Words: Nichole Reber

Photos: BanksPhotos

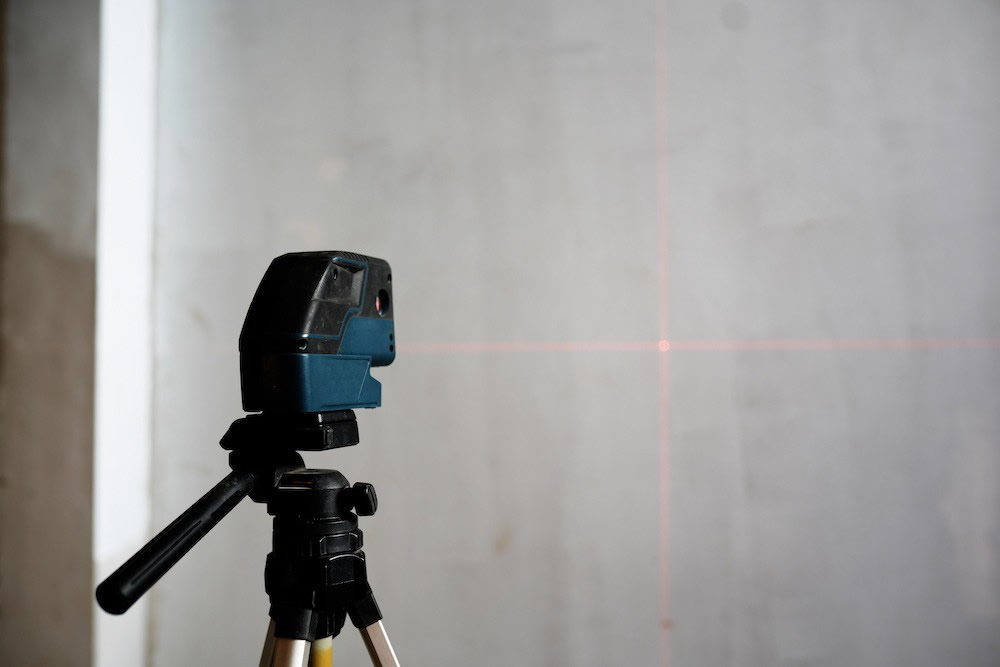

Laser levels have been around for a few years, and they seem to keep getting better and better. For indoors or outdoors, in bright or low light, and large or small projects, there is a laser level to suit anyone’s needs. What’s more, they serve more purposes than you might think.

Laser levels are used for leveling and aligning vertical, horizontal, square, angle, grading-slope and point-transferring applications. Some trades use line laser levels for installing drywall, HVAC systems, ceiling joists, sprinklers, flooring, and aligning rafters, doors and windows. We use them for aligning plumbing walls and metal studs. As Masonry magazine mentioned in last year’s article on the topic, for taller walls, laser levels help maintain plumb walls with vertical applications. They also help ensure laid block and brick is level, and buildings or projects remain symmetrical or square.

Laser levels project along the horizontal and/or vertical axis, enabling you to align your work with red or green fixed lines, dots, or a combination of lines and dots. A true sign of laser levels’ evolution is their new laser color. The color, after all, significantly influences its effectiveness and makes or breaks your relationship with laser levels.

“If there’s a lot of sunlight in the area you’re working in, that will wash away the laser line,” says Bosch’s Product Manager, Jordan Majstorovic. “The green beam lasers are going to give you a stronger, more visible line in those conditions, as opposed to the red beam products.”

Today’s laser levels are often available in green, a far more visible color than red. Green lasers may drain more battery power than their less visible counterparts but they are becoming increasingly popular, which means their price is going down.

Three types

Of the three main categories, the fixed laser level are the most basic. These feature a laser diode attached to a bubble level that serves as a pointer. They work best at close range on small projects.

Another type is more advanced: self-leveling lasers. These emit leveled or vertical lines and dots. They work well for projects with areas of 60 to 100 feet. They also offer much higher accuracy than fixed laser levels. In fact, some models can reach an accuracy of ±0.0002″/1″.

The third type of laser level is the rotary laser level. These are typically positioned in the center of the jobsite and, because they turn, they can project a laser beam 360 degrees around the job site. Their ability to slope the line makes them suitable for outdoor jobs. You can almost double the range when you use one in conjunction with a detector, which detects laser beams in and beyond the spectrum visible to the human eye. Plus, when used with a detector, which picks up the laser at distances our human eyes can no longer see them, rotary lasers have a range of up to 700 feet.

Debunking the myths

Misconceptions still abound throughout the industry about what laser levels do and do not do. Majstorovic addresses some of them. One of the biggest misconceptions is that they are hard to use, he says. Bosch laser levels are self-leveling. In fact, there’s no set-up, no need to make sure your lines are level: the tool does it for you. Turn on the tool, set it down, and let it level itself.

Dustin Prevete, group product manager at Dewalt, acknowledges the misconception that laser levels are accurate only at short distances. “Stated accuracies are always at a given distance,” he says. As that standard or given distance increases, that level’s accuracy also grows. The standard for line levels is a 1/8-inch accuracy at 30 ft and 1/8-inch at 100 feet for rotaries. “As you get past 30 foot or 100 foot initial thresholds, the accuracy variance grows,” Prevete says. Accuracy differs per model and brand he warns.

Another point of concern is less of a misconception, more of an intimidation factor. It has to do with buttons. The truth is that yes, some laser levels have a lot of buttons. That can definitely be intimidating. The market has introduced a number of models lately with fewer buttons and an interface that makes using the product and a little more self-explanatory. Experts agree that the best way to find the one that works for you is to go have fun exploring the range of models and brands available and ask at your favorite shop or website.

Do you imagine these newfangled things are difficult to learn or complicated to use? There may indeed be a bit of a learning curve with some models, but Majstorovic says most of Bosch’s models are really quite intuitive.

“You turn the laser on and off with a simple switch, and then pressing another button lets you choose which line configuration to project: a horizontal or vertical line,” he says. He gives an example of using the horizontal line to do some leveling for an installation of a wall or cabinet. The laser will project a horizontal line that is level. The user can then work off that line to level out a four-foot masonry wall, for instance, or to make sure a cabinet goes in perfectly level.

“If you’re building a wall, this laser could be used to project a line on the floor, and then you can use that line to make sure that your wall is going straight along the floor,” he explains. “This is going to give you that horizontal benchmark to work off of to make sure everything is level.”

Accessories too?

Accessories add an additional layer of ease and optimize today’s laser levels. Improved technology with laser levels means they don’t require perfect environmental conditions. They can overcome various hurdles with the help of a number of devices. A detector or reader, is one of them. Detectors can penetrate low light, fog, dusty air, or other conditions that render the laser light invisible. This staying-power makes laser levels more useful when working outdoors.

Now let’s consider mounting accessories. These include light-weight or heavy-duty tripods and brackets and poles. Tripods, of course, enhance stability and optimize a level’s versatility among diverse landscapes. A tripod base stabilizes some poles. Other poles are pressed against the ceiling for stability. Poles are used indoors and allow a user to quickly and easily shift the level among various heights. Brackets are also used for more localized laser level mounting.

Before You Buy

DeWalt’s Prevete offers some tips to buy what you need.

- For whichever laser level you choose, make sure you have a compatible detector. Some come with the levels, others are an add-on. Like an extra set of eyes with power beyond the human eye, they multiply a level’s usefulness.

- Double check that the level’s stated accuracy and ranges suit your needs.

- Understand the Ingress Protection (IP) rating. This is a durability factor. The IP rating tells you how well the level handles drops and how water- and dust-resistant it is.

“We tout IP65 on our line, spot, and combo lasers, and IP67 on our rotary lasers,” Prevete says. “That (means they) can stand up to the beating that (they) would take outdoors. When used on concrete, a good drop rating is also important. Our line and spot and rotary lasers carry a two-meter drop.”

4) Make sure the laser level is calibrated before undertaking any job— especially large jobs where the smallest inaccuracies can lead to the biggest errors, adding unforeseen labor and material costs.

DeWalt’s 20V MAX Tool Connect Tough Rotary Laser has an IP67 debris/water resistance, two-meter-drop protection and a green or red beam. They’re rugged enough for adverse jobsite conditions and are accurate to within 1/16” at 100 feet. They have an interior range of 250 feet or an exterior range of 2,000 feet. They come with a detector, a ceiling bracket, laser enhancement glasses, target card, and remote control. Their biggest accessory features are the technology built inside, such as the Tool Connect app, which helps track its whereabouts.

“When you think about how expensive some of these things are, the ability to always know where it is on the job site can be very beneficial,” says Prevete. “It tells you if that laser has taken a fall, and if that fall has jostled it to the point where you have to check calibration.”

Other technological tools allow you to expand the length of working range. For outside projects or projects in large spaces, certain Bluetooth-enabled features allow you to manipulate and control the laser, expanding a working length from 50 to 100 feet or more. Some DeWalt models have a Bluetooth-enabled feature that tells the detector to work as a relay.

“That extends that remote capability all the way up to one thousand feet away from the rotary, almost twenty times what you’d get out of a traditional IR remote,” Prevete says. “That’s in addition to all of the other things like the tool tracking, drop notifications, and the digital display or digital control panel on your phone.”

Maintenance

Once you have committed to a laser level and bring it back to the job site, you want to take good care of

it. To ensure your new gadget gives exceptionally precise horizontal and vertical lines long into the future, a little common sense maintenance helps. Majstorovic has some suggestions:

- Don’t throw it around. That’s one of the quickest ways to throw the level out of calibration. Bosch’s and many other manufacturers’ levels have a pendulum lock to sustain the calibration. Regardless of whether you have pendulum lock, it’s a very good practice to check your level’s accuracy before starting any job. Take it to the manufacturer’s service center for calibration if required.

- Use the level’s carrying cases and the accessories’ pouches provided by the manufacturer. This helps keep it clean inside and out.

Whether you’re new to laser levels, you’re expanding your assets, or you’re upgrading to the latest model, these tools can optimize your crew’s efforts and add new dimensions of effectiveness and possibility.

Fixed, self-leveling, and rotary laser levels all have common benefits, but they do vary and will optimize tasks best if you buy one according to your true needs. That is, don’t regret buying one that works better for large or outdoor projects if most of your projects are small or indoors. Talk to other crews, other subs, or service pros to see if the level you’re interested in works well in rainy, dark, or overly bright conditions, or if you need an accessory to help.

Laser levels are helping crews from coast-to-coast to optimize their masonry efforts. The prices are going down while the number of benefits go up. So, having set aside some misconceptions and have been shown how they save time and labor, what are your thoughts? Share with us on Facebook or @MasonryMagazine.