Personal Safety

Regardless of the scope, profit margin or difficulty of a project, cutting corners with regard to personnel safety can never be justified. A good-faith effort to keep employees safe makes solid business sense and ensures protection of your company’s bottom line.

Regardless of the scope, profit margin or difficulty of a project, cutting corners with regard to personnel safety can never be justified. A good-faith effort to keep employees safe makes solid business sense and ensures protection of your company’s bottom line.

By K.K. Snyder

Whether it’s fall protection, respiratory care or eyesight and hearing safety, knowing what is required of employers and where to obtain quality safety gear are first orders of business. And, having the equipment on hand isn’t enough; employers and their crews also must take responsibility for using the equipment properly in order to get maximum benefits.

The masonry industry, and others affected by OSHA regulations, was boosted in 2004 when the House passed four bills, sponsored by the Workforce Protections Subcommittee, which were designed to improve workplace safety, enhance business competitiveness and foster more job creation to spur the economy.

The measures ensure OSHA enforcement efforts are fair for small businesses that make good-faith efforts to comply with all health and safety laws. These reforms improve worker safety by making it easier for employers to work voluntarily and proactively with OSHA to ensure safe and secure workplaces.

With just 4,000 compliance officers at the federal and state levels, OSHA is greatly outnumbered compared to the number of contractors in the country. “That’s the good-faith piece,” says Stew Burkhammer, who, after 40 years with the agency, recently retired as OSHA’s director of construction services. “When you put all of them together, that’s not a lot of inspectors to cover all the sites.”

Burkhammer says inspections are done for three purposes, including generally scheduled inspections and inspections following a complaint being filed or a jobsite fatality.

“If they fall within certain criteria, we subtract based on good faith by the employer,” says Burkhammer. “They can have their fine reduced quite a bit if they’re identified as a good guy, and they try to correct the violation.”

Violations in the masonry industry can include not using proper eye and ear protection, not using respiratory equipment when dry cutting block or brick, or not using fall protection when erecting or disassembling scaffolding.

Breathing right

One personal safety issue among masonry crews is respiratory protection, says Bill Parsons, a construction safety education specialist with OSHA, who has 33 years of experience as a certified safety professional. Among recent changes to OSHA standards affecting the masonry industry are those related to personal protective equipment (PPE) for respiratory safety.

Workers exposed to substances such as silica or the hexavalent chromium found in wet and dry Portland cement are required to wear respirators. Breathing in high levels of hexavalent chromium can cause irritation to the nose and throat. Repeated or prolonged exposure can cause sores to develop in the nose and result in nosebleeds. Some employees become allergic to hexavalent chromium, and inhaling chromate compounds can cause asthma symptoms such as wheezing and shortness of breath.

Workers exposed to substances such as silica or the hexavalent chromium found in wet and dry Portland cement are required to wear respirators. Breathing in high levels of hexavalent chromium can cause irritation to the nose and throat. Repeated or prolonged exposure can cause sores to develop in the nose and result in nosebleeds. Some employees become allergic to hexavalent chromium, and inhaling chromate compounds can cause asthma symptoms such as wheezing and shortness of breath.

These eyes

In addition to OSHA requirements, individual company policy can also dictate safety requirements for employees, says Jerry Painter, president of Painter Masonry Consultants and a 40-year veteran of the industry.

“Our company policy is that every new hire gets eye protection and safety glasses,” says Painter. “If they lose them or abuse them, they are required to buy their own, unless it’s a hazard they’re having to deal with or a specialized situation.”

“Our company policy is that every new hire gets eye protection and safety glasses,” says Painter. “If they lose them or abuse them, they are required to buy their own, unless it’s a hazard they’re having to deal with or a specialized situation.”

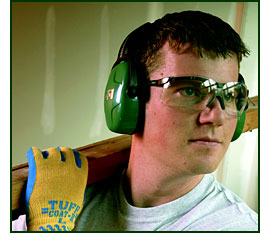

The type of eye protection used can range from simple safety glasses for standard tasks to a full-face shield for added protection during chipping, grinding or sanding. But if you’re working for a construction manager or general contractor with a company policy that the project requires 100 percent safe eyewear, all employees are required to walk on the jobsite wearing safety glasses, regardless of the type of work they are doing.

“Goggles are very difficult items to work with, because [masons] have problems with them fogging up and sweating inside them in warm climates,” says Painter. “When they fog up, they aren’t easily cleaned and will scratch. We try to stay away from goggles because of ventilation and safety.”

Can you hear me now?

With regard to hearing protection, most of his crews use the disposable earplugs. “But you have to stay after them about using them,” he adds. “If they are working in an enclosed area with chipping devices, they use full earmuff protection.”

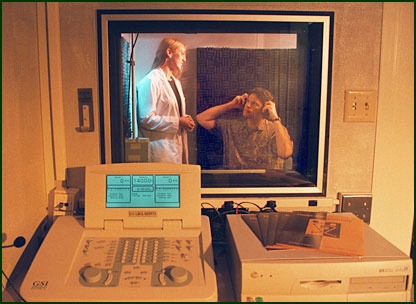

The biggest issue with hearing protection products is getting the employees to use them correctly, says Andy Vermiglio, an audiology researcher with House Ear Institute. He says that, while the foam plugs have a “pretty good” attenuation rating (the rating at which they reduce noise), leaking occurs if they aren’t used correctly.

“They have to be properly inserted,” he says with regard to the inexpensive foam-type plugs widely available. “There is a particular way to wear those ear plugs. They have to insert them fairly deep inside the ear canal, so they might not be appropriate for someone with a tiny ear canal.”

The best ear protection is to double up, says Vermiglio, meaning workers can wear the foam inserts as well as full earmuffs. Another option is custom-molded earplugs that are fitted to the individual and are easier to insert deeply into the canal.

Not using hearing protection can result in tinnitus, or ringing of the ears, which can causes sleep loss and depression, according to Vermiglio. Also, inner ear damage can result in high-frequently hearing loss, which is significant since in speech, high-frequency sounds are those made by consonants.

“That’s when a seasoned worker will say, ‘You don’t have to yell, I can hear you,’ but they can’t understand you because everything sounds muffled,” Vermiglio says, noting the dangers of irreversible hearing loss. “And many people become candidates for hearing aids. Whereas glasses might restore perfect vision, hearing aids will get you part way there, but will never replace a normal set of healthy ears.”

Employees in the construction industry must also consider what they are doing off duty. Listening to a blasting car stereo, running power tools or operating a speed boat adds to their overall noise dosage when they would be better off giving their ears time to rest.

To ensure earplugs are providing acceptable attenuation for employees, Sperian Hearing Protection recently launched VeriPRO, a new software program that determines if the hearing protection fits the worker, if it’s being used properly and whether it’s providing adequate protection.

“We can also offer one-on-one training to insert earplugs or help them select another type of hearing protection,” says Renee Bessette, marketing manager for Sperian Hearing Protection. “One type of earplug does not fit all people.”

Foregoing the fall

Fall protection is mandatory by OSHA regulations for anyone working at a height of six feet or higher. The American National Standards Institute, which recently made a major change regarding snap hooks on fall protection equipment, has set requirements as well. Prior to the change, the gate of a snap hook had to support just 220 pounds, and the side had to support 350 pounds. Now, the gate must support 3,600 pounds, says Scott Rousseau, VP of Web Devices, a vendor of personnel safety equipment.

“That was a major shakeup that went into effect last November,” Rousseau says. “Everyone is scrambling around in the industry to determine what hooks they’ll use, what line and what will suit the end user best.”

Employers purchasing fall equipment for their workers can spend anywhere from $50 to more than $100, adds Rousseau, “depending on how many bells and whistles they want.”

Guidelines for fall protection are specific, even requiring that the thread used to sew the webbing together be of a contrasting color for purposes of inspection. Skimping on any of these safety requirements is a bad idea, says Rousseau. In fact, about two fall-related deaths occurred on jobsites each day in 2006, and the leading cause of injury and death in the workplace is falling.

“You don’t need fall protection unless you fall, but accidents continue to happen and it’s absolutely insane not to have it even if the government didn’t require it,” says Mark Willingham, president of Web Devices, adding that people who need to work will do it with or without protection.

“A lot of small contractors don’t want to have to buy this and this and this; they just want to be in and out in a hurry,” Willingham says. “But if they’re sued, they file bankruptcy and start over under another name, rather than paying the lawsuit. It’s just not fair to employees not to [provide the protective equipment].”

Again, individual company policy might set standards even higher than those required by OSHA. For instance, while OSHA doesn’t require guardrails on scaffolding unless working at a height of 10 feet or higher, Skanska USA Building Inc. requires employees to use rails at six feet and higher, says David B. Korman, an environmental, health and safety director for the international construction company. Skanska also requires workers to wear high-visibility clothing, such as reflective vests in orange or lime, as an additional safety measure.

“It’s really pre-planning,” he says, regarding overall jobsite safety. “It’s planning and making it a part of the work day to get workers involved in protection and safety to identify hazards and what can be done to control and mitigate those hazards.”

Korman, who is currently overseeing the massive New Meadlowlands Stadium project in New Jersey, says his company goes so far to protect workers from injury that they start each and every morning with a 10- to 15-minute group stretch and flex session.

“It’s a stretching routine to get the body moving and stretch out muscles, especially in cold weather. I think that’s been proven to be a major benefit in reducing the likelihood of soft tissue injuries,” he says, noting the financial benefits of keeping employees safe, including lower premiums for workers’ compensation insurance.

“It’s a stretching routine to get the body moving and stretch out muscles, especially in cold weather. I think that’s been proven to be a major benefit in reducing the likelihood of soft tissue injuries,” he says, noting the financial benefits of keeping employees safe, including lower premiums for workers’ compensation insurance.

“The entire insurance industry’s costs have gone up over the years, but workers’ compensation, is something, as high as it is, that can certainly be reduced by being safe,” says Korman, adding that workers have a right to a safe environment. “Insurance companies have an interest in working hand-in-hand to put safety programs into place.

“Every worker has a right to go home to loved ones at the end of the day,” he continues. “As a country, we spend too much time looking at OSHA as the bad guy. We’re trying to create a culture where every person on the jobsite feels like they’re cared about and looks out for one another and for themselves.”

Better safe than sorry

Korman says staying abreast of safety rules and regulations doesn’t require employing a full-time safety officer. Scores of resources are available through trade associations, small business organizations or consultation services. In addition, insurance brokers for workers’ compensation often provide safety courses for their clients.

“There are really so many more resources available than there used to be,” he says. “But there still are more lawsuits or projects being shut down due to serious injury. Safety doesn’t cost money; safety saves money. Unfortunately, people think of it the other way around.”

Other jobsite safety issues for which employers provide protection are the repetitive motion disorders from lifting brick and block, as well as the risks of lifting in general. Many employers and craftsmen find assistance through their unions. Rather than relying on individual contractors to be proactive, unions will invest in resources for members, provide training and, in some cases, actually provide respiratory protection and other equipment, says Korman, who also serves as administrator of Construction Practices Specialty for the American Society of Safety Engineers.

In addition to protection from sight, hearing and fall hazards, essentials for safety on the jobsite include hard hats, gloves, appropriate footwear and protective clothing. Companies such as Sperian, Web Devices and MSA offer full lines of personnel protection equipment and stay abreast of the latest government regulations with regard to their products.

“Most legitimate, good contractors are going to do the best they can to provide a safe environment for employees,” says Painter. “In this day and age, there is not an abundance of skilled craftsmen, good masons. It’s an economic thing, because I cannot afford to lose any of my masons or laborers to injury.

“My biggest fear is not OSHA; it’s not having these workers on the job,” he says. “The last thing we need is a time-out injury that will take anyone off the worksite. It’s an economic disaster.”

K.K. Snyder is an Albany, Ga.-based freelancer writer and editor. She can be reached at kkondeadline@hotmail.com.