Words: Jan Boyer, Executive Director, Cast Stone Institute

All photos courtesy of the Cast Stone Institute ®

The Cast Stone Institute ® (CSI) is the recognized industry authority for architectural cast stone – providing expert counsel to the architectural, engineering and mason communities. Recently CSI Technical Committee and Board of Directors undertook the detailed task of reviewing all of the CSI Technical Bulletins. This massive project is completed and the updated Bulletins are on the CSI website. The following information is a synopsis of the Technical Bulletins that are featured on the website that are important for masons to be aware of when working on architectural cast stone projects.

Before getting into the specific Technical Bulletins, it is important to understand that architectural cast stone is specified, fabricated and installed under legal reference standards documents and not just CSI industry standards.

PRIMARY REFERENCE DOCUMENTS

ASTM C1364-18 Standard Specification for Architectural Cast Stone

This is the master document for architectural cast stone and a legally binding ASTM document. All other technical documents are based on this ASTM standard. It can be purchased directly through the ASTM website at www.astm.org.

TMS 404-504-604

Architectural Cast Stone Standards were developed through The Masonry Society TMS 404 – 504 – 604 for Design, Fabrication and Installation in one standards publication. These new standard were finalized in October 2016 and adopted into the 2018 version of the International Building Code. They are the first ANSI certified standards to address design, fabrication and installation in one document making it very easy to determine proper installation procedures as well as who is responsible for what part on a project. This document can be purchased through The Masonry Society at https://masonrysociety.org/product/tms-0404-16/

Cast Stone Institute Specification 047200 –

Architectural Cast Stone is specified under Masterspec 04720. The Cast Stone Institute maintains the definitive version of the standard specification which is constantly kept up to date. It is available for free download at www.caststone.org/specifications.htm

Cast Stone Institute Technical Bulletins

There are numerous Technical Bulletins on website for free download. http://www.caststone.org/bulletins.htm

CAST STONE INSTITUTE TECHNICAL BULLETINS

The following is a snapshot of each of the Bulletins that relate to what masons may need to know and a reference to the Technical Bulletin number for each.

MORTARS FOR CAST STONE INSTALLATION Technical Bulletin #42

Selecting the appropriate type of mortar for setting cast stone is perhaps the most important factor in the performance of a masonry wall. The mortar must have sufficient strength, be durable, resist rain penetration as much as possible and yet be flexible enough to accommodate slight movement within the wall assembly. As noted in TMS 604-16, Standard Specification for Installation of Architectural Cast Stone, mortars used in the setting of cast stone should meet the requirements of ASTM C270, Type N mortars.

Included in this Bulletin is information on proper mortar mixing, wetting head and bed joints, the proper specification of mortar/pointed joints and sealant joints, raking and pointing of joints, lug sills, selection of joint types, and more.

SEALANT JOINTS Technical Bulletin #43

The decision to use a mortar or sealant joint can impact the success of the masonry project so this bulletin provides guidelines to assist in this determination. In general, all cast stone sections with projecting profiles, exposed top joints or rigid suspension connections to the supporting structure should be “soft” sealant joints. Sealant systems are not intended to bear weight, so plastic setting pads or lead shims are required when setting the cast stones. Thermal and other movement should be considered by the design engineer.

POINTING OF JOINTS Technical Bulletin #44

Tooled mortar joints are best suited for masonry-bound trim items such as belt courses, lintels, window surrounds, date stones, inscription blocks, quoins, keystones and similar applications. The mortar must be raked out of the joint to a minimum depth of 3/4 inch of the face joint material. A concave joint is recommended for the best protection against leakage. Pointing mortar should be softer than the stone so that thermal stress will not cause spalling at the edges of the joints. Coloring may be added to achieve almost any hue however possible cast stone staining may occur. Always specify a mockup wall when approving final colors and be sure that it has been properly cleaned because cleaning will usually affect the color of pigmented masonry materials.

FLASHING, WEEP HOLES AND RELATED ANCHORAGE Technical Bulletin #47

This eight page bulletin details recommendations on design of a drainage/cavity wall – flashing at bases, over openings, at coping and caps — anchor penetrations through flashing – flashing materials. It also highlights several pages of detail drawings for typical connections for anchoring and flashing details including anchor straps, split tail anchors, dowel pins, typical anchorage at a cornice, and field cur reglet.

USE OF REINFORCEMENT Reference Technical Bulletin #51

Cast stone is an architectural element and should not be used to support the building structure or load bearing elements, yet a structural engineer should design reinforcement for structural or unusual situations. Requirements of the reinforcing material as well as guidelines for the possible use and placement of the reinforcing are outlined in this bulletin. In general, steel should be added to the design only when necessary for safe handling, setting and structural stress.

One important misconception about reinforcement in concrete is that it will prevent cracking, but reinforcing steel will only serve to control cracking from extending and limiting its width. No amount of conventional reinforcing will reduce the likelihood of cracking when units are designed excessively long and thin. To prevent cracking the Cast Stone Institute suggests that designers consult with the manufacturer before drawing units that exceed fifteen (15) times their average effective thickness. Units less than 24 inches (600mm) in both length and width dimensions shall be non-reinforced unless otherwise specified. Units greater than 24 inches (600mm) in one direction shall be reinforced in that direction.

ALLOWING FOR MOVEMENT OF MASONRY MATERIALS Technical Bulletin #52

Various building materials, brick, block and cast stone experience dimensional changes and movement differently on the wall. If this movement is restrained, cracking may result therefore movement joints are used. This bulletin explains the impacts of thermal movements, moisture movements, drying shrinkage, different materials horizontal joint reinforcement. Recommendations for joint placement, crack control, linear shrinkage and curing of units are included in this bulletin.

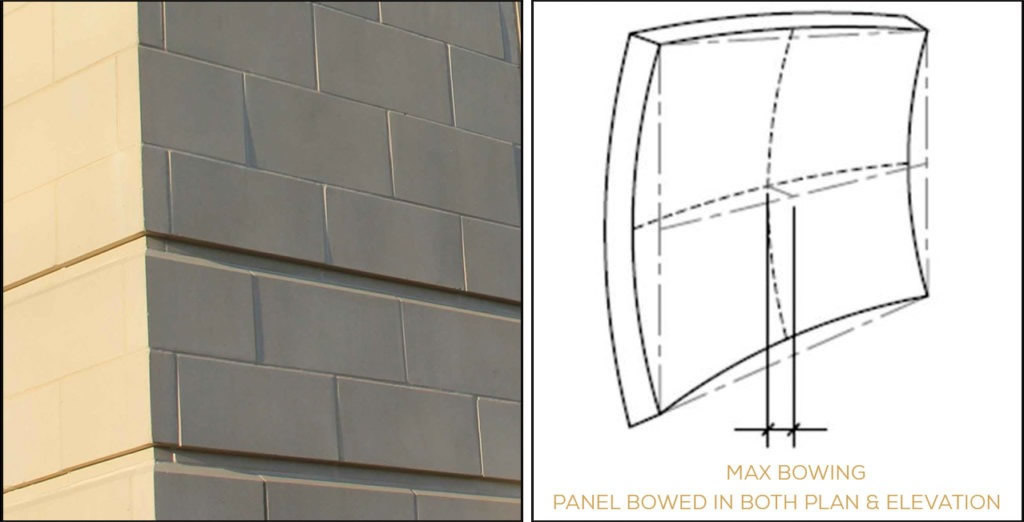

BOW AND TWIST Technical Bulletin #55

This new Technical Bulletin was to review two unique possibilities: Bowing, an overall out-of-plane condition in which two opposite edges of a component fall in the same plane and the portion of the panel between the edges is out of plane AND twisting (or warping), a condition in which the corners of the panel do not fall within the same plane resulting in overall out-of-plane curvature of surfaces. While bow and twist are aesthetic and not structural issues, the Cast Stone Institute’s Standard Specification defines strict limits for both conditions. This bulletin shows diagrams, how to measure, and the aesthetics under different lighting conditions.

WATER REPELLENT COATINGS Technical Bulletin #35

The purpose of a water repellent coating should be to minimize water intrusion through the outer surface of the cast stone or mortar, while allowing sufficient vapor transmission to let moisture out of the wall cavity, thereby improving weathering qualities. Proper application of water repellents can minimize efflorescence, mildew, staining and dirt. When a water repellent coating is desired, the Cast Stone Institute® recommends using a silane or siloxane (or blends of each).

Water repellent coatings are not a remedy for moisture penetration problems caused by poor details such as the improper use of flashing, lack of weep holes, non-ventilated wythe, failure of joint materials or the a use of hard mortar joints where sealant joints should be used.

Water repellents should be applied after all pointing repair, cleaning and inspection operations are completed. The application should be guaranteed by the water repellent manufacturer or the applicator not to discolor the cast stone.

CRAZING Technical Bulletin #32

One of the most frequently asked topics, crazing is a naturally occurring phenomenon. The appearance of small cracks on the surface, especially when filled with water or dirt, can be alarming since it is assumed that the fissures are running through the entire cross section of the concrete. All cement based products and many natural stones are susceptible to crazing. In general, crazing does not affect the structural integrity of the concrete and should not by itself be cause for rejection.

Crazing can be caused by any factor which causes surface tension in excess of interior tension including manufacturing, design and/or installation. Design professionals should ensure that the wall section details provide adequate ventilation and drainage behind cast stone and above flashing. Sealant joints should be used in accordance with CSI specifications and wherever thermal movement is likely.

EFFLORESCENCE Technical Bulletin #33

Efflorescence is a crystalline material, usually white, that forms on the surface of masonry walls and concrete products. While unsightly, it does not affect the structural integrity of the cast stone. It is generally caused by moisture related issues in the wall from a variety of sources. It is difficult to predict whether efflorescence will occur, but when it does, the sooner it is removed the better. For new building construction it is recommended that a cleaning procedure, using the appropriate cleaning agent and method, be performed to remove any debris and efflorescence.

BASIC COMPARISONS AMONG VARIOUS MASONRY MATERIALS Technical Bulletin #49

All concrete products are not equal! Cast stone standards are designed to provide a product that is expected to perform exceeding 100 years. When determining masonry products to be used as an architectural trim, feature or ornament for buildings and other structures, a relative high compressive strength, relative low absorption, freeze thaw testing as per ASTM C666 and the ability to include steel reinforcing should be considered.

Note that architectural cast stone is tested as per ASTM C1194 and ASTM C1195 which is testing of 2 inch cubes. Information and an easy to read table is included in the bulletin to assist in proper specification.

INSPECTION AND ACCEPTANCE Technical Bulletin #36

This Bulletin focuses on inspection and acceptance of cast stone at time of delivery and prior to installation. The inspector should be familiar with cast stone specification and contract documents then check the color and texture of the approved sample against the delivered product. Visibly dry cast stone should approximate the color and texture of the approved sample when viewed under typical lighting conditions and show no obvious imperfections other than minimal color and texture variations from a 20 foot distance. Minor variations in color and texture should be expected within limits of the approved range of samples. Some projects will show more color variation than others depending on the type of cement, integral color and cleaning procedures.

In addition to color and texture, the inspector and/or mason should be familiar with the dimensional requirements of the installation as they pertain to joint sizes and interfaces with other materials. The cast stone should be true in shape, free of large cracks and ragged edges and within the tolerances specified in the contract documents.

Wherever possible, an investment should be made in mockup panels and/or sample units. The sample units should demonstrate a variety of shapes and casting configurations and include vertically cast surfaces if they are specified.

JOB SITE HANDLING AND INSTALLATION Technical Bulletin #37

This Bulletin was updated significantly to give the designer, mason and others proper guidance for delivery, storage, setting, touch-up and repair, cleaning, pointing, caulking and sealing work done on site. Where the project specification may not include a particular issue, the industry standards should be followed. Information on what should be completed prior to delivery as well as when the cast stone arrives to the job site, on site storage, setting recommendations, and more.

Examples of the recommendations include: alignment of trim items with control joints; bridge parapet coping over control and expansion joints; hardscape project guidance, wetting of cast stone prior to setting, anchors must meet specified standards and be non-corrosive and cast stone slots to receive anchors should be completely filled with project approved material usually mortar, non-shrink grout or epoxy.

CLEANING Technical Bulletin #39

Transportation and storage of the cast stone is important as it impacts the amount need for cleaning after construction. Recommendations on storage are included in this technical bulletin as well as protection after installation of the cast stone during construction.

The most common stains due to construction are dirt, mortar smears and efflorescence. A general rule of thumb is to use the least aggressive cleaning material and method to clean the building. Direct high pressure power washing and sandblasting are not recommended procedures for cleaning cast stone. Metal fiber brushes, rubbing stones and any tool or device that can scar the cast stone not to be used for cleaning cast stone.

TOUCHUP AND REPAIR Technical Bulletin #38

Even with special care and protection, cast stone may still become chipped from time to time and a certain amount of touch up is to be expected. Damage to stone either while in transit or during installation is usually classified as a repair. A properly executed repair will not match in color immediately. Dry tamp produced cast stone will appear lighter where repaired, while wet cast produced cast stone may appear darker. Repairs, matching immediately or in two or three days, have a tendency to change color later on after weathering.

HOT WEATHER SETTING PRACTICES Technical Bulletin #48

Temperatures above 90° F (32° C) are considered hot weather which creates a concern about the evaporation of water from the mortar. Cast stone is one of the materials in masonry construction that is least affected by hot weather. However, the interaction between the cast stone and mortar is critical. If sufficient water is not present, the strength of the mortar and bond between the cast stone unit and mortar may be compromised. A suggest list of guidelines for masonry construction using cast stone under these conditions is included in the bulletin.

COLD WEATHER SETTING PRACTICES Technical Bulletin #41

This technical bulletin provides guidelines based on the building code and industry recommendations for the setting of cast stone in cold weather conditions. Temperatures as well as installation, touch up and repair and admixture guidelines are included.

Properly manufactured, designed and installed, cast stone can result in an architectural project of enduring beauty to be enjoyed for decades. When specifying cast stone on a project, be sure to call out for a Cast Stone Institute Producer Member and all parties need to hold to that specification. Certified Producer Members of the Cast Stone Institute are engaged in the relentless pursuit of excellence in manufacturing. This provides the owner the quality cast stone the project deserves.

Jan Boyer has been the Executive Director of the Cast Stone Institute since 2006. She currently serves on the Board of Directors for the Masonry Alliance for Codes and Standards (MACS) as Board Secretary and serves on several administrative committees for The Masonry Society. She also sits on the ASTM C27 Committee under which Architectural Cast