January 2009

Pavers

Pavers in Action

Winners from the 2008 BIA’s Brick In Architecture Awards Competition demonstrate how clay pavers epitomize the principles of New Urbanism.

| ?????? |  |

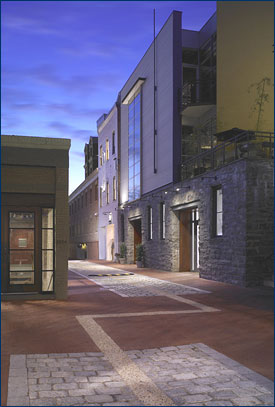

| Cady’s Alley, Washington, D.C. |

Genuine clay pavers have been used in on-the-ground applications with outstanding success since early Colonial days. Color retention and compressive strength that surpass concrete-based segmental paving systems make it easy to understand why architects and designers keep specifying authentic, versatile, genuine clay pavers.

Clay pavers are also instrumental in helping architects and designers with green building design and sustainable strategies. Clay brick is the most sustainable green-building material, with its combination of natural ingredients, low-maintenance requirements, extreme durability, little on-site construction waste, and ability to be recycled or re-used.

Additionally, flexible or permeable clay pavements can reduce storm-water runoff and filter pollutants. Light-colored clay pavers can reflect a significant amount of solar energy, thereby reducing the heat island effect associated with some urban areas. Flexible clay pavements allow relatively easy access to utilities or services that lie beneath the pavement, and the surface can often be restored with the original materials with no change in appearance.

Clay pavers can play a crucial role in projects that incorporate the principles of New Urbanism, a multidisciplinary approach to restoring walkable, neighborhood-based developments to our communities.

Shining examples

Since 1989, the Brick In Architecture Awards have been one of the country’s most prestigious awards competitions featuring clay bricks. Architectural and design firms from around North America enter their best projects to be judged by a jury of their peers.

As the winning projects from the 2008 Brick In Architecture Awards “Paving & Landscape Architecture Design” category demonstrate, the use of genuine clay pavers helps transform underutilized structures and blocks into vibrant, pedestrian friendly, streetscape destinations that enrich the life of community residents and visitors.

|

|

| Cady’s Alley, Washington, D.C. |

Cady’s Alley, Washington, D.C.

Award: Best In Class

Installation System:

![]() Bituminous Setting Bed on Concrete Base

Bituminous Setting Bed on Concrete Base

Manufacturer:

![]() Glen-Gery Corp.

Glen-Gery Corp.

Landscape Architect:

![]() Landscape Architecture Bureau

Landscape Architecture Bureau

Paving Contractor:

![]() GT Contracting Corp.

GT Contracting Corp.

In the Georgetown neighborhood of our nation’s capital, a single developer issued a daunting design challenge: Convert a number of small, disjointed parcels on an historic city block into a unified, hip, mixed-use destination. Five different architectural firms were commissioned to design the buildings. Together, they created a combined pedestrian, retail and residential space where the major open area throughout the parcels is Cady’s Alley, a historic passageway in Georgetown’s industrial past and now one of the “hottest” shopping destinations in the nation’s capital.

Cady’s Alley presented important design considerations. To start, it is different from other “streets” in Georgetown. The streets drain to the sides, while alleys drain to the center. With this in mind, the drainage section of the alley seeks to dramatize the passage of water down the centerline to carry the water to the alley’s ends.

Additionally, it was important the designers to create the alley in such a manner that its historic character and status were respected and celebrated, although no original paving materials remained in the area. Following the example of the brick and cobblestone alleys throughout Georgetown, the decision to use brick grounded the newly designed alley to its historic past.

Third, it was necessary for the alley to serve as a pedestrian zone as well as allow for heavy vehicles to make deliveries and remove trash. To facilitate these divergent uses, the sides of the alley were paved in brick turned on edge in mimic of a sidewalk. This edge-laid brick deepens the paving, making it stronger for inevitable truck traffic, while also making the paving pattern more interesting and of smaller, more appropriate scale for pedestrians.

Today, the redeveloped Cady’s Alley successfully blends function and form, creating a hardscape that properly reflects the spirit of its storied, historic setting.

|

|

|

| Marion Street Streetscape, Oak Park, Ill. |

Marion Street Streetscape, Oak Park, Ill.

Award: Gold

Installation System:

![]() Sand-Setting Bed on Concrete Base

Sand-Setting Bed on Concrete Base

Manufacturer:

![]() Whitacre-Greer

Whitacre-Greer

Landscape Architects:

![]() The Lakota Group

The Lakota Group

Paving Contractor:

![]() LPS Pavement Co.

LPS Pavement Co.

To recast downtown Oak Park as an economically vibrant shopping, dining and gathering destination for the region, the village of Oak Park decided to remove a 1970s-era pedestrian mall in its downtown business district. At the same time, the village kept an adjacent street as a pedestrian mall and reopened adjacent and adjoining streets to vehicular traffic. Thus began the Marion Street Streetscape project: a nationally acclaimed testament to New Urbanism and visionary planning practices.

Village officials and the streetscape committee decided that the pedestrian mall conversion should create a unique space that would rival any other streetscape project in Chicagoland. With this in mind, the design team specified all natural materials such as genuine clay pavers, as well as green-building design principles, so that the new project not only would stand the test of time, but also would be as environmentally friendly as possible. With extreme durability and sourced through local manufacturers, clay brick pavers were a strong contributor to the sustainable practices used on this project.

The outcome of this project is nothing short of spectacular. The clay brick pavers provide a pedestrian friendly environment while easily accommodating the vehicular traffic necessary for the vitality of the area. With an overwhelming positive response from the community, the new streetscape will be a showcase for the village for decades to come.

|

|

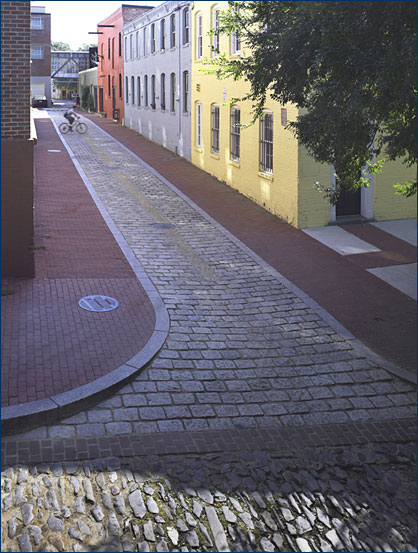

| Downtown Streetscape Improvements, Durham, N.C. |

Downtown Streetscape Improvements, Durham, N.C.

Award: Silver

Installation Systems:

![]() Sand-Setting Bed on Concrete Base;

Sand-Setting Bed on Concrete Base;

![]() Sand-Setting Bed on Aggregate Base

Sand-Setting Bed on Aggregate Base

Manufacturer:

![]() Pine Hall Brick Co.

Pine Hall Brick Co.

Landscape Architects:

![]() Kimley-Horn and Associates

Kimley-Horn and Associates

Paving Contractor:

![]() Valley Crest Landscape Development

Valley Crest Landscape Development

As a result of significant interest in the New Urbanism movement, community officials in Durham, N.C., put forth a plan to improve the streetscapes in the downtown corridor. The idea was to make downtown more pedestrian, bicycle and overall transportation friendly, in an effort to attract residents, consumers and visitors. The ambitious project creates an environment of new offices, homes and business from existing buildings and urban centers. As part of this initiative, streets and sidewalks were reconstructed using genuine clay pavers.

|

|

| Downtown Streetscape Improvements, Durham, N.C. |

The city undertook this revitalization with an advantage over other cities. Many of the older buildings, especially tobacco factories and warehouses, were all made of brick and were still structurally sound. To blend with the existing architecture, clay pavers were specified to provide a visual foundation that drew the eye naturally from the red brick of the street level to the red brick of the surrounding restored buildings.

On a practical level, clay pavers were used because of their durability, low maintenance and versatility. For example, clay pavers are naturally colorfast and will not fade over time, unlike other segmental paving materials. Clay pavers also comply with the Americans with Disabilities Act requirements and can be easily removed for underground maintenance and repair. Clay pavers work extremely well in both pedestrian and vehicular applications, and the variety of available installation systems allows the streetscape to attain a unifying and beautiful look. regardless of the conditions of the surface and/or soil underneath the pavement. Put together, this combination of durability, flexibility and versatility leads to superior long-term economic value.

|

|

| Downtown Streetscape Improvements, Durham, N.C. |

The visually pleasing aesthetics and functionality of brick pavers has helped set downtown Durham apart from surrounding communities. Residents have embraced the redevelopment, and the pedestrian friendly design has successfully attracted more interest and investment in the downtown neighborhood.

American Tobacco Campus Historic Redevelopment, Phases I and II, Durham, N.C.

Award: Bronze

Installation System:

![]() Sand-Setting Bed on Aggregate Base;

Sand-Setting Bed on Aggregate Base;

![]() Sand-Setting Bed on Existing Concrete Base;

Sand-Setting Bed on Existing Concrete Base;

![]() Bituminous Setting on Concrete Base

Bituminous Setting on Concrete Base

Manufacturer:

![]() Pine Hall Brick Co.

Pine Hall Brick Co.

|

|

| American Tobacco Campus Historic Redevelopment, Durham, N.C. |

Landscape Architects:

![]() Smallwood, Reynolds, Stewart,

Smallwood, Reynolds, Stewart,

![]() Stewart & Associates, Inc.

Stewart & Associates, Inc.

Paving Contractor:

![]() Valley Crest Landscape Development

Valley Crest Landscape Development

For decades, attempts to revitalize the old industrial American Tobacco Historic Campus into a thriving, mixed-use development had proven less than successful. In fact, many in the community thought it would be more cost effective to tear down the old plant, which dates back to 1874, and rebuild. However, in early-2002, a local company chose to follow a vision and invest in its community in order to preserve and reincarnate a significant part of history on which the community was built.

The major aesthetic goal for this project was to create an active exterior environment that turned the campus into an exciting place, while preserving its historic character. Selected for its ability to unify the redevelopment, brick with a modern color blend was used as the primary building material. This blend of colors picked up the subtle color influences of the surrounding individual buildings. Because of its modular size, the design team was able to create classic patterns with bold geometry fitting of an old industrial campus. In addition, brick walls, walks and bridges connect the surfaces and amenities to the vertical rise of the brick buildings.

|

|

| American Tobacco Campus Historic Redevelopment, Durham, N.C. |

Functionally, brick provides a durable surface that requires minimal maintenance. Its inherent compressive strength works well with both pedestrian and vehicular applications. Additionally, clay pavers’ ability to be installed in a number of different systems gives designers and contractors several options that can all achieve outstanding results.

Today, one company’s vision to rejuvenate a community has come to fruition with the successful redevelopment a mixed-use “work, play, and live” campus. The new environment has served as a catalyst for the area, resulting in continued renewal in the surrounding areas. In short, this project is an outstanding example of building re-use and epitomizes New Urbanism.

|

![]()