>>> Case Study:??Green Building

Blended Cements Aid in Sustainable Design, Construction

In pursuit of LEED ratings and other green building goals, healthcare organizations are increasingly relying on innovative cement blends in the construction of new high-performance facilities.

Shown is the Gundersen Lutheran Health System campus.

Image courtesy of Ellerbe (AEComm)

As the demand for environmentally friendly design and building practices continues to grow, innovative cement blends from Lafarge North America are making a strong contribution to the construction of high-performance healthcare facilities around the country. Gundersen Lutheran Health System in Wisconsin, the Mayo Clinic in Minnesota, and The Moses H. Memorial Hospital in North Carolina are just three examples of healthcare construction projects using blended cements to achieve high-strength, long-term durability and resource conservation.

Cementitious blends, which are a combination of Portland cement and one or more supplementary cementing materials (SCMs), have many properties that contribute to sustainable building goals, such as those prescribed in the LEED green building rating system. Their use not only results in durable, high-performance concrete, but also it saves virgin raw materials, lowers energy consumption, and turns by-products from other industries into resources that would, otherwise, be disposed of in landfills. The most common SCMs are slag cement (a by-product of the iron-manufacturing process), fly ash (a coal combustion by-product from power plants), and silica fume (a by-product of manufacturing silicon metals and ferro-silicon alloys).

When Gundersen Lutheran Health System’s multi-year campus renewal project is complete, the new facility in La Crosse, Wis., will achieve high marks in sustainability. Designed following LEED principles, the center’s new hospital will feature numerous environmentally friendly elements in areas such as energy efficiency, recycled construction materials and building design.

In addition, many of the project’s construction materials are being produced locally, including the concrete containing Lafarge’s Type I/II Portland cement and Columbia Class C fly ash. A parking ramp at the medical center also used Lafarge’s SF cement, which is produced by blending Portland cement and silica fume. The project’s first phase of construction is scheduled to be completed in late-2013.

About 75 miles from La Crosse, the Mayo Clinic is improving both human and environmental sustainability with the construction of a new proton therapy facility in downtown Rochester, Minn. The $188 million facility will expand the Mayo Clinic’s capabilities in radiation treatment to include state-of-the-art proton beam therapy that preciously targets tumors, maximizing the ability to cure more cancers and help people live longer. The specialized treatment facility’s eco-friendly design includes concrete containing a blend of Lafarge’s Type I/II Portland cement, Columbia Class C fly ash, and Newcem slag cement. The first treatment rooms will be available for patients in 2015.

Lafarge blended cement also is playing a key role in the construction of a $200 million, six-story North Tower at The Moses H. Cone Memorial Hospital in Greensboro, N.C. The 260,000-square-foot expansion – the largest construction project in the hospital’s 58-year history – specifies 40 percent cementitious replacement to earn LEED credits.

The LEED Gold project is using Lafarge Portland cement and Lafarge NewCem, a finely ground, granulated blast furnace slag cement engineered to achieve greater strength potential and long-term durability. By combining these cements successfully, the hospital will reduce the building’s carbon footprint. The North Tower is expected to be completed in June 2013.

| Product Watch |

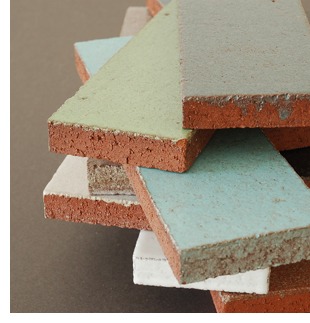

San Jose, Calif.-based Fireclay Tile has released an artistic brick collection: Glazed Thin Brick. Featuring rich organic textures, local recycled materials and American craftsmanship, Fireclay’s Glazed Thin Brick uses up to 100 percent local, recycled content and is finished with a selection of nine VOC-free natural glazes. Fireclay’s Glazed Thin Brick gives endless options for any commercial and select residential designs. San Jose, Calif.-based Fireclay Tile has released an artistic brick collection: Glazed Thin Brick. Featuring rich organic textures, local recycled materials and American craftsmanship, Fireclay’s Glazed Thin Brick uses up to 100 percent local, recycled content and is finished with a selection of nine VOC-free natural glazes. Fireclay’s Glazed Thin Brick gives endless options for any commercial and select residential designs.

Fireclay is sourcing its thin brick from a local supplier, McNear Brick and Block, located only 65 miles from Fireclay’s sustainable manufacturing facility. McNear is the oldest California brickmaker and one of only three still in existence in California. Even more exciting is that McNear is the only brickmaker in the United States that incorporates recycled materials, consisting of reclaimed, landfill-bound recycled clay and shale from local excavation sites into its brick. For more information, visit www.fireclaytile.com. |