June 2016

Manufactured Stone

By Jan Boyer

Photos courtesy of the Cast Stone Institute

If it looks like stone and is a manufactured concrete product, then it must be Cast Stone, right? Not true. The product could be Cast Stone or one of a number of other products, including adhered manufactured stone masonry veneer (AMSMV), architectural precast, calcium silicate, natural stone or even new lightweight products made with only an outer coating of concrete. Each product has its appropriate applications dependent upon the project.

If it looks like stone and is a manufactured concrete product, then it must be Cast Stone, right? Not true. The product could be Cast Stone or one of a number of other products, including adhered manufactured stone masonry veneer (AMSMV), architectural precast, calcium silicate, natural stone or even new lightweight products made with only an outer coating of concrete. Each product has its appropriate applications dependent upon the project.

This article discusses Cast Stone — what it is, how it is specified and how to determine quality Cast Stone production, and new, upcoming standards for installation.

What Is Cast Stone?

Architectural Cast Stone is a refined architectural concrete building unit manufactured to simulate natural cut stone and is used in unit masonry applications. In other words, it is a unit installed by a mason.

Used as an architectural feature, trim, ornament or veneer for buildings or other structures, it is created with a fine-grain texture to simulate all types of natural cut stone, including but not limited to limestone, granite, slate, travertine or marble. Cast Stone can be made from white and/or grey cements, manufactured or natural sands, carefully selected crushed stone or well-graded natural gravels, mineral coloring pigments and admixtures to achieve the desired color and appearance while maintaining durable physical properties which exceed most natural cut building stones.

Cast stone is generally non-structural and anchored to load-bearing masonry wall systems in traditional commercial and residential buildings and other structures. It is also used in numerous hardscape applications and is often the material of choice for restoration projects, where it can easily replicate original intricate, natural stone pieces. The many uses of Cast Stone are depicted at www.caststone.org/photographs.htm.

Proper Specification of Cast Stone

Cast Stone is specified to be manufactured to meet or exceed standards as per the current version of ASTM C1364, Standard Specification for Architectural Cast Stone, which originated in 1997. This document contains very specific requirements for the physical properties, testing, appearance and tolerances for Cast Stone. These requirements are applicable whether the product is manufactured by dry tamp, wet cast or machine made methods.

ASTM C1364 is referenced, beginning with the 2012 International Building Code, as the definition for Cast Stone and is therefore legally binding in jurisdictions that have adopted the building codes.

Cast Stone requirements in ASTM C1364-16 are:

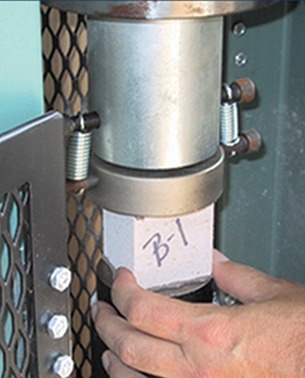

- Compressive Strength. ASTM C1194, testing in 2-inch cubes: 6,500 psi minimum for product at 28 days.

- Absorption. ASTM C1195, testing of 2-inch cubes,

6 percent maximum by the cold water method only

at 28 days. - Freeze/Thaw. ASTM C1364, of less than 5 percent after 300 cycles of freezing and thawing. Of note is that Cast Stone is the only product with a freeze/thaw requirement that must be met by all manufacturers. The passing of Cast Stone by this test relates to over 60 years of durable product life.

The Cast Stone Institute does not simply make industry recommendations. We work within recognized reference standards to assure the specifier of the highest-quality Cast Stone for a project.

Cast Stone Production Methods

According to ASTM C1364-16 standards for Architectural Cast Stone, Cast Stone can be produced in dry tamp, wet cast or machine made methods. No matter the method, the Cast Stone must comply with all of the testing minimums in order to be compliant with the specification. Therefore, any method of production can provide quality cast stone. ASTM C1364-16 specifically states that the method of production be chosen by the manufacturer and not the specifier. This would include the mason contractor.

Cast Stone manufacturers produce under one, two or all of these methods depending on the company. Why the different methods if they are all under the same technical standards? There are circumstances where the production by one method would be more beneficial for a specific project, and the manufacturer is the best entity to make that determination. Just as the specifier knows what they need to comply with various building codes and standards and how the Cast Stone is intended to function on the wall, so does the manufacturer know how best to produce the Cast Stone to meet these performance criteria.

For more guidance on this issue, reference the Cast Stone Institute Technical Bulletin #54, available for free download at www.caststone.org under “Technical Resources > Technical Bulletins.”

Cast Stone Institute Plant Certification

Recognizing the importance of quality Cast Stone production to the viability and longevity of a structural or landscape project, the Cast Stone Institute developed a plant certification program 15 years ago. Over the years, this certification program has been enhanced to make it one of the most rigorous certification programs in the construction industries. The CSI Certified Producers take great pride in the production of exceptional Cast Stone for each project for which they supply material.

In order for a non-certified producer plant to be considered equal to a CSI Certified Plant, there are very specific and very important criteria that a specifier should require as documentation. Simply stating that a plant complies with CSI Certification Guidelines is absolutely not enough.

Prior to admission, each potential Producer Member must submit to a rigorous examination of product quality, safety, testing (including freeze/thaw), meticulous record keeping and financial viability of the company. Once certified, they undergo the recertification process every other year with unannounced inspections and test data reporting every six months, in addition to numerous other requirements. Complete details about the tests can be found at CSI’s website, www.caststone.org.

10-Year Product Warranty

The Cast Stone Institute Producer Members adopted language for a 10-year limited product warranty in 2011. CSI Producer Members are aware of the evolving environment for products that demand sustainability, durability and usable service life. This warranty demonstrates that CSI Producer Members embrace these principles and produce a product that will stand the test of time.

Refer to CSI’s website for complete technical information, details, Or Equal and warranty documents.

New Cast Stone Standards Coming Soon

The Masonry Society, the organization that creates the standards for the masonry industry, is in the process of finalizing new Standards for Cast Stone design, production and installation. This important standalone document will be an invaluable resource to architects, engineers, Cast Stone producers and masons. These mandatory guidelines will be available through The Masonry Society and included in the 2018 version of the International Building Code. Once the new standards are finalized, training sessions will be held for masons.

For more information, including educational opportunities, contact the CSI office at staff@caststone.org or (717) 272-3744.

Jan Boyer has been the executive director of the Cast Stone Institute since 2006. She currently serves on the board of directors for the Masonry Alliance for Codes and Standards (MACS) as board secretary and serves on several administrative committees for The Masonry Society. She also sits on the ASTM C27 Committee under which Architectural Cast Stone falls. She can be reached at jboyer@caststone.org.