Technology

Though the technology has been in place for some time, use of Building Information Modeling (BIM) is quickly gaining in popularity and promises to change the construction, engineering and architecture industries forever.

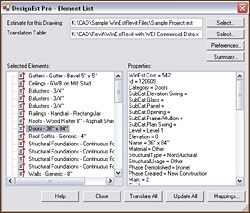

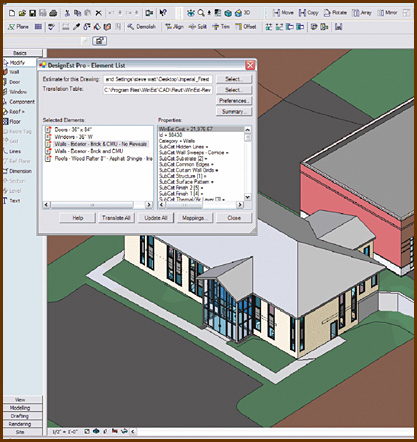

Building Information Modeling, or BIM, allows all parties involved in a building project to simultaneously create one 3-D computerized model of an entire building before the first bulldozer of dirt is ever moved. The result is a digital model that includes both the physical and functional aspects of a new building.

Building Information Modeling, or BIM, allows all parties involved in a building project to simultaneously create one 3-D computerized model of an entire building before the first bulldozer of dirt is ever moved. The result is a digital model that includes both the physical and functional aspects of a new building.

Chuck Eastman, professor of both architecture and computing, as well as director of the Ph.D. program in the College of Architecture at Georgia Tech, says the technology used by BIM is similar to that used for the last 10 years at the fabrication level by steel, piping and other specialty sectors of the construction industry.

“It’s being picked up aggressively now, and the transition is being made faster than CAD picked up in the Ô80s and Ô90s,” he says. While gaining in popularity across a number of sectors, BIM use by the masonry industry has been slower, though Eastman has participated in some BIM projects utilizing pre-cast and reinforced concrete.

BIM is especially useful with regard to full brick masonry by providing a more accurate count and cost, especially where thin face brick is concerned when trying to determine the number of cover pieces versus more expensive corner pieces, adds Eastman.

Eastman cites a 2006 survey by the American Institute of Architects that reported 20 percent of firms surveyed had completed a project using BIM, and 75 percent overall planned to use BIM in a project sometime in the next year.

“But the percentage of projects overall being done with BIM is still much lower than that,” and could be as low as one in 20 projects, he says.

BIM allows all conflicts to be resolved early on and, theoretically, will wipe out any need for change orders and requests for information, says Deke Smith, executive director of the Building Smart Alliance at the National Institute of Building Sciences in Washington.

The concept, an international effort, has been around about 10 years, he says, and its creation is overseen by the International Alliance for Interoperability.

“It’s more than just a software, really, it’s a whole culture change of collaboration, interoperability and being able to share information,” says Smith, adding that the use of BIM provides a 12-to-1 return on investment, with savings stemming from time saved and problems corrected on the computer before they ever reach the worksite.

In addition to problems, another thing BIM keeps away from the worksite is excess materials, which can add up to wasted cost and more concern for safety on the site. While the steel, electrical and HVAC sectors have been involved with the evolution of BIM for a number of years, masonry has not been brought into the mix as much.

“The masonry industry is probably an area that we need to get more involved and help them understand how they’ll be involved from the structural side,” says Smith.

Smith says a major effort is being made now to establish an open standard, whereby all facets of the industries have a standard for communication through email and Internet, among other issues. Establishing 100 percent code compliance is another area being perfected, he adds.

“That way, it doesn’t just check the favorite code compliance item of whatever inspector there is, so this will increase public safety,” says Smith.

Smith admits that, despite the number of years behind the development of BIM, confidence in the information is low and each player in a project typically ends up re-gathering the information, a waste of both time and money.

“We’re working on educating a new group of designers, constructors and everyone else,” he says. “We’re looking at providing better information to building owners and operators.”

Smith estimates a savings of $399 billion a year in design and construction costs with the use of BIM, an amount well worth pursuing.

Those who are ready to move to BIM will need to dig deep, as the computers and graphics programs needed to run the programs cost about $10,000 each, says Larry Anderson, associate principal of TEECOM Design Group, of Oakland, Calif., which has used BIM for the past two years on large, complex health care projects and is now integrating it into smaller projects as well. His company spent an estimated $15,000 per workstation for software, hardware and initial training.

“You need a real powerhouse, but even with that, the software tends to run a little slow because there is so much information in 3-D working,” he says.

Training staff on BIM has also been an issue, though several programs exist to assist with that task. “Depending on which software you implement, there could be a high training component for your company.”

Anderson is seeing a strong push for use of BIM coming even from building owners, many of whom won’t award bids anymore to companies not using BIM. And, while progress has been good, there are still some incompatibility issues with BIM software, which can cause glitches with the 3-D models such as doors dropping out and layers of the design or text missing.

“We’re still early in this game, and the software is still catching up,” Anderson says. “We’ve always had those issues with 2-D if anyone was using anything other than AutoCAD software. There are just more things that can go wrong with BIM.”

Whereas the 2-D model method required the development of a drawing package, the BIM movement brings architects and engineers together with contractors much more easily now. Masonry contractors involved early in the game, for example, would recognize if conduit or duct work is going through a wall that isn’t coordinated correctly to fit, according to Anderson.

Under past methods, “if an error was caught during construction, the contractor has already bid the job. So, if it’s a major change, it became a change order for the owner and additional cost…[BIM] takes all layers of the model and puts them together to find conflicts,” prior to construction. An error that could have cost $50,000 during construction phase might be fixed for $1,000 or less using BIM, Anderson says.

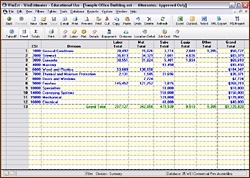

Additional software is being used by some larger contractors to create 4-D and 5-D models, with the fourth level determining cost and the fifth level setting the schedule. But these programs are expensive and use is rare at this time.

Another benefit of taking construction high tech is being able to tackle issues right on the jobsite, as many contractors are moving to the use of I-trailers, a technology trailer on the worksite where parties involved in the project can gather for video conferences and to brainstorm over the 3-D model when problems arise. Some projects even employ a tech consultant to assist with all the new technology.

“With BIM, you can also use Web presentations from any remote location, rather than everyone flying to the site to gather over a light table,” says Anderson. “It’s really changing the way we do business.

“When we went from hand-drawn paper to CAD, it was a major transition everyone had to make to stay in business so you were forced into it,” he says. “There’s another evolution happening now: If engineers and architects or contractors haven’t made the transition to BIM, they’re not going to get work.”

|

K.K. Snyder is a freelance writer based in Albany, Ga. She can be reached at kkondeadline@hotmail.com.