Dust Collection

The Big Deal About Silica Dust Collection

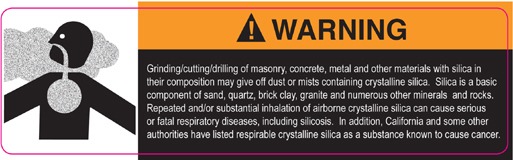

Silica is the second-most common compound on earth. It is found in sand, minerals, granite, sandstone, flint and slate. It also can be in soil, mortar, plaster and shingles. The cutting, breaking, crushing, drilling, grinding or abrasive blasting of these materials may produce fine silica dust.

|

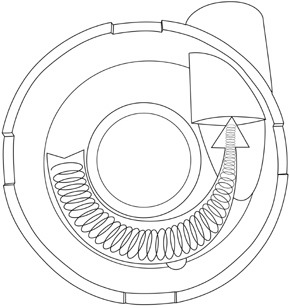

Cyclone Technology

The MK Diamond IXL Vacuum Shroud, for concrete and surface grinding dust control, has been designed to utilize the air velocity created by the rotating grinding wheel to efficiently channel dust particles away from the work surface. The IXL Shroud’s unique snail-shape design creates a higher centrifugal force that expels the dust particles away, in cyclone fashion, from the grinding cup wheel into the vacuum hook-up port. This technology improves removal of particles, which further enhances the grinding process. Controlling dust is important for health and environmental issues, and this shroud addresses those concerns. The IXL Shroud can be used with a vacuum system or with an approved bag if a vacuum is not available, thus reducing risk of respiratory problems and saving time during clean up. |

|

With the advent and increased use of dry cutting, drilling and grinding of concrete and masonry material in construction, we often see workers operating in a cloud of dust with no respiratory protection or safety measures to prevent airborne dust. Exposure levels in settings like construction sites are highly variable for airborne silica dust, which poses a significant risk to workers.

Workers in these construction environments are at high risk of developing silicosis, a serious lung disease caused by the accumulation of silica dust in the lungs. Even today, many workers are not aware that common building products such as clay bricks, concrete, tiles and cement products contain silica. When these building products are cut, drilled or ground using diamond blades or cup wheels, they create fine particles of silica in the air. When small silica dust particles are inhaled, they can embed themselves deeply in the lungs, where oxygen and carbon dioxide gases are exchanged. There, the lungs cannot clear out the dust by mucous or coughing. The silica dust causes the formation of scar tissue, thus reducing the lungs’ ability to take in oxygen. Many workers with silicosis develop other health problems such as tuberculosis and lung cancer. There is no cure for silicosis. Silicosis is the most common occupational lung disease worldwide.

Controlling silica dust at work

The only effective protection against silicosis is the prevention of silica dust in the air. Employers must take measures to ensure that workers are not exposed to silica dust. There a number of simple control measures that can be taken to effectively reduce the amount of airborne silica.

Tools causing dust, such as grinders and saws, should be fitted with water attachments or dust extraction devices. Where possible, water is the preferred method for elimination of dust.

Tools fitted with water attachments are the most effective in suppressing dust. Using water during cutting or drilling can reduce the amount of dust by as much as 75 percent.

When grinding concrete or other masonry materials, a shroud with a vacuum attachment should be used. Shop vacuums do not provide adequate protection from the recirculation of fine particles of silica dust in the air and should not be used. Vacuums that have a HEPA Filter are the preferred method for collecting dust.

If dry grinding is performed, regular vacuuming and wet sweeping of floors also will help to remove settled dust during these operations. This practice is particularly important to stop dust from being kicked back into the air.

|

OSHA on Silica Control OSHA has released “Controlling Silica Exposures in Construction” (www.osha.gov/Pulibcations/3362silica-exposures.pdf), which is a guidance document that addresses the control of worker exposure to dust containing crystalline silica, known to cause the lung disease silicosis. The publication, intended to assist employers in providing a safe and healthful workplace, includes methods for controlling silica such as wet cutting during construction operations. Vacuum dust collection systems also effectively control silica by drawing dust particles away from the worker’s breathing zone and depositing them into a filtered dust-collection chamber. Employers should conduct periodic monitoring of silica exposure by testing air samples at the construction site to determine if the level of silica in the air exceeds the permissible exposure limit (PEL) outlined in the construction PEL standard. As one of OSHA’s areas of emphasis, the agency has developed standards for silica to assure work practice controls are effective. For more information, visit www.osha.gov/SLTC/silicacrystalline/index.html. |

Wear disposable or washable work clothes, and shower if facilities are available. Vacuum dust off your clothes or change into clean clothing before leaving the worksite. Do not take contaminated clothes home.

Do not eat, drink or smoke in areas where crystalline silica dust is present.

|

Learn More For more information about respirator programs, including which respirators have received NIOSH approval as safe and effective, visit the NIOSH Web site, www.cdc.gov/niosh/npptl/topics/respirators. All these preventive measures should not be looked at in isolation, but in combination with each other. For more information, visit www.osha.gov/SLTC/silica California and some other authorities have listed respirable crystalline silica as a substance known to cause cancer. For more information, visit http://oehha.ca.gov/prop65/law/P65law72003.html and www.dir.ca.gov/Title8/sub4.html. |

Wash your hands and face outside of dusty areas before performing any of these activities.

Posters and signs warning of the presence of silica dust should always be prominently displayed at any work site. Quarterly “Tail Gate Talks” should be conducted on the dangers of silica exposure so that all workers have a complete understanding of how to prevent increased exposure.

The use of Respiratory Protective Equipment should be considered as a last resort when all other preventative solutions have been put in place and silica dust exposure continues to be an issue. Respiratory Protective Equipment can vary, so make sure that the proper equipment is being used and fitted correctly to each worker. Workers must be trained in the proper way to use a respirator and must understand the health reasons for always wearing it. Wear only a N95 NIOSH certified respirator, if respirator protection is required. It is mandatory to have a written respiratory program in place if any kind of protective equipment is being used.