April 2016

By Christine A. Subasic, P.E., LEED AP

The LEED™ Rating System

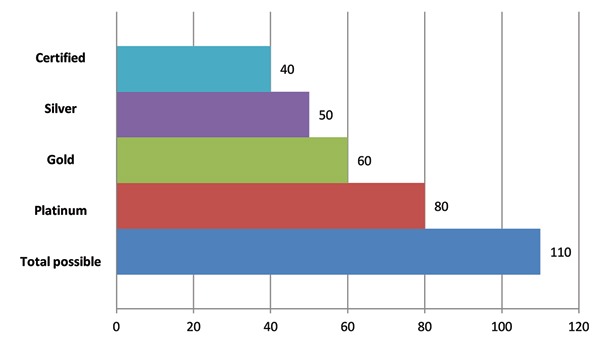

Most people in the construction industry are at least somewhat familiar with LEED™, the most widely used green building rating system in the U.S. For those who are not, LEED is a rating system designed to evaluate buildings in the areas of energy use, water use, materials use, indoor environment, the building site and location. LEED contains a total of 110 possible points distributed among 35 optional credits, as shown in Figure 1. The U.S. Green Building Council (USGBC) certifies buildings that meet enough of the LEED requirements according to the total number of points earned (see Figure 2).

In late 2013, the USGBC released an updated version of LEED, known as LEED v4, which revised many of the credits in the rating system, especially those related to building materials and products. At present, designers can use either the older rating system, LEED 2009, or the LEED v4 system. Beginning on Nov. 1, 2016, only the LEED v4 system will be available for use. LEED v4 contains the same general categories as LEED 2009, but the Materials & Resources category is changed significantly to focus on building product transparency and disclosures.

One of the other new focuses in LEED v4 is on integrated design process. The goal of this approach is to achieve “synergies across disciplines and building systems.”1 For this and other reasons, it is advisable that contractors and subcontractors familiarize themselves with the overall structure of the LEED rating system so that they can be knowledgeable partners at the table early in the design process. General information and a copy of the LEED rating system can be found at www.usgbc.org/leed. USGBC also maintains a credit library with specific requirements for each credit in all versions of the rating system (www.usgbc.org/credits).

There are three general areas that typically have a direct impact on the mason subcontractor. These are material selection, documentation and construction/installation.

Material Selection

The materials selected on a LEED project have a direct impact on earning many of the LEED credits. The most common selection factors include recycled content, regional manufacture, salvaged materials, and product transparency disclosures. All can have an impact on availability and cost. Each is discussed in more detail below.

Recycled Content

The credits for use of building products containing recycled content are among the most frequently achieved of all the LEED credits. In LEED 2009, points are based on the dollar value of recycled content in building products as compared to the total value of the materials on the project. In LEED v4, recycled content is only one part of a larger credit, and so the direct point contribution is reduced. Nevertheless, many designers consider recycled content when making their product selections.

Masonry-related products that may contain recycled content include concrete masonry units, clay brick, grout and, less often, mortar. In addition, many masonry accessories may incorporate recycled content; these include masonry anchors, cavity drainage materials and some flashing materials.

Regional Manufacture

In the LEED rating system, designers may choose building products based on their location of manufacture. Actually, both the location of manufacture and the source of raw materials are important. Both must be within 500 miles of the project site under LEED 2009, and within 100 miles of the project site in the newer LEED v4. These distances are measured as the crow flies. Many masonry materials are regionally available.

Salvaged Materials

Salvaged materials may also be specified more often on LEED projects. For masonry, these may include salvaged brick units or even sand set pavers.

Product Transparency Disclosures

LEED v4 brought many changes to the Materials & Resources section, one of the primary changes being the introduction of several points associated with disclosing information about a product’s manufacture.

Selecting products having an Environmental Product Disclosure (EPD) is one way to earn a point in LEED v4. As a result, many designers are specifying products that have published EPDs or at least published a Life Cycle Assessment (LCA). The pool of masonry products that have published LCAs or EPDs is limited, but growing.

Raw material ingredient reporting can also earn points in LEED v4, so specifiers are seeking products that have either (1) published product ingredient lists, (2) published a Health Product Declaration (HPD), or (3) published a Cradle to Cradle (C2C) certification. See the sidebar on the next page for more information on product disclosures.

In The NewsArgos delivers America’s first ready mixed concrete made with recycled carbon dioxide |

Thanks to a newly formed agreement between Argos of Atlanta, Ga., and CarbonCure Technologies of Nova Scotia, Canada, Argos was first in the United States to pour concrete manufactured using recycled carbon dioxide. Argos, a multinational cement and concrete manufacturer headquartered in Colombia, produced the concrete mix with CarbonCure’s carbon dioxide recycling technology at its Cumming, Ga., ready mixed concrete plant in early January. The leading manufacturer had been incorporating the CarbonCure technology into certain concrete mixes for several weeks and continues to undertake extensive industrial scale testing at its technical center. Bill Wagner, vice president of Ready Mix Southeast Zone at Argos USA, said, “As the concrete industry continues to shift toward sustainability, we’re excited to lead this initiative and offer products made with CarbonCure’s technology to our customers.” CarbonCure’s technology uses carbon dioxide gas captured from the smokestacks of industrial emitters to improve the compressive strength of ready mixed concrete. CarbonCure has announced a series of partnerships with ready mixed concrete producers across the United States. Argos is the first producer in the U.S. to deliver ready mixed concrete that incorporates CarbonCure’s technology to a construction site. The CarbonCure technology has been available in the concrete masonry industry since 2012. Concrete products made with the CarbonCure technology have been in high demand with architects, building developers and engineers, particularly as LEED, the world’s leading green building rating system, continues to flourish. One such architect who is leading initiatives related to sustainable design is Paula McEvoy, LEED Fellow and co-director of sustainability at the Atlanta office of the international architecture firm Perkins+Will. McEvoy explains, “As we continue to evolve our conceptualization of sustainability in building design, we encourage building material manufacturers to pursue innovations that reduce our environmental footprint. On behalf of Perkins+Will, I’d like to congratulate Argos on exploring the initiative to reduce the carbon footprint of its ready mixed concrete through the addition of the CarbonCure technology.” For more information, visit www.Argos.co or www.Argos-US.com. |

Product Documentation

Product submittals on a LEED project are generally more onerous than on a non-LEED project. Documentation is required to confirm any LEED material credit being pursued. Product submittals should include all the customary information as well as information on the recycled content, location of manufacture, and other LEED-specific information. It is usually recommended to provide all general product information as well as all LEED-specific information in one submission. In addition, because the calculation for many of these credits is based on the total value of materials on the project, the cost of the building product, as delivered to the project, but not installed, must often be provided. In some cases, the project designers may provide a template for required information.

Recycled Content

Recycled content of building products must be reported as a percent of the total weight of materials. Note that LEED distinguishes between post-consumer recycled content such as that obtained from recycled bottle glass, and pre-consumer recycled content such as fly ash. Pre-consumer recycled content and post-consumer recycled content must be listed separately.

Product Transparency Disclosures |

|

| Health Product Declarations (HPDs), environmental product declarations (EPDs) and Cradle to Cradle (C2C) certification are among the ways that LEED v4 encourages building product manufacturers to provide information on their raw ingredients and manufacturing impacts.

The Health Product Declaration® (HPD) Collaborative provides a standard format for assessing raw ingredients in a product against chemical health hazard lists. More information can be found at www.hpd-collaborative.org. Environmental product declarations (EPDs) are used to provide a report of the environmental life cycle impacts for a building product. EPDs are based on a life cycle assessment of the product and follow international standards and national product category rules. Cradle to Cradle certification is a program of the Cradle to Cradle Products Innovation Institute. It certifies products to be free of certain hazardous chemicals. More information can be found at www.c2ccertified.org. |

Regional Manufacture

The distance from the project site to the location of manufacture and the source of raw materials should also be reported. In most cases, it is sufficient to note whether the product has raw materials sourced and manufactured within 500 miles of the project site (if LEED 2009) or within 100 miles of the project site (if LEED v4). Note that the distance from the specific manufacturing location is required. If a product is manufactured in multiple locations, the one used to source the specific project must be used. All distances are measured as the crow flies.

VOC Content

LEED projects pursuing indoor environmental quality often require selection of products containing no or low volatile organic compounds (VOC). In this case, product submittals must include test data showing compliance with the LEED requirements. Stone, ceramic, glass, concrete, and clay brick masonry materials are considered fully compliant without any VOC emissions testing if they do not include integral organic-based surface coatings, binders or sealants. In this case, confirmation of ingredients may be necessary.

Product Disclosures

If a selected building product has an EPD, HPD or other form of product transparency disclosure, a copy of the declaration should be provided as part of the product data submittal.

Construction

On a LEED project, it is especially important for the subcontractor to clearly understand the general contractor’s expectations for construction and installation. Many LEED credits are entirely dependent upon proper execution of the construction requirements. Seemingly minor mistakes can result in the loss of a LEED credit and can significantly impact the project.

One common credit relates to construction waste management. This credit requires documentation of construction waste diversion. Nearly all masonry materials are recyclable. This includes masonry units, strapping, pallets and other packaging, and metal accessories and reinforcement. LEED projects may use either commingled recycling or sort-on-site recycling. In either case, strict adherence to proper recycling is important to achieve the project LEED goals.

A permeable paving system is another area requiring careful attention. On a LEED project, permeable pavements may be used to reduce stormwater runoff and reduce the heat island effect. Proper installation is essential in achieving these LEED credits.

Conclusion

LEED projects benefit from all parties having an understanding of the LEED rating system and in particular the LEED credits related to their specialty area. Check out the resources listed below for further information on the ways masonry can play a role on LEED projects. On a LEED project, a knowledgeable mason contractor can be an asset to the project by providing information on product availability and costs, supplying timely and complete product data submissions, and adhering to construction requirements.

1 LEED Reference Guide for Building Design and Construction, U.S. Green Building Council, Washington, DC, 2013.

Resources on Masonry and LEED

• Masonry Is Sustainable, The Masonry Society, Longmont, Colo., http://www.masonrysociety.org/html/resources/Sustainability_Brochure/TMS_Sustainability_Brochure-2014-10-10.pdf.

• Subasic, C., LEED v4: New Categories and Credits Shake Up Ways of Contributing, SMART dynamics of masonry, Vol. 1, No. 4, 2014, http://www.dynamicsofmasonry.com/content/leed-v4.

Product to WatchGreencore USA Elevates Environmental Building Standards With New High-Yield Mortars, Stuccos and Grouts |

| Driven by client demand and environmental regulation, green building continues to double every three years, according to the World Green Building Trends 2016 report by Dodge Data & Analytics. In an effort to help contractors, architects, engineers and specifiers better fulfill this growing responsibility; Greencore USA offers a full line of high-quality, high-yield and environmentally friendly cementitious building materials. All of the mortars, stuccos and grouts from Greencore USA, a QUIKRETE® company, are manufactured using a unique combination of slag cement and Portland cement to increase the environmental benefits on a project while improving productivity and reducing costs.

Jorge Chiappo, product developer and a sales manager of masonry products in Florida for Greencore USA, said, “Recycling is the most fundamental benefit of using slag cement, which is the post-consumable remains in the process of transforming iron ore into iron. Replacing a percentage of Portland cement with slag cement not only keeps waste out of landfills, it reduces the amount of energy required to manufacturer Greencore USA products. In addition, due to the superior working characteristics of the product(s), contractors gain about 25 percent more working area with Greencore USA mortars, stuccos or grouts.”

Greencore USA Core Fill Grout — A blend of Portland and slag cement, dried sand and gravel, and other proprietary ingredients, this core fill grout meets ASTM C476 when properly mixed in the field with water. Available in fine and coarse grades, Greencore USA Core Fill Grout can be specified in a variety of compressive strengths from 2000 psi and above. Greencore USA products, which are currently available in California and Florida, provide quantifiable environmental benefits that can contribute to U.S. Green Building Council LEED certification. For more information on this environmentally friendly Greencore USA mortars, stuccos and grouts, visit www.greencore-usa.com. |

Greencore USA Super High Yield Mortar — An ecologically-friendly, high-performance blend of Portland and slag cement, dried sand, and other proprietary ingredients, this mortar meets ASTM C270, C1714, and ICC requirements for masonry mortars when properly mixed in the field with water. Available as type S or M, Greencore USA Super High Yield Mortar can be used for non-load-bearing applications above or below grade in a variety of custom colors.

Greencore USA Super High Yield Mortar — An ecologically-friendly, high-performance blend of Portland and slag cement, dried sand, and other proprietary ingredients, this mortar meets ASTM C270, C1714, and ICC requirements for masonry mortars when properly mixed in the field with water. Available as type S or M, Greencore USA Super High Yield Mortar can be used for non-load-bearing applications above or below grade in a variety of custom colors. Greencore USA Super High Yield Stucco — An ecologically friendly, high-performance blend of Portland and slag cement, dried sand, and other proprietary ingredients, this stucco meets ASTM C926 requirements for a scratch, brown or finish coat when properly mixed in the field with water. Available in coarse, medium and fine grades, Greencore USA Super High Yield Stucco can be applied in both three-coat stucco wall systems and the brown coat and finish coat in two-coat wall systems over masonry and concrete.

Greencore USA Super High Yield Stucco — An ecologically friendly, high-performance blend of Portland and slag cement, dried sand, and other proprietary ingredients, this stucco meets ASTM C926 requirements for a scratch, brown or finish coat when properly mixed in the field with water. Available in coarse, medium and fine grades, Greencore USA Super High Yield Stucco can be applied in both three-coat stucco wall systems and the brown coat and finish coat in two-coat wall systems over masonry and concrete.