Hardscaping Case Study

A Retaining Wall for Garden Gulch

Near the town of Parachute in the mountains of Colorado, Bryan Miller of Miller Walls found himself in the middle of a massive field of slate and rubble, unable to continue up slope and with absolutely no chance of retreat.

Miller had spent three days at the site, trying to determine how – or even if – the retaining wall designed for the Garden Gulch access road could be built. What he didn’t expect was a total time of four hours to traverse three-quarters of a mile, just to escape what he thought was a project walk through.

Garden Gulch is an eight-mile access road to natural gas drilling operations and production facilities on the Logan Mesa. Built in 2006, it reduced truck travel from one hour, 45 minutes, to a 30-minute haul. It was constructed using conventional cut-and-fill techniques and by removal of a number of cliff sections.

This created a huge scree slope of rubble and boulders above the roadway. The unstable slope not only posed a safety hazard to the roadway, but also potentially could impact area waterways. With up to 1,000 trucks moving through per day, closing Garden Gulch was not an option. So, a “mechanically stabilized earth” wall was the obvious choice.

In 2011, a consortium of engineers designed a terraced, segmental retaining wall (SRW) parapet wall, using Diamond Pro Stone Cut wall units supplied by Pavestone LLC. This consortium included Sean Chang, P.E., of Ground Engineering Consultants; Don Armstrong, senior engineer of Anchor Wall Systems; and Lance Carter of Strata Systems.

As the portion of the parapet wall next to the slope was designed to catch any slide material, it was manufactured in a grey concrete, while the front exposed section was manufactured in a custom two-color blend. Despite of the vast experience of the engineering team, the project constraints were such that multiple re-designs were required, many of which were creative in both concept and design. In concert with Miller Wall, solutions included reducing the amount of backfill compaction, as the large compaction equipment would have further destabilized the slope, increasing dangers to the construction crew and making construction a near impossibility.

To date, building the Garden Gulch retaining wall has been considered the toughest installation experience for Miller Wall. Extra crew members were hired to stand watch and provide warning of falling rock. As the mountainside was excavated, the slope became steeper and further destabilized, requiring constant adjustment of machines and crews. An onsite seismic device would register movement of the upper slope and sound a warning siren if the slope moved more than half an inch. When the siren wailed, all work ceased, and everyone quickly moved to designated safe areas.

Due to the location, construction could not begin until after the winter snow melted, but had to be completed prior to the summer monsoons typical for the Colorado Rockies. The site also is remote, necessitating careful planning for daily transportation of workers. To address the accelerated construction requirements, multiple crews worked 12- to 14-hour days for 54 days straight.

When installation outpaced supply, Pavestone LLC was contacted, occasionally requiring Sunday deliveries to fill the void. Despite this, the only delays were due to two rock slides, which shut down the project while the debris was removed from the roadway.

Bryan Miller notes that, had he known then what he knows now, he probably wouldn’t have done this job. “It was one of the most nerve-wracking, high-stress projects we’ve ever been involved with,” says Miller, “but also one of those jobs you can feel proud of having completed.”

| Product Watch |

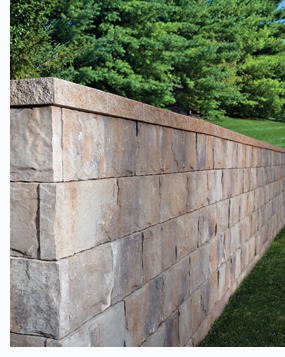

Belgard Hardscapes has introduced the Mega-Tandem Mass Retaining Wall (MRW) block, a wall block system with the natural look of stone. The system’s size and mechanical structure allow for building reinforced walls up to 15 feet high and gravity walls up to 10 feet without reinforcing. “The size and connectors in the Mega-Tandem MRW system allow for a gravity wall height of up to 10 feet without a surcharge,which is ideal for wall projects where it is difficult to impossible to excavate for stabilization for a retaining walls,” says Al Pfannenstein, national retaining wall manager for Belgard Hardscapes. “This height is a sharp contrast to the traditional three-foot height that SRW products typically can achieve without reinforcement. The structural benefits combined with Mega-Tandem’s look make it an unmatched innovation in the wall block marketplace.” Mega-Tandem features a patent-pending, positive mechanical connection. The reinforced polypropylene connecting members create structural integrity in curved or straight retaining and freestanding walls. Available in a 12 X 24 panel weighing 65 pounds, the system has a running bond configuration, so no patterns are required. Meeting ASTM standards C-1372 and C-1262, Mega-Tandem’s 8,500 psi compressive strength concrete makes it suitable across the country, even the coldest environments, where it can withstand harsh freeze-thaw cycles.

Mega-Tandem also offers national appeal, because of design diversity that appeals to varying regional color trends. Available in three color blends, Mega-Tandem comes in 12 different facial textures with the classic look of natural chiseled stone. “The design versatility offered by Mega-Tandem provides flexibility for better integration of retaining walls in building and landscape designs of commercial properties and homeowners’ outdoor living spaces,” Pfannenstein says. For more information and a how-to video, visit http://youtu.be/WD5fxpFVMnI. |