Mixers, Pumps and Delivery Systems

Core Filling With a Masonry Grout Pump

Mason contractors can accomplish structural reinforcement core filling requirements by pumping grout or mortar with a masonry grout pump. Using a masonry grout pump can be beneficial to the mason contractor in several instances, such as:

- Barriers on the job prevent a grout delivery system from being lifted into place

- Freeing up a forklift/telehandler is seen as an advantage

- Labor for bucketing or using grout bags is not an option

- The job volume and equipment budget do not warrant a full-sized concrete pump or grout delivery system

- Desire for portability of a smaller masonry grout pump to the jobsite and use of a self-propelled machine on the jobsite.

Grout pumps used in the masonry field typically are powered by a gas engine (although electric or LP gas power have been used successfully for indoor jobs). The engine powers a hydraulic pump, which extends and retracts a material cylinder. Material is fed into the receiving hopper and forced or “pumped” out of the material cylinder into the material hose connected to the pump. The extend/retract motion of the cylinder is referred to as a “stroke.” The material hose may include various types of fittings and couplings that connect to the pump or any line reducers at the pump discharge. Sections of grouting hose are typically 25 or 50 feet long. A pipe bend otherwise known as a “wall hook” is connected at the end of the hose and is inserted into the block when pumping.

|

|

| Grout hoses in use |

When using a grout pump, some keys to success are worth keeping in mind, namely material mix design, pump priming and taking full advantage of the grout pump’s capabilities.

Material mix design

Material mix design and the use of proper materials are critical for successful grout or mortar pumping with a masonry grout pump. Contractors must be sure that the mix design used with the grout pump does not include aggregates more than 3/8-inch minus pea-gravel (3/8-inch and below). Using rocks larger than this size in the material could clog the pump and material hose.

Masonry grout pumps are compatible with the specification for fine grout as stated in ASTM C476 Standard Specification for Grout for Masonry. This specification classifies fine grout as either “conventional grout (requiring mechanical consolidation by puddling or vibration when placed) or self-consolidating grout (not requiring mechanical consolidation when placed).” The self-consolidating grout owes its automatic consolidation characteristics and high-flow rates to the water-reducing agent included in the mix. High-range water reducers are preferred. ASTM C476 states, “Polycarboxylate-based high-range water-reducing admixtures are best suited to achieve the water reduction and slump flow values required for self-consolidating grout.

The related specification ASTM C404 Standard Specification for Aggregates for masonry grout further clarifies the actual dimensions of aggregates in a fine grout mixture by stating that all aggregate must pass a sieve test at 9.5mm/3/8-inch minus for the grout to be classified as fine grout.

Proper mix design should be specified when ordering material from ready-mix if using a grout pump. Masonry grout pumps are designed to pump Portland cement, blended cements, sand and fine grout aggregates, non-shrinking grouts, pre-bagged mortar, pulverized lime/hydrated lime, quicklime, fly ash, pozzolan and slag – provided all materials are proportioned in the proper amounts with adequate water content. The inclusion of any admixtures, such as water reducing or air entraining, may be determined by the building code or contractor. These admixtures may be useful in ensuring overall “pumpability” of the material used with the grout pump. Some all-in-one admixtures claim to offer “water reduction, plasticizing, air entraining and gelling” in addition to featuring “higher flexural psi, workability, excellent bonding, freeze-thaw protection, easier pumping, high-range water retention and maximum ASTM C-494 and C-260 requirements” (Kel-Crete Admixture).

When batching onsite using a high-strength grout or mortar, be sure to evaluate the aggregate size, first and foremost, to ensure that the mix does not include aggregates more than 3/8-inch minus. Also, test the material by squeezing a small amount of material in your hand; it should all squeeze out between your fingers and leave no aggregates or clumps. All mixtures must be slick to pump through the grout pump, material line and hose. If not slick, the material could clog the hose.

Large clumps caused by dried materials could also clog the pump or material hose. The addition of more fines (sand) to suspend aggregates, cement, plasticizer or lime also could improve the material mixture. Pay close attention to water content in the mixture, and ensure it does not separate out from the other materials. Too much water can, depending on the material, cause sand to separate from cement, preventing the material from performing its function as structural reinforcement in the core filling process.

| Product Watch |

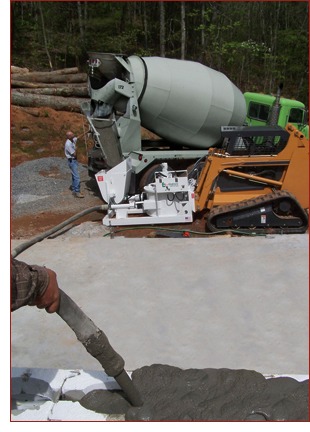

Blastcrete Equipment Co.’s Model RD6536 Skid Steer Pump Attachment features a universal design compatible with any skid steer. The three-inch hydraulic squeeze pump is ideal for ICF, block fill, form and pour, driveways, basements and various shotcrete applications. Blastcrete Equipment Co.’s Model RD6536 Skid Steer Pump Attachment features a universal design compatible with any skid steer. The three-inch hydraulic squeeze pump is ideal for ICF, block fill, form and pour, driveways, basements and various shotcrete applications.

With the ability to pump grout materials, 3/8-inch shotcrete and 3/4-inch structural concrete mixes, the RD6536 is a fast, efficient solution for contractors performing a variety of concrete and shotcrete applications. The unit offers a variable speed of 0-25 cubic yards per hour. Vertical pumping distance reaches 50 feet with the use of a rubber delivery line, while horizontal distance can reach up to 250 feet. A hydraulic agitator is included in the receiving hopper. The agitator’s continuous motion keeps the mix well-blended, ensuring aggregate and sand stay evenly suspended throughout the mix. Not only does this result in high-strength concrete, it keeps the aggregate and sand from settling to the bottom of the hopper and clogging near the suction area. To relieve pressure build-up clogs and eliminate potential damage to the pump, the RD6536 can be run in both forward and reverse. Hydraulically powered controls are located on the pump and also operate both agitator and pump speed. Maintenance requirements for the RD6536 are simple, and clean-up takes just minutes. The steel-constructed unit is designed to prevent any concrete from coming in contact with the pump’s moving parts, further reducing maintenance concerns and ensuring a long service life. The primary wear part, the rubber pumping tube, can be easily replaced on the jobsite in about 20 minutes. Using just water and a sponge ball, the pump can be cleaned out in about five minutes.

Visit www.blastcrete.com for more information. |

Priming the pump

Mason contractors interested in using a grout pump for grouting walls should be aware of all recommended procedures for setting up the grout pump on a job. Most of these procedures are fairly basic. One procedure – priming the pump – is especially worth mentioning. For masonry grouting and mortar pumping (especially when using 3/8-inch minus pea gravel in the mix), it is crucial to prime the pump and hose before starting the job.

Priming involves the following simple steps:

- Elevate the end of the material hose higher than the top of the material hopper, while pouring water into the hopper and pumping it through the entire pump and length of hose

- Drain the water by lowering the material line down lower than the pump discharge (outlet)

- Add either a neat cement slurry or hose primer/pumping aid to the pump hopper, and then insert the end of the hose into the material hopper (be sure primer is compatible with material to be used)

- Re-circulate the slurry/primer by pumping a few strokes through the hose and back into the hopper.

After successful priming of the pump, connect any remaining lengths of hose, and add the material for core filling to the grout pump’s material hopper. Circulating the material through the hose and back into the hopper is recommended, until you are sure the material is correct.

Making full use of the grout pump: hoisting

In addition to pumping grout or mortar for core filling, contractors now are using grout pumps for hoisting mortar to the scaffolding. This technique allows the contractor to move mortar up the scaffolds onto the floor levels and into a trough to be used by the masons laying the block. Hoisting mortar with the grout pump can eliminate waiting time that masons often experience on a job. On many jobs the masons are constantly waiting for mortar to get to them, because cranes are being tied up performing double duty – lifting block and mortar into place. Use of the grout pump to hoist the mortar takes some of the load off of the crane. This allows the mason contractor to more efficiently distribute materials where they are needed most. The use of two pumps on the jobsite may even allow the contractor to grout the walls and lay block at the same time with the same material

For more information, call 513-321-2950 or visit www.airplaco.com.