Nearly all masonry projects have some type of reinforcement installed in horizontal bed joints. It is used for shrinkage control, primary reinforcement, and to meet prescriptive code requirements:

- Used with movement joints, to control shrinkage in concrete masonry construction. All CMU construction should have horizontal reinforcement – this applies to CMU veneer as well as load-bearing masonry.

- To meet minimum horizontal seismic reinforcement requirements of the TMS 402 code.

- In all stack bond masonry, as required by required by the TMS 402 Code (could be either joint steel or reinforced bond beams).

- As primary structural reinforcement for walls spanning horizontally between pilasters or columns. (Figure)

- As shear reinforcement in shear walls, reducing or eliminating the need for reinforced bond beams.

- To provide bonding between wythes where the collar joint is grouted solid.

One cautionary note is to NOT use tri-rod joint reinforcement in cavity wall construction. The cross rods spanning narrow cavities don’t have enough flexibility to accommodate movement between the veneer and structural backup. Cracks and lifting can occur as a result.

Older codes had special seismic requirements for veneer anchorage, where wire rods were embedded in mortar joints and clipped to veneer anchors. Recent research showed that these rods did not improve veneer seismic performance and the requirement was removed from TMS 402.

Joint reinforcement with No. 9 gage (0.148 inch diameter) side rods and cross rods is the most common size used for shrinkage control. Engineering design sometimes calls for heavier 3/16” joint reinforcement to meet seismic or shear requirements. When used on exterior walls, code requires joint reinforcement to be hot-dipped galvanized for corrosion protection. Mill galvanized (electroplated) finishes are acceptable only at dry interior applications with low humidity.

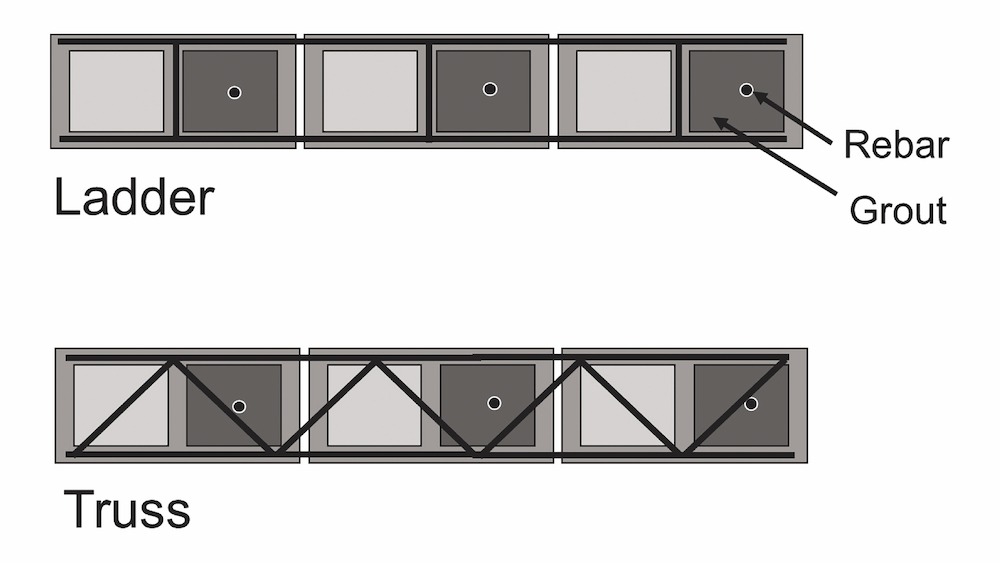

Cross rods may be straight, in ladder-type joint reinforcement, or diagonal, in truss-type joint reinforcement. Diagonals cross rods in truss-type reinforcement have a tendency to block reinforcement and grout placement. Ladder-type joint reinforcement is preferred for reinforced masonry walls: cross rods are 16” apart, spaced to lay atop cross webs, leaving CMU cells open to facilitate rebar and grout placement. (Figure)

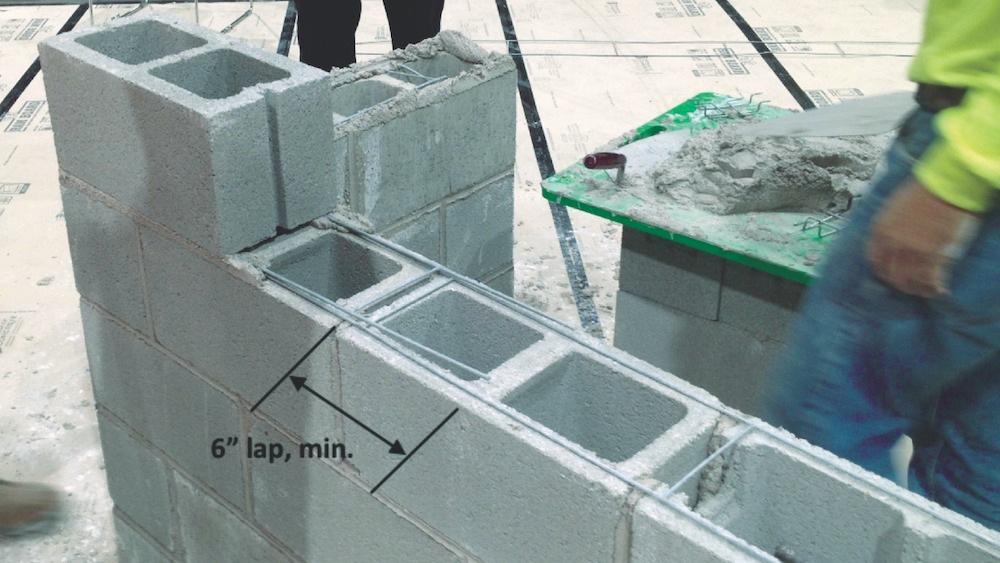

Joint reinforcement is installed by laying it atop a block course, adding mortar as the next course is laid (photo). Mortar flows around the dry-laid reinforcement to bond it to the units above and below. Joint steel is held back at least 5/8” from the wall face, per code, for proper mortar bond and to also provide added weather protection against corrosion.

Joint reinforcement must be continuous to work properly and carry stress along the length of the wall. This means field cutting and bending side rods continuous around corners or using pre-fabricated corner sections (Figure). Side rods are lapped for continuity to transfer stress from one section to the next. Laps must be at least 6” (40 bar diameters for No. 9 gage side rods) (Figure).

Check with your project engineer about how to treat joint reinforcement at control joints. Most commonly joint steel should stop short and not cross control joints, but that is a decision left to the engineer.