Saw Blades

Diamond Blade Education

Remember the old game, in which you start with a statement and pass it along through several people at a whisper and, at the end, find that the statement changed? In some cases, the statement changed so drastically that you wondered how it got so lost in translation. How we educate the younger generation in the masonry business about diamond blades is similar, but we hope the message stays accurate. Being consistent with our procedures and products are some of the most important pieces of information we can pass along to apprentices. This assures the perfection of the craft stays in tact.

As a representative of Norton, a large diamond blade manufacturer, I can tell you that nothing is harder to hear from a contractor than, “a diamond blade is a diamond blade.”

Who knows how this started, but it is furthest from the truth. The general application of diamond blades to masonry materials remains constant, in spite of the many changes to materials, equipment and operators. But the design and technical make-up of blades have evolved significantly.

There are five significant but simple questions:

- How deep is the cut?

- What are you cutting?

- Is the application wet or dry?

- How much horsepower for the saw is needed?

- How big is the job?

These questions are the most important to address when teaching the next generation about diamond blades. Also, remember the rule of using soft bonded blades in hard material, and hard bonded blades in soft, will allow a contractor to define what type of blade is needed for an application. At Norton, our sales people are consistent with these messages, whether it’s a full classroom with hands-on training or a simple lunch-and-learn. It is a foundation in Diamond Blades 101, and something we should all remember.

To keep it simple, we tier by good, better and best. Good, low-cost economy blades, like our Norton Classic line, have a place for quick, easy jobs in which life, production and precision are of no concern. These types of blades may be less expensive, but using them for every application can end up costing a contractor more in the long run.

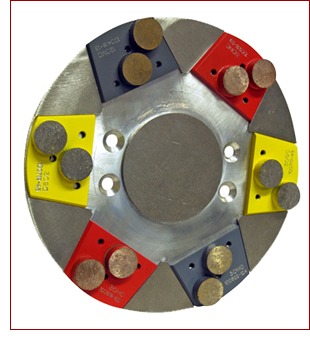

| Grinder Accessories |

EDCO has expanded its Turbo Grinder accessory line with new Quick-Change accessories, which easily slide onto the Turbo Grinders and stay on magnetically. The user simply fastens the quick-change plate onto the machine, and then slides on various accessories as needed. The system eliminates the need to unbolt accessories every time a change is needed. The Diamond-Dot accessories remove coatings and smooth rough concrete surfaces, while the PCD accessories aggressively remove thick coverings. All EDCO Turbo Grinders quickly remove high spots, uneven joints, epoxy, urethane and other difficult coverings from concrete surfaces. EDCO has expanded its Turbo Grinder accessory line with new Quick-Change accessories, which easily slide onto the Turbo Grinders and stay on magnetically. The user simply fastens the quick-change plate onto the machine, and then slides on various accessories as needed. The system eliminates the need to unbolt accessories every time a change is needed. The Diamond-Dot accessories remove coatings and smooth rough concrete surfaces, while the PCD accessories aggressively remove thick coverings. All EDCO Turbo Grinders quickly remove high spots, uneven joints, epoxy, urethane and other difficult coverings from concrete surfaces. |

Mid-grade premium blades, such as the Norton Charger series, bring the operator closer to the application than the fore-mentioned counterpart as the better tier. These blades typically provide improved performance and extended life for medium to large intermittent jobs.

|

|

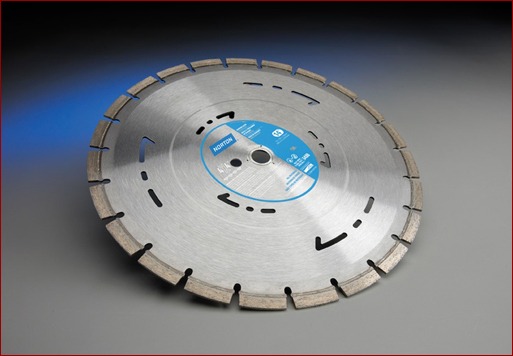

| Norton Silencio Blade |

Then, there is the best innovation tier of blades like our DUO family, 4×4 and Silencio. Blades of this level commonly host patented features to increase productivity and blade life, while furnishing precision in the work. Depending on the blade type, it can be more of an upfront investment, but bring cost down over the blade life. Your work is your livelihood. The blade is an extension of your work. You should always consider how you promote your business.

Blades have come a long way over time from pressing to brazing. More than 25 years ago, Norton introduced the first laser welded diamond blade. The demands of applications continue to force changes in bonds, diamond type and blade cores. Sound dampening is an example of the technology moving the diamond tool industry forward. With laser cut cores to distort the vibrations that cause noise, to epoxy filled sandwich cores, both contribute to softening noise levels.

The request for quieter cutting blades has directed our manufacturing side to seek alternatives to the commonly used methods. Two years ago, Norton introduced the patent pending Silencio diamond blade with two offset cores filled with gel that provided the base to reducing cutting noise by as much as 15 db(A). This is just one solution but it leads to others, like in equipment.

| Product Watch |

Affinity Tool Works has launched the Dtec Diamond Blade product division, which offers three lines of diamond blades: Superior, Contractor and Barracuda. The three lines provide a solution for every type of construction cutting application and budget. Dtec blades are engineered to perform and built to meet the demands of a variety of applications, and are intended to fit a wide range of both gas- and electric-powered saws. Affinity Tool Works has launched the Dtec Diamond Blade product division, which offers three lines of diamond blades: Superior, Contractor and Barracuda. The three lines provide a solution for every type of construction cutting application and budget. Dtec blades are engineered to perform and built to meet the demands of a variety of applications, and are intended to fit a wide range of both gas- and electric-powered saws.

Dtec’s Superior series offers more than 10 blade sizes and is available in segmented and turbo configurations. Both blade edges are an ideal solution for fast, yet precise, cuts on higher end materials like granite, stone, tile and even steel. All Superior blades are built with a reinforced flange, which reduces vibration and noise and, when combined with strategically placed cooling holes, helps prevent warping caused by excessive heat. Consisting of more than 15 blade sizes, the Contractor series offers an option for the price-conscious without sacrificing the performance of a diamond blade. Three different configurations are available to suit a wide range of applications: segmented, continuous rim and turbo. Intended to cut material such as concrete, masonry block and brick, this line is ideal for tradesmen in the general and landscape construction, concrete and masonry industries. Featuring a continuous rim design, the Barracuda series is a premium line that offers the smoothest, thinnest cuts for wet or dry applications. S-slots in the blade prevent heat build-up, extending blade life up to 10-times longer than similar blades. Furthermore, the S-slot design keeps the blade from warping and allows straighter, more precise cuts. Designed exclusively for “beauty cuts,” the Barracuda series is perfect for cutting expensive granite and tile on high-end commercial and residential finish work and remodeling. For more information, visit www.affinitytool.com. |

The desire to reduce the sound pollution resulting from diamond blades on masonry equipment is now outpacing the masonry equipment. We are seeing a rising trend today, with the use of high-speed saws and diamond blades to cut masonry materials. Although this is an efficient solution, this approach sacrifices any benefits gained from diamond blade design technology. The need to reduce saw weight and increase the portability of equipment now requires diamond blades to function with less horsepower. In the practical application of the ideal diamond blade, the maximum cutting efficiency is still the result of appropriate match of diamond and bond to the material cut.

Conclusion

So, you see diamond blades are not “just diamond blades.” No doubt they can look very similar in basic design, but much education is needed with regard to material make up, application and type of machine being used.

Use and/or duplication of this article in whole or in any kind requires prior authorization of intent of use and identification of Saint-Gobain as the source.

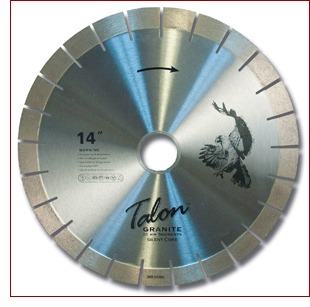

| ??Industry’s Largest Segments From Braxton-Bragg |

Braxton-Bragg’s Talon Array 26mm Silent Core Bridge saw blades are made with the largest segments yet offered by the industry. The blades are designed to cut granite and other hard stones better for longer, saving the fabricator time and money. Talon Array blades will cut granite smoothly and with minimal chipping, providing a consistent cut. Having a smooth starting point after your material is taken from the bridge saw means less steps to achieve your goal. Braxton-Bragg’s Talon Array 26mm Silent Core Bridge saw blades are made with the largest segments yet offered by the industry. The blades are designed to cut granite and other hard stones better for longer, saving the fabricator time and money. Talon Array blades will cut granite smoothly and with minimal chipping, providing a consistent cut. Having a smooth starting point after your material is taken from the bridge saw means less steps to achieve your goal.

Array Technology means the diamonds used on the Talon Array blade are evenly spaced to provide the same quality cut from the first use of the blade to the last. The Array technology combined with the super-sized segments results in a blade that cuts even the hardest stone without causing the fabricator’s saw to draw increased amps. For additional information on the Talon Array 26mm Silent Core Bridge Saw Blade, call 800-575-4401. |