January 2009

Tools

Tools of the Hardscaping Trade

Less maintenance, more productivity and additional benefits define

today’s hardscaping tools and equipment.

Stone Construction Equipment Inc. ??? Mud Buggy

Manufacturers of hardscaping tools and equipment say that their latest models are helping contractors save time and money, while increasing jobsite productivity.

“What we try to do is make the job easier for the contractor,” says Steve Cook, sales and marketing manager for Kraft Tool Co. in Shawnee, Kan. “We want to make tools that are easy to use on the job, keep bricklayers laying for a longer time, and are easier on their backs.”

Material hauling made easy

Although the Mud Buggy from Honeoye, N.Y.-based Stone Construction Equipment Inc. was primarily intended to shuttle cement from concrete trucks to the point of use, the versatile machine also hauls hardscaping materials, says Ed Varel, senior product engineer for the company. One Mud Buggy equals several hardscaping laborers with wheelbarrows.

“The Mud Buggy saves wear and tear on the operator [that are] associated with lifting loads with wheelbarrows and moving materials manually,” Varel says. “The larger the Buggy, the more productivity. There are also savings involved with servicing the machine. Unlike other machines, you don’t need to empty the drum manually to remove the engine cover.”

|

|

| Stone Construction Equipment Inc. ??? Steel Stakebed |

In addition to the standard 16-cubic-foot polyethylene tub and the 21-cubic-foot steel tub, Stone Construction Equipment offers a steel stakebed and other tubs for collecting and hauling debris, block, gravel and other hardscaping materials.

“The stakebed conversion option for the Buggy was specifically designed for contractors looking for a dump truck-type bed with the stakebed’s swing door at the front for materials that do not dump out of a bucket as easily as concrete,” Varel explains, adding that a foot pedal lets the user control speed, direction and steering without removing his hands from the handles.

Low-maintenance, enduring carbide tools

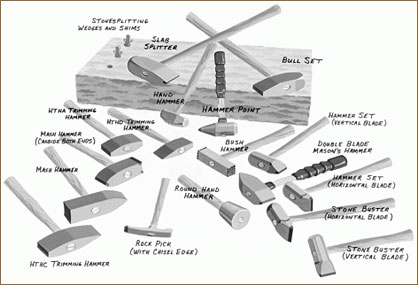

Trow & Holden Inc. in Barre, Vt., has brought several new carbide-tipped hand tools to the market during the last few years, including rocko chisels, hand points, hand sets and mason’s chippers.

Carbide tools are hard, so they’re perfect for working with tough hardscaping pavers and stone, says Lauren LaMorte, VP for Trow & Holden. “Carbide is harder and maintains its shape much longer than steel,” LaMorte says. “That means there’s less maintenance for the contractor.”

|

| ??Trow & Holden Carbide tools |

She says grinding carbide tools takes more expertise. Unlike steel tools, which are liquid cooled during grinding, carbide tools are air cooled. The upside is that contractors don’t have to sharpen them as frequently as steel tools.

“They take longer to get dull, so contractors don’t have to grind them as often,” LaMorte says, adding that carbide tools have longer life spans, which offsets the higher cost of carbide.

“Carbide outlasts steel tools significantly,” says Norm Akley, Trow & Holden president. “Depending on the stone, overall, you can expect carbide to outlast other tools by up to 30-to-1.”

Hardscaping contractors can use the carbide chisels for trimming and splitting, LaMorte says. Knocking down high spots with a carbide hand point and a striking hammer makes the stones fit more snuggly.

| ?????? |  |

| Kraft Tool ??? Five Piece Screed Set |

|

| ?????? |  |

| Kraft Tool ??? Aluminum Extruded Level |

Leveling tools for faster base installs

New levels and screeds from Kraft Tool enable hardscaping contractors to install bases for pavers faster and easier. The company has a new one-inch X four-inch screed set, which includes five screeds ranging in length from 1.5 to six feet.

“They’re in different lengths to smooth out a sand base,” Cook says. “Basically, the sizes adapt to different obstacles on the job, like steps or an air conditioner that you have to work around.”

The screeds work well for leveling bases in short runs and irregularly shaped paths and walkways, he says. Kraft Tool is also offering heavy-duty levels up to 96 inches long.

|

|

| Kraft Tool ??? Buckeye Straightedge |

“These are aluminum extruded levels, so they’re strong and stay straight,” Cook says. “These are good levels to use when installing the base on those landscaping jobs.”

New in 2008 was the Buckeye Straightedge, a high-grade aluminum straightedge with a level vial built into the wooden handle. The adjustable level allows hardscaping contractors to easily create a grade when laying a base.

“The level is adjustable to change the angle of the base so water can drain off,” Cook says. “When you come off steps or have long runs, you want the water to drain.”

| ?????? |  |

| Extracting and Alignment Bar |

|

| ?????? |  |

| Paver Extracting Tongs |

Removing and straightening pavers

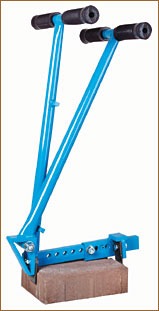

Removing or straightening damaged or dislodged hardscaping materials can be difficult, especially if the pavers have been set for a long time. Bon Tool Co. in Gibsonia, Pa., offers a couple of tools to make the job easier. Tempered steel blades on the tools fit around the hardscaping materials to move it.

“These are great tools for repair work,” says John Wight, VP of sales and marketing for the company. “They fit around the paver, so you don’t have to try to get it out with a screwdriver. The tools also let you stand up to work instead of working on your hands and knees.”

Paver Extracting Tongs let hardscaping contractors remove a single paver without disturbing surrounding pavers. Adjustable jaws open up to 11 inches to grab most paver sizes, even those with irregular shapes.

The Extracting & Alignment Bar allows hardscaping contractors to remove or reset pavers or stone. The offset handles help wedge the tool in place between pavers.

“It’s really easy to grip the paver to remove it or reposition it,” Wight says.

Efficient hand tools

The Hard Cap Safety Tool line from Baltimore Toolworks Inc. in Baltimore isn’t brand new; it was introduced about two years ago. But new tools have been continually added.

“We have a complete range of products for masons and hardscaping contractors,” says Harry “Downie” McCarty, company owner.

While the reinforced polymer on the tool head and body reduces noise by 80 percent and shock by 90 percent, McCarty says enlarging the striking surface, or head, 2.5 times and giving the chisels a sharper edge makes the tools more efficient.

“We slightly modified the cutting edge to make it more aggressive,” McCarty says, noting that the wider head encourages users to strike the tool harder. “We found that the tools were outperforming standard chisels. They were 15 percent to 20 percent more efficient. We noticed that the user had more confidence when they hit, so they hit with a wider arc and hit harder. They were literally hitting 15 percent to 20 percent harder.”

![]()

Baltimore Toolworks ??? Hard Cap Safety Tool

The larger head also prevents mushrooming and eliminates flying chips, making the tool safer, McCarty says. “The tools save your knuckles and your fingers.”

|

![]()