surfaces than vertical surfaces, areas that are vulnerable to deterioration include parapets, cornices, belt courses, window sills, and balconies. Hidden horizontal surfaces are also more susceptible to holding infiltrated water, including steel lintels, shelf angles, and steel beam flanges. In all cases, water infiltration leads to deterioration and damage

Repair and Restoration Options

Once a condition assessment is complete, the masonry system and materials are known, any needed temporary stabilization has been installed for imminent hazards, and the project

Protect Horizontal Surfaces

Assuming the roof and its details have been evaluated and are watertight, the first and most

- Sealant installed with backer rod to prepared, clean, and primed substrates of the horizontal facing mortar joints. The sealant can be wrapped down the face of the vertical joint a small amount depending on the detail. Silicone sealant would be expected to have a useful life of up to 10 years. Since the joint is so critical, it is not recommended to leave it for the full expected warrantee; instead, annual assessments for debonding or breaches should be conducted.

- Silicone sheet installed as added protection over a newly installed sealant joint. Make sure the silicone sheet and silicone joint materials are compatible and bond.

- Lead T-joint cap installed as added protection over a newly installed sealant joint.

- Sheet Metal installed for additional long-term protection. Material options are copper, tin-zinc alloy copper, stainless steel, painted galvanized, and anodized aluminum sheet metal copings/flashings. The new assembly should provide slope, integration with waterproofing membranes, expansion details for the length of the run, an appropriate reglet/transition joint to the vertical leg, and a drip edge. Depending on the material chosen, this solution can last from 40 to 100 years. It is non-reversible, and anchors and membranes will affect the original materials, but these solutions also provide a high level of protection and resiliency to the masonry facade.

- Reinforced Liquid Applied Roof Membrane applied, and is often helpful when there are non-linear conditions, such as cornices with ornamentation and curves. Preparation of the surface, proper installation of the layers and reinforcement, as well as

an ultra violettop coat should be installed per manufacturer’s directions. Thetop coat can - be matched to the masonry material. This solution is non-reversible due to the preparation work on the top surface prior to installation of the membrane.

- Reinforced Liquid Applied Roof Membrane applied, and is often helpful when there are non-linear conditions, such as cornices with ornamentation and curves (Figure 7). Preparation of the surface, proper installation of the layers and reinforcement, as well as

an ultra violettop coat should be installed per manufacturer’s directions. Thetop coat can be matched to the masonry material. This solution is non-reversible due to the preparation work on the top surface prior toinstallation of the membrane.

- Through-Wall Sheet Metal installed where details, specifically at coping units, can be removed and reinstalled to install through-wall sheet metal. This is an excellent 50 to 100-year long-term solution that is less visible. Most commonly, stainless steel or copper is used, which is integrated with waterproofing membranes, expansion details, and drip edges (Figure 8). Anchors for the coping units will need to be integrated with this solution to make sure that penetrations are detailed to be watertight. This does not necessarily mean just sealant, but a solution that has been installed as a mockup and water tested to confirm the solution will not leak. After the coping units are reinstalled, one of the joint sealant details should also be installed to protect the system.

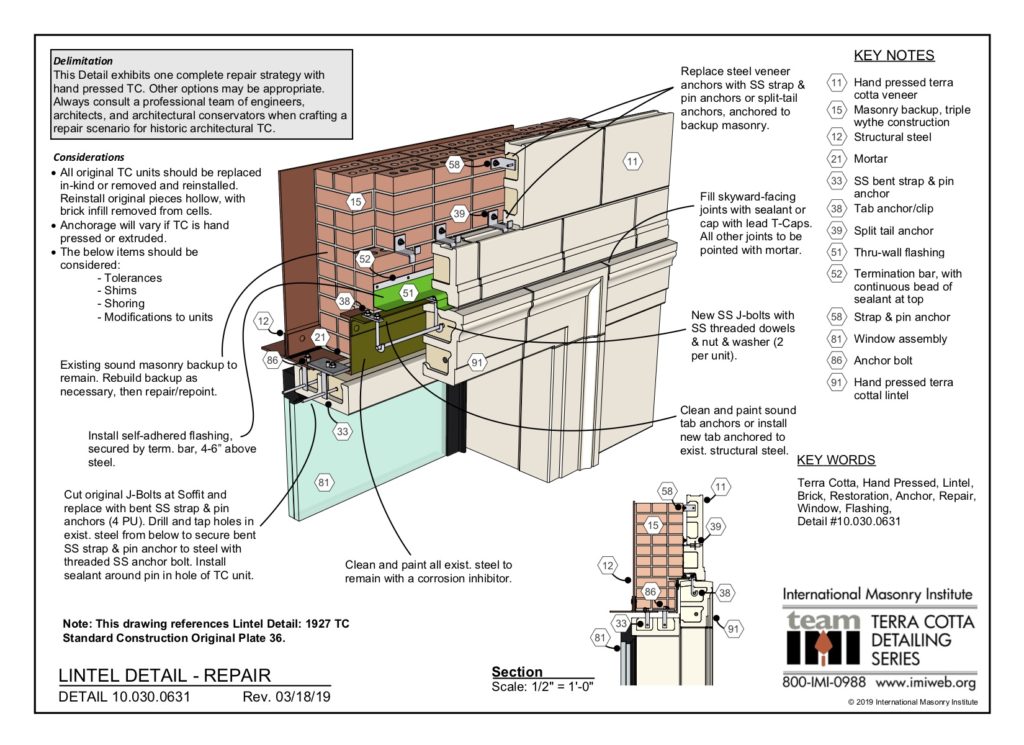

Masonry System Repairs

The repair of masonry systems includes repairing, replacing, or coating exposed corroded steel elements, integrating new water management flashings, and adding supplemental anchorage. One or more of the following may be needed for the project:

- Corroded Steel – Remove masonry to expose corroded steel elements. Assess the condition of the steel to determine if it needs to be replaced or repaired. To add protection to the steel, clean and coat it with a corrosion inhibiting coating system in accordance with manufacturer’s directions. An alternative

- Water Management Flashings – Remove masonry to expose horizontal steel elements that are contributing to holding water. This is common with transitional masonry building details. Install a new stainless-steel flashing system that includes a mechanically fastened termination bar, slope, end dams, drip edge, and mesh weeps.

- Supplemental Anchorage – Where additional supplemental anchorage is needed for the masonry facade to improve lateral support, there are stainless steel options including helical, expansion, threaded rod set in epoxy, and grout tube. Not all are appropriate for each type of masonry and the selection should be carefully chosen based on material and conditions observed. Mockups and pull testing of the masonry material and the backup system should be conducted to ensure the use of appropriate anchors.

Masonry & Mortar Material Repairs

The two primary methods of repairs include replacing masonry units and/or patching original units with cementitious repair materials. Methoddetermination is based on conditions identified, budget and schedule for the project, and project goals and durability expectations. In either case, the most important criteria

Matching is critical so that the new materials do not cause unexpected future damage. If

It should also be noted that new materials are often different from historic materials. Cement and cementitious materials undergo higher kiln temperatures and are typically ground more finely, which can lead to stronger and denser mixtures. This is specifically important for cast

Qualified Masons

Historic masonry restoration projects are successful when qualified craftworkers are included within the project team. The International Masonry Institute (IMI) offers a six-day HistoricMasonry Preservation Certificate (HMPC) course for journey-level masonry restoration contractors with the International Union of Bricklayers and Allied Craftworkers. The program was developed to provide a

Conclusion

Historic masonry buildings are durable and longstanding; restoring, repairing,

Resources

IMI provides training, education, and resources that focus on creating high-quality restoration