Saw Blades

Strides in Saw Blades

Long life, durability and a reasonable price – these are what you need in a masonry saw blade, and manufacturers are answering the call. An abundance of research and development are going into the technology behind masonry saw blades. For you, the end-user, this means more hours on the life of the blade, near indestructibility, and a price tag that doesn’t blow your skirt over your head.

In the throes of the green movement, environmental responsibility for manufacturers of any and all equipment is at an all-time high. And saw blade manufacturers have met this demand. Husqvarna, for instance, acknowledges its responsibility in environmental issues, touting a holistic approach that affects its entire operation.

“From production methods, packaging, noise and consumption of materials to the energy consumption, exhaust emissions and finally the recyclability of the products, we always prefer to use environmentally compatible materials in our production,” says Husqvarna. “We are continually replacing old materials with new, even more environmentally compatible alternatives, as these are developed.”

We can’t rightly talk saw blades without mentioning safety. Following is a list of safety tips to practice when you use diamond blades on masonry saws, courtesy of Norton Pro Diamond Products, www.nortonprodiamond.com.

- Keep the area around the saw free from debris, which could cause falls.

- Prohibit the use of the saw by unauthorized or untrained personnel.

- Keep the conveyor cart free of grit and debris, which could allow the material to slip or twist during cutting operations.

- Hold the material firmly against the backstop of the conveyor cart or guide-a-cut, keeping fingers out of the path of the blade.

- Position the saw on a firm, flat area, and be sure that the saw will not move in use.

- Replace blade collars if they become worn to less than four inches in diameter for 18- and 20-inch blades, or less than 3.5 inches in diameter on 14-inch blades.

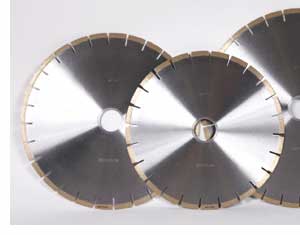

Following is a review of several saw blades available to mason contractors.

Segmented-Style Diamond Blades for Contractor Series

Affinity Tool Works

Affinity Tool Works

Troy, Mich.

Dtec, a product division of Affinity Tool Works, has added a new line of diamond blades to its Contractor Series. By pairing a segmented design with durable construction, the Contractor Segmented blades offer the speed and performance of high-quality, expensive diamond blades, yet provide an economically priced option. The new blades are able to cut a variety of building materials such as brick block, concrete and stone.

Consisting of multiple, strategically-placed 10-millimeter-high segmented sections, the Contractor Segmented blades offer a distinct longevity advantage over typical blades that only incorporate a segment height of seven millimeters. The increased segment height exposes more cutting surface, which extends blade life. Not only does this save on replacement blade costs, it also reduces costly downtime due to frequent blade change-out. The blade segments provide a break or “relief” in the blade’s rim, preventing heat transfer and allowing the blade to run cooler in both wet and dry applications.

Sandwich Tuckpointing Diamond Blades

Bosch

Bosch

Mount Prospect, Ill.

By combining tall segments and a superior diamond/metal mix with an ultra-efficient and fast sandwich-blade design, Bosch has created long-lasting tuckpointing blades that are designed to grind more surface area than competitive blades. The addition of 4.5- and five-inch in diameter sandwich blades gives the company a broad offering for use in hand-held grinders.

These eight-segment blades are made exclusively for dry tuckpointing applications. Blade widths are 6.35 mm (one-quarter inch) with cutting depths ranging from three-quarters-inch for 4.5-inch blades, to 1.25-inch for five-inch blades. Typical applications for tuckpointing blades include mortar removal in brick buildings and grout removal in commercial tile applications that include waste water treatment plants and subway tunnels. Bosch combines copper, iron, nickel and cobalt hard-bond metal powders with high-grade diamonds to create hardened 10-mm segments. These blades have high-diamond content to cut mortar efficiently and ample keyhole gullets to remove discarded cement and other debris.

Diamond Products Concrete Blades from Braxton-Bragg

Braxton-Bragg

Braxton-Bragg

Knoxville, Tenn.

Braxton-Bragg now offers a line of concrete tools and tooling from Diamond Products. Because of customer demand, the Knoxville-based company recently began carrying concrete blades, cup grinders, drill bits, and saws and drill motors. Braxton-Bragg President Rich Hassert says Diamond Products was chosen because they are the largest and highest quality tooling company that serves the U.S. market. “Most of their products are made in the United States,” he says.

One of the largest manufacturers of diamond tools in the United States, Diamond Products is based in Elyria, Ohio. Since its founding in the mid-1940s, it has grown to employ more than 300 people and markets its products throughout the United States, Canada, Mexico, Europe and Asia. In addition to stock items, the company will build customized tools for individual customers. Hassert says Diamond Products stands behind its products. “We feel that, technically, their tools are the most sophisticated of this type, and we’re very proud to be able to offer them,” he says.

Super and Universal Premium Diamond Blades

Hilti

Hilti

TULSA, Okla.

The new Hilti Super Premium (SP) and Universal Premium (UP) Diamond Blades take performance to the next level for all kinds of cutting applications in a variety of base materials. The Super Premium Blades feature Equidist technology. With Equidist, all diamonds in each segment are spaced accurately at regular intervals. This not only ensures consistent high cutting performance over the entire life of the blade, but also makes the blade more suitable for universal use.

SP Diamond Blades deliver exceptional performance in concrete, concrete block, brick and natural stone. They also provide up to 50 percent faster cutting speeds and up to 50 percent longer life than comparative super premium blades. The Universal Premium Blades are top value standard blades for cutting a variety of base materials such as concrete, masonry and asphalt. UP Blades provide maximum versatility, while delivering a high balance of speed and life.

QX Quiet Extreme Blades

iQ Power Tools

iQ Power Tools

Moreno Valley, Calif.

iQ Power Tools has created some of the fastest cutting, longest lasting, and quietest diamond masonry blades for the masonry market. The blades are available in two sizes, 14 and 20 inches. The QX Quiet Extreme Blades reduce noise from 120+ dba to 104 dba, which is an amazing 50 percent reduction in noise. The Intelligent Core Technology uses a three-part design, with a copper core sandwiched between the two strong steel surfaces. The Intelligent Core Technology dampens the piercing, high-pitch noise that can be so fatiguing and potentially damaging to an operator’s health.

Omnivore Cuts Raw Metal and Steel

World Diamond Source Inc.

World Diamond Source Inc.

Pompano Beach, Fla.

The Omnivore from World Diamond Source is the first diamond blade that cuts raw metal and steel.??In Fact, it’s the only diamond blade that cuts such a wide variety of materials, including steel, concrete, plastic, cast iron, HDPE and C900, ductile iron, rebar, PVC, angle iron, copper pipe, corrugated roofing, dry wall, wood, and stucco. The blade is four-times faster than a conventional abrasive blade.??The Omnivore also is cost effective, and it outlasts 30-50 abrasive wheels to1, and eliminates the associated down time and labor cost of changing each blade.??Call Matt Shrater with World Diamond Source for more information at 800-611-8278.