Air Barriers and Insullation

Improving Building Insulation

Any time mason contractors gather, whether at a meeting, networking event or trade show, air and moisture control are main topics of discussion. Barriers and insulation are fast becoming more prevalent in the mind of the mason contractor as he creates project schedules. We wanted to learn more, particularly about building insulation. So Masonry consulted Dr. Maria Spinu, Ph.d., LEED AP, for some answers. Dr. Spinu is the building science and sustainability leader for DuPont Building Innovations. Following is what she had to say.

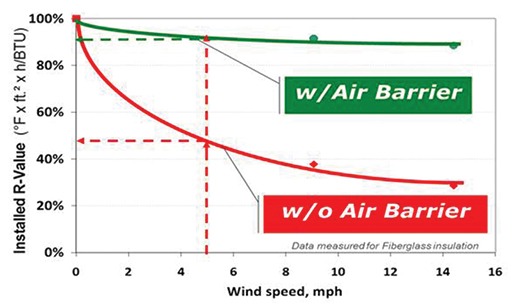

Dr. Spinu: One effective way of improving insulation performance is protecting it against airflow (wind-washing, the air movement driven by wind pressures), which can significantly reduce the rated R-value of the insulation. Not all insulation types are equally affected by airflow. Fibrous type insulation (e.g. fiberglass batt insulation) can lose up to 50 percent to 60 percent of its rated R-value at wind speeds of up to five mph (see Graph 1). A continuous air barrier will prevent airflow and loss of effective R-value. Air barriers also protect against direct air leakage, which could transport significant amounts of heat and could account for up to 40 percent of the heating energy loss.

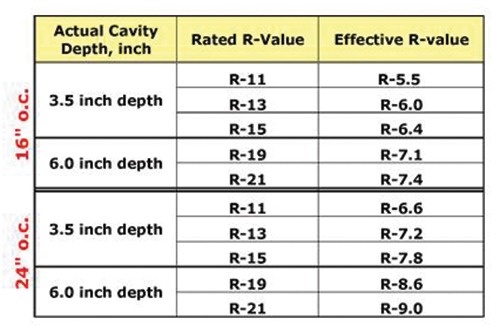

Another way of improving thermal insulation performance is by reducing thermal bridges. Thermal bridges are regions of relatively high thermal conductance in a building assembly (e.g. steel studs). The chart in Table 1 shows a few examples of the impact of thermal bridging on the effective R-Value of cavity insulation in steel-framed walls, and the significant improvement in effective R-value with the use of continuous insulation.

Another way of improving thermal insulation performance is by reducing thermal bridges. Thermal bridges are regions of relatively high thermal conductance in a building assembly (e.g. steel studs). The chart in Table 1 shows a few examples of the impact of thermal bridging on the effective R-Value of cavity insulation in steel-framed walls, and the significant improvement in effective R-value with the use of continuous insulation.

Continuous Insulation (c.i.) is the insulation installed outside the structural members of a wall assembly, without thermal bridges other than fasteners and service openings. The 2012 IECC energy codes require continuous insulation in steel framed wall assemblies. Wood studs have lower thermal conductivity, so the impact of thermal bridging in wood-framed wall assemblies is not as high.

Dr. Spinu: Materials with high resistance to heat flow are known as thermal insulation materials and are used to control heat loss through conduction. The most common ways to compare the insulating value of a material or assembly are R-value and U-value.

The R-value is a measure of the resistance to heat flow through a material, under specified conditions. The higher the resistance to heat flow, the higher the R-value, the better the insulating value of a material. There are many ways to express the R-value, but the most common is the Rated R-value which is the thermal resistance of the insulation as specified by the manufacturer and expressed in units of [h??ft2????F/Btu]. This is, most often, quite different from the actual installed value, which will depend on installation quality as well as other assembly components.

Graph 1: Wind Washing Effect on Thermal Insulation Performance

Source: Impact of Airflow on the Thermal Performance of Various Residential Wall Systems utilizing a calibrated hot box, Thermal Envelopes VI/ Heat Transfer in Walls – Principles

The U-value [Btu/h??ft2????F] is the inverse of R-value and is a measure of the rate of heat flow through a material. The lower the rate of heat flow, the lower the U-value, the better the insulating value of a material or assembly. The U-value is generally calculated for common assemblies and are available in ASHRAE 90.1 and other energy codes.

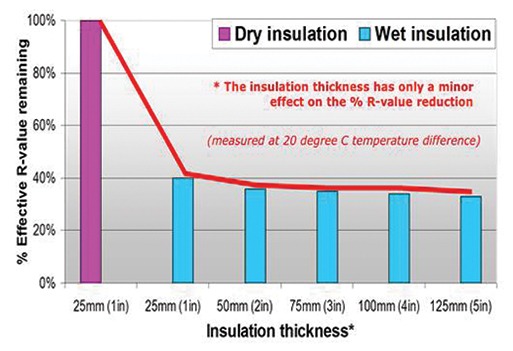

Dr. Spinu: As previously described, a continuous air barrier such as DuPont Tyvek air barrier systems can protect thermal insulation from wind-washing, which can significantly reduce its rated R-value. Another way DuPont Tyvek water resistive barrier systems (WRBs) can contribute to thermal insulation performance is by protecting the insulation from getting wet. Wet insulation is much less effective than dry insulation, as exemplified in Graph 2, which shows the percentage of remaining R-value for wet insulation of different thicknesses, when compared with the rated R-value of the dry insulation.

The data show that wet insulation can lose up to 60 percent of its rated R-value, and that the percentage loss is only slightly dependent on the insulation thickness. The problem is not with the insulation itself, but, rather, the moisture in the cavity, which can short circuit the insulation through vapor transport mechanism (excess moisture can diffuse from one side of the envelope to another, as the temperature changes, e.g. between day and night).

Table 1: Examples of impact of Thermal Bridging on effective R-Value for Steel-framed Walls

Source: ASHRAE 90.1, TABLE A3.3 Assembly U-Factors for Steel-Frame Walls

Dr. Spinu: In addition to the factors already mentioned above, poor thermal insulation performance is mostly due to poor installation practices, not necessarily bad products.

A few examples include:

- Lack of continuity for the air barrier, which could lead to air leakage and could affect the thermal insulation performance as discussed previously

- Lack of continuity and improper shingling of WRB, which could lead to water penetration and loss of thermal insulation performance as described previously

- Discontinuity of thermal insulation or compressing of thermal insulation, leading to non-uniform R-value across an assembly

- Poor installation of field applied insulation such a Spray Polyurethane Foams

- Excessive thermal bridging (e.g. balconies, awnings, or other architectural features that could introduce significant thermal bridging and short circuit the thermal insulation).

Dr. Spinu: One major development in addressing building envelope thermal performance is the energy code requirement for continuous insulation described above. However, the type of thermal insulation and the way the insulation is added to the wall assemblies could have unintended consequences on moisture management, not always understood by the practitioners. This challenge is starting to be acknowledged by the building science community, but solutions are not always properly implemented.

Graph 2: Moisture Impact on Thermal Insulation Performance

Source: Controlling the Transfer of Heat, Air & Moisture through the Building Envelope M.C. Swinton, W.C. Brown, G.A. Chown

Dr. Spinu: One recent trend is the building envelope commissioning, which could identify and correct potential installation mistakes before the building is covered with exterior cladding. Even though this is not yet a mandated practice, building envelope commissioning is being promoted by trade organizations such as Air Barrier Association of America, and has been instrumental in effectively implementing whole building airtightness requirements by programs such as US Army Corps of Engineers.

Dr. Spinu: Effective thermal insulation and air leakage control are the two most effective measures for reducing the building envelope loads. This has significant implications on the sizing of the heating and cooling equipment and the energy use for heating and cooling, the largest share of energy use by buildings.

Dr. Maria Spinu, Ph.d., LEED AP

Dr. Maria Spinu, Ph.d., LEED AP