MASONRY MADNESS® is one of the highlights during the World of Concrete. This top-ranked attraction is a hit at the annual trade show, and the 2018 version did not disappoint. This year, the respective exhibitions and competition areas moved to the Bronze Lot.

Here, Tent City and The Masonry Innovations and Workforce Development Zone provided the opportunity for attendees to see all the latest and greatest from the industry. From Tuesday January 23rd through Thursday January 25th, attendees could take part in live, hands-on learning demonstrations that showcased the most recent innovations impacting the masonry industry.

From cutting-edge products and equipment to technology-driven software systems and innovative masonry wall systems, experts in their field provided information and training that will change how masonry projects are built in the immediate future.

MASONRY Magazine took some time to shoot quick videos with many of the exhibitors in the Bronze Lot, and here is a selection of some of what they talked about. For the full videos, please visit our website and watch the demos for yourself!

iQ Power Tools iQMS362™ Dust Control Masonry Saw

Paul Guth, Product Development Manager at iQ, took some time to show us the brand new iQMS362™. The masonry saw features a 16.5-inch blade, a 5 ¾-inch depth of cut, and a 24-inch length of cut. Featuring integrated vacuum, filter, and dust containment systems, which allows for easy cleanup at the end of the day from a tray in the bottom of the unit.

We got to see the unit in action while in the Bronze Lot, and the lack of water and dust seems like this could be a game-changer for contractors looking for a way to stay compliant with OSHA’s Final Ruling on Crystalline Silica Exposure. Additionally, the unit didn’t heat up and stayed cool because of the vacuum system’s airstream.

Additionally, what makes the unit so unique is the portability. It features an integrated stand with gas-assist shocks, which makes the saw very easy and portable to store and move.

Hohmann & Barnard TBS-Thermal Brick System

Jeremy Douglas, Director of Architectural Sales at Hohmann & Barnard, Inc., spoke with us about some innovations coming from the company. During our time with him, he showed off the company’s thermal brick support system. With a growing interest in offset relieving angles, Hohmann & Barnard sought out to make them more contractor friendly.

Featuring minimal attachment points back to the main structure, the system allows for the installation of continuous installation behind. Now, the systems can be designed with up to four and five inches of insulation behind it, allowing for more continuity. For contractors, this allows for a much better air barrier detail, limiting it only to the penetrations to the air barrier.

Featuring minimal attachment points back to the main structure, the system allows for the installation of continuous installation behind. Now, the systems can be designed with up to four and five inches of insulation behind it, allowing for more continuity. For contractors, this allows for a much better air barrier detail, limiting it only to the penetrations to the air barrier.

Construction Robotics SAM and MULE

Construction Robotics showed off their SAM100 Semi-Automated Mason, a bricklaying robot designed for onsite masonry construction. Though the robot has made appearances at the show in the past, Construction Robotics had an impressive new display in the Bronze Lot.

Debuting at the show was the company’s new MULE, which differs from SAM in that it’s aimed at relieving some of the load for block laying masons. By assisting the installer through doing a lot of the heavy lifting, it eases fatigue and physical stress placed on older, more experienced block layers.

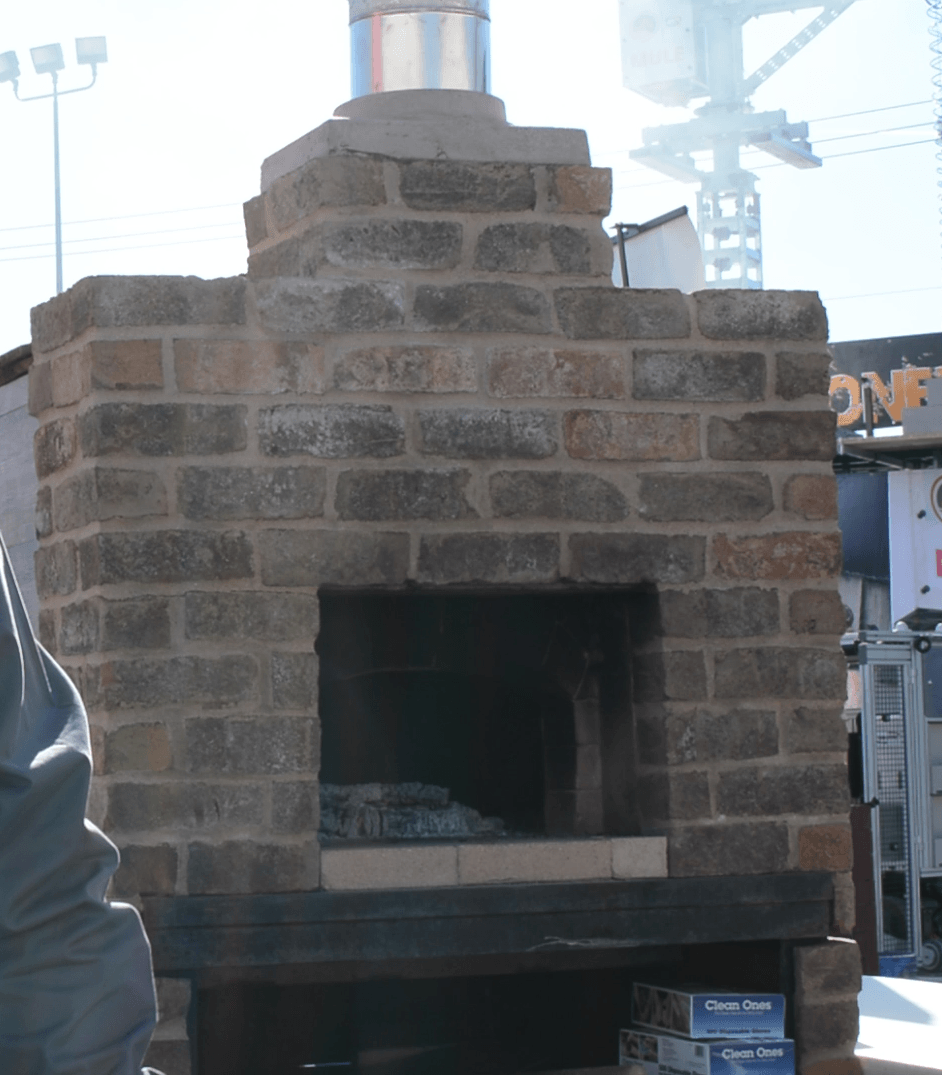

Masonry Heater Association

Chris Prior, the President of the Masonry Heater Association told us a little bit about the organization. The MHA is an association of builders, manufacturers, and retailers of masonry heaters and wood fire bake ovens. With a desire to promote the industry, sponsor research, development and testing, and work to shape regulations, codes and standards. Additionally, they want to inform and educate the public about what they do.

In their booth, the MHA featured several examples of the work their members do. All day, they were cooking pizza in their wood-fired bake oven and talking to the hordes of attendees in the Bronze Lot about what they have to offer.

Additionally, they showed off a masonry stove; a heat-storage type of wood-burning appliance. Essentially, there is a wood box that holds approximately 50 lbs. The fire burns rapidly over a 4-hour period. The labyrinth of flue channels running through it — sometimes the flame path can be up to 20 feet before hitting the flue exit — and as the fire, smoke, and heat travel through it. Once hot after a 4-hour burn, it can heat a whole house for up to 24 hours.

All this from basic technology and processes from about 250-300 years ago.

NSVI King Cutter™ Stone Trim Tool

Brett King, Midwest Sales Representative at Natural Stone Veneers International, took some time to show off the company’s King Cutter™ Stone Trim Tool. The company spent most of their time in the Bronze Lot demonstrating various ways to lay stone with different types of mortar, but was also showing off the new tool.

Designed to bypass the need for a saw, the King Cutter allows masons to score the top of a piece of stone and trim it to the size they need. The benefits of the King Cutter™ are the natural edge that remains, no need for power, nearly no dust in the process, and lightweight design.

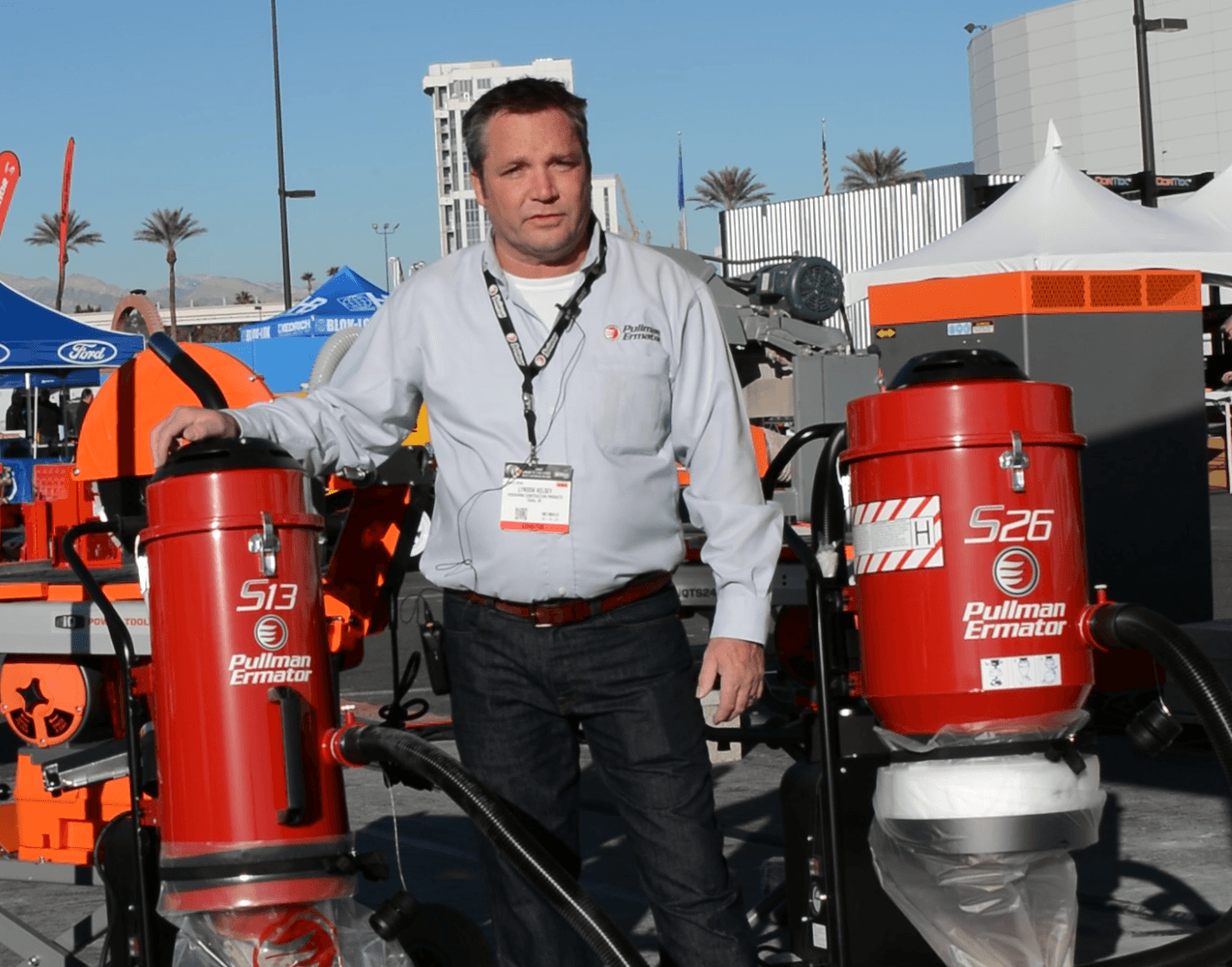

Pullman Ermator S13 Single-Phase HEPA Dust Extractor and S26 HEPA Dust Extractor

Lyndon Kelsey, North American Sales Manager for Ermator USA, took a few moments to tell us about the company. Originally out of Sweden, the company has been selling their products in the US for about 12 years.

Showing off two of Ermator’s most popular models, the S13 and the S26, Lyndon went into detail about each. Both units are designed to pass the new OSHA regulations on dust control.

The S13, according to Lyndon, is 130 CFM with 100 inches of water lift and is designed for the masonry industry’s hand tools. The S26, on the other hand, features 258 CFM with 100 inches of water lift. The unit is designed to keep up with two 7-inch grinders with the available twin hose kit.

SPEC MIX® D2W Workhorse

Brian Carney detailed some of SPEC MIX’s newest innovations that are designed to ensure contractors are working safely, efficiently, and productively. During our chat, Brian detailed the new SPEC MIX D2W Workhorse. This Continuous Mixing System, designed for 80lb or smaller bags, is the first to hit the market that runs off of 120-volt power.

This power allows for mason contractors to work on a jobsite with a portable mixing system. To use the unit: hook up a pressurized water source, dial in the water ratio, once it’s going flip the switch and begin to feed bags. The machine output is up to three cubic yards of mortar — including coarse grout — in an hour.

When going from floor to floor or doing interior work, contractors can choose to make one bag or three pallets of mortar. The workhorse is ready to do it, and SPEC MIX debuted a modified cart system for the unit, which allowed for easy transport.