Many of you have responded very positively to our Question and Answer articles. Hearing from many contractors about their take on the industry seems to be beneficial to starting a larger discussion. In this Q&A, we speak to a supplier and two contractors about what to look for in a mixer. It’s important for us to give both suppliers and contractors a voice through our articles, so please let us know if you find this hybrid-style version to be more useful than the ones that only include contractors. We will make sure to get more like this in the rotation!

What are important things contractors should look for in a mixer

Contractor’s View:

Tom Cummer, Cummer Masonry: The important thing to look for in a mixer or any other equipment, would be to see how it will perform compared to other equipment on the market. Is it the same old system or are there new and better ways out there to save on labor? A lot of equipment today is designed to save labor, as it is labor that is the most expensive and the hardest to find.

Addison Kalish, Kalish Masonry, LLC: They must have a Honda motor with an excellent air filtration system. Bearings need to be easily accessible for daily maintenance and/or replacement if necessary. EZG Mixers aren’t restricted to expensive parts that can only be purchased through the manufacturer. Replacement parts can be bought at local hardware stores. Be aware of the tub thickness, some are thin, bend and/or dent and wear through quickly.

Supplier’s View:

Steve Wheeler, EZG Manufacturing: A contractor should look for quality and ergonomics for the price they are paying. Consider that only 30% of the cost of a piece of equipment is incurred the day it is purchased while 70% is incurred during everyday use. Here are some key features that contractors should look for when purchasing a new mixer.

The thickness of the drum: Many mixers are built with thin gauge steel and would be alright with limited use, but for contractors that mix daily a thin gauge drum will develop holes quicker which leads to replacing or repairing the drum.

What are the mixers capabilities? Will the mixer mix grout, concrete and mortar? A good mixer will allow the contractor the ability to mix grout, mortar and concrete when needed. This is accomplished by having the paddle rubber blades the correct distance away from the drum to allow the material to flex the rubber without damaging the paddles or the drum.

The height the operator is required to load the mixer: EZG Manufacturing builds the Mud Hog mixers so they load at the operator’s waist instead of the chest like most mixers are designed to load. With the low load and high dump feature that is standard on the Mud hog mixers, the cylinders on the mixer lifts the weight instead of the operator straining his or her back.

What innovations have you seen in mixers?

Contractor’s View:

Tom Cummer: There are different innovations out in mixers. Some are the sizes of them. Some are the way they operate. Some mixers are even designed to mix and take right to where the material is needed and dispense it exactly into place so there is less labor and down time.

Addison Kalish: The biggest would be the hydraulic dumps and the reverse paddle option. The reverse paddle option allows for quicker cycle times at the mixing station. It also eliminates the possibility of jamming the mixer due to volume/water ratio. With the reverse feature, you can now “save” the batch, which in turn, saves time. Time is money!

Supplier’s View:

Steve Wheeler: Operators will sometimes forget to add the right amount of water into the mix plugging the mixer during operation. Without the reverse option, if a mixer plugs, it has to be shut down and dug out while others are standing and waiting on mixer to be cleaned. This causes delays and lost time. The mixer must be hydraulic driven in order for it to reverse the paddles to easily unplug to allow the batch of mortar or grout to finish mixing.

Mixers that have electric start engines. Electric start engines allow the operator to turn a key to start the mixer instead of using the pull cord. Pull cords can break at any time leaving the operator scrambling to find a new cord while the mixing process come to a halt.

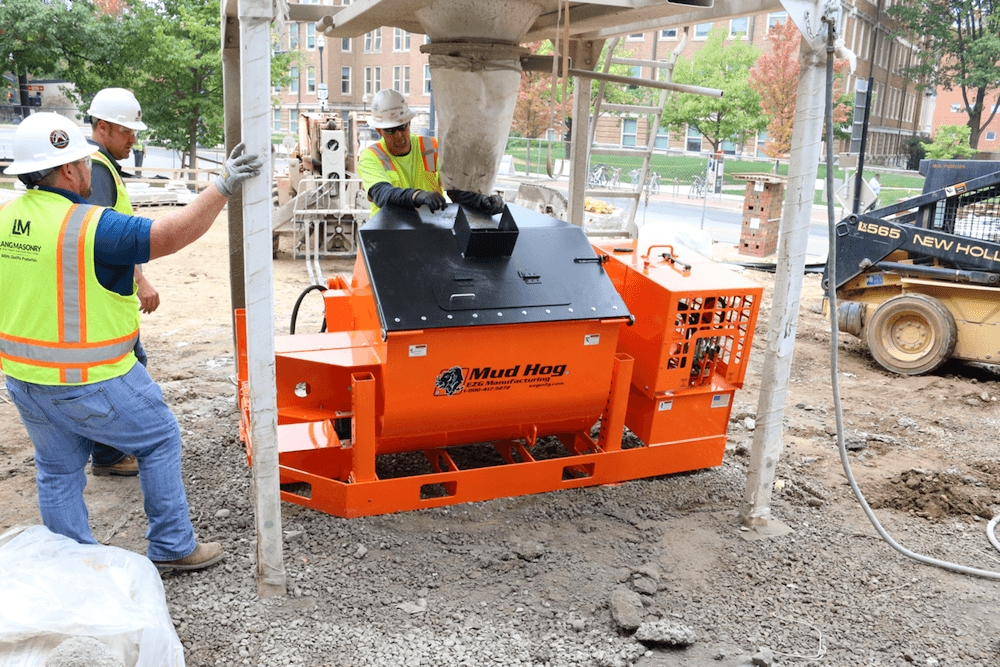

Solid dust covers: Mixers that have the option to add a solid dust cover has become critical. Solid dust covers that are built correctly could reduce up to 80% of the dust a mixer produces. EZG Manufacturing offers solid covers for use with the silo tower systems as well as solid covers for field mixing. These solid covers can also be added to any of the existing Mud Hog or EZG mixers.

What common mistakes do you see when contractors are buying and using mixers?

Contractor’s View:

Tom Cummer: The most common mistake is to continue to use the same old equipment that we have always used because we are afraid of change. A lot of people are stuck in the ways of doing things and cannot go outside of their comfort zone. When they are able to do this they end up creating ways of doing things a lot easier with less labor. Thus saving time and money.

Addison Kalish: We (Kalish Masonry) make sure that all of our employees are properly trained in using our mixers and enforce a very strict, zero tolerance policy in regards to safety. The most common mistakes I see many people doing is removing the grate or the cage at the motor. This is just asking for injuries and/or an OSHA violation. Use the equipment properly.

Supplier’s View:

Steve Wheeler: If a contractor would take a few minutes to list what they need and want out of a mixer then the style and type of mixer becomes clear. This exercise will help the contractor avoid making a quick decision that could cost them more money in the future. Once a mixer is purchased if the operators follow the maintenance procedures recommended by the manufacture this will help ensure the mixer is performing day in and out while saving on potential costly repairs.

What advice would you give to someone looking for a mixer?

Contractor’s View:

Tom Cummer: Research all methods of doing things before buying any equipment. Purchase the right equipment now and use it to get profit. Too many companies are trying to make money with the wrong equipment and trying to save up to buy the right equipment. They need to buy the right equipment and the profits will come. The wrong equipment is not making any money and they will never be able to get ahead. Everything boils down to how we can save on labor. Everyone is trying to make and save money with the wrong equipment to purchase the right equipment. I say buy the right equipment and the profits will come.

Addison Kalish: I have been working in the Masonry industry for 25 years and about 5-6 years ago, my company has switched over to using all EZG Mixers. From our small 7 cubic ft. residential style to our 20 cubic ft. hydraulic dump, EZG Mixers are by far the best, heavy duty constructed and most reliable mixers on the market today.

Their customer service is a huge factor in this as well. I had an issue with one of their mixers a few years ago and brought it to their attention. Not only did they acknowledge my concerns, they ended up changing their design so that it worked better. This is a company that truly cares about their customers.

We used to use all “stone” brand mixers but after they were bought out, the quality and cheap construction was evident within a short amount of time. We’ve tried a few other brands in the past but none of them last long and are sitting in our shop collecting dust. Do your research. EZG isn’t the cheapest but they are definitely worth the extra money.

Supplier’s View:

Steve Wheeler: When a contractor is looking for a mixer, take the time to research the different styles that are available. See what each mixer offers and choose the one that best suits what your crews need on a daily basis. The correct choice in a mixer will not only save you money on each job but also will save you money and time by not constantly breaking down requiring costly repairs and losing efficiency.